Lawson's "Oden Radish" Created Lawson Farm Tottori has infiltrated

Speaking of a cold time convenience store's classic menu "Oden". "Radish" which is one of its classic styles, but in the case of Lawson most of it is "Lawson Farm TottoriI am making it. Considering that Lawson has more than 12,000 stores nationwide in Japan, it is supposed to be eaten radish of several tens of thousands units a day in the winter, but what kind of place is supplying it . We showed the processing plant and further the farm.

Yonago Tottori prefecture,Yonago Kitaro AirportThere is Lawson Farm Tottori about 10 minutes by car from the hotel. This is a picture of Yonago city from near the farm, and Oyama is visible in the center.

"Lawson Farm Tottori" was an agricultural production corporation founded in May 2012 and is based on the Okano farm, and the farm where radishes are harvested and the processing plant are united. When arriving, the boxes "Lawson Farm Daikon" were stacked up. This will also be sold as Oden by Lawson 's shop a few days later.

First we will receive white coat and sanitary hat at the office.

Of course, I also need a mask.

And I will wear boots.

◆ Washing ~ Peeling

Warehouse where radishes stuffed in big bags were piled up

We will introduce this to a container filled with water using a forklift. Since the daikon which you harvested still has many soils, it washes off here first.

Daikon radiated into a container filled with water with a forklift - YouTube

The container has three electric blades, and we will send radishes to the next conveyor.

I'm bucking water quite well with radishes. ,

In this process large lumps of mud will fall, but we will not go shiny. It is left to the next process.

Wash radish and carry it to a building that will carry out the next process on a conveyor - YouTube

In the next building, another machine is waiting right away. I thoroughly wash away the remaining mud here.

Wash the mud that remained outside the radish with a washing machine - YouTube

Daikon became clean, first cut off because head and tail are unnecessary. This is a flowing work, so it will be in a flash.

Spat off the radish head and tail - YouTube

Due to the circumstances of the process after this, too bent radish or too big one is dropped here. However, at Okano farm, we ship radish which was unsuitable as oden radish as radish so that it will not be discarded.

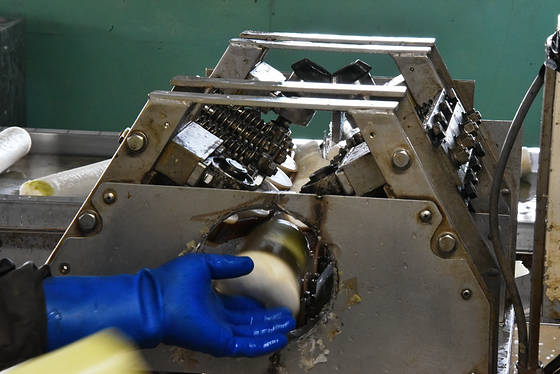

The next step is peeling off with a machine. Because it does not enter the machine if it is too bent or bigger, it will fall off here.

When you put radish in a machine, it cuts in a tubular shape while pushing the radish backwards.

From the back side, you can see that only the center part of the radish is pushed out of the cylinder.

The skin peeled off like the skin of a banana.

Radish peelers will process radish one after another - YouTube

The completed white radish is sent to the case by a conveyor.

Some radishes are broken ... ...

It seems that if it is too fresh it will be broken by shock after going through the peeler.

Daikon pushed out rapidly from the peeler - YouTube

◆ Cut ~ Packaging

Daikon which became a tubular shape of almost constant thickness peeled off will do the next processing in another nearby building.

Hand wash before entering the processing plant.

Then, disinfect the feet ... ...

I will skip the dust.

Finally into the processing plant.

What is becoming a heap of a case is a radish that was processed at the place before.

Here, work to make Oden radix finally becomes full scale. First of all, we will further cut the edge of radish in this cut state. This is not "cutting because it is an edge", but because it needs a certain size (thickness) as oden radish, it says that it omits the part which becomes thinner by all means.

Cut the end of oden radish for the next process - YouTube

Orange and purple basket at the hand of the person responsible for cutting. Orange contains things that are processed into dried radish, purple is better than orange, so it is processed into compost.

The oden radain which became a little short tubular shape is then passed through the machine and cut to a certain thickness.

Further cut radish into Oden size - YouTube

The radish that came out became "Oden Japanese radish".

The flow from cut to next step is like this.

Oden is radically cut and carried on a conveyor - YouTube

Heat with steam once so that the taste will be easy to soak in the place where it was carried.

When it comes out, it also cools with water while inspecting it here as well.

Here too radish comes out quickly, so the case will be full of radishes in a blink of an eye.

Cooling radiated radish with water - YouTube

That case itself is also waiting so much.

It is an inspection that is done in one process so far, but because it is seen with considerably strict eyes, there are things that I think as "Why is this out?"

This colored liquid is a seasoning liquid. Finally packaging is finally approaching.

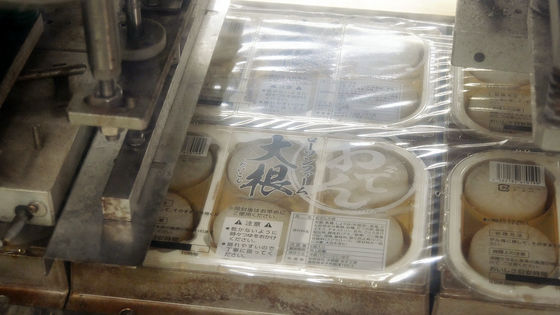

This is the packaging process.

I will put radishes steadily into containers of 6 packs.

Pack Oden Japanese radish in a set of 6 packages - YouTube

Break the radish with the next machine ... ...

Completion after pasting the film.

"Oden Japanese radish" packaging completed - YouTube

With this, we finally got to be ready to shop. ...... However, inspections are done again in the same way as it has been done in each process so far. This is out as something has entered in the pack. It is said that there is nothing to open the pack and repackage again.

"Lawson Farm Oden Polish" Last inspection - YouTube

This plant seems to process 40,000 radishes per day if it is the most frequent. As you can see, there are quite a lot of radishes that drop off on the way, but some things like "Why out?" However, because it is checking as strictly as this, the quality of Oden radish that is served at 12,000 stores is preserved.

◆ Farm edition

After seeing the processing plant, I also showed the farm that this radish was raised. In fact it was planned to see the harvest on this day, but on that day it became necessary to suddenly taro, and we had to give priority to that harvest, and the harvest of radish could not be seen. Even on a large-scale farm, I felt that the balance of work would change depending on the day-to-day demand.

The farm is located less than 10 minutes by car from the processing place.

It is the site of the Okano farm up to the building which is visible in the distance.

Okano farm all the way to the building on the other side turned back.

What is raised here is radish which becomes the basis of the Oden radish I saw earlier. Daikon sold at fruit and vegetable shops has a lot of L sizes, but one size is larger than that. After having seen the processing for oden, it is certainly convinced that it needs about that size.

A crow aiming at the radish, waiting on the utility pole. Okano-san says, "I think that poking through all this one poking because I do it all because I go to the radish next door poking a little bit," he says he plunges radishes toward the edge of the site.

It is a kite that is flying overhead.

One bird on the sprinkler. There is also a strict Nawabari here, and it seems to attack intensely when enemies come in.

There was a sprinkler stopping the crow.

Radish that I showed this time will be harvested around December. It can be harvested in about 65 days until it gets cold, but it seems that the pace of growth will change to about one hundred late harvests as cropping is delayed by one week. However, if the pace of growth is slow, it is not necessary to be impatient as it will "harvest quickly as the size becomes too big".

On the other hand, if you plant the same crop continuously, it will be harmful, so next year another crop will be made here. Daikon will be made in places making taro and etc this year. Considering that most of Lawson 's Oden radish is covered by this Lawson Farm Tottori, I think that it is possible to understand that the farmland area is about 70 ha.

In Lawson Farm Tottori, Mr. Okano tells us that because the farm and the processing plant together make oden radish, it is great that it can be advanced fresh from harvesting to processing.

By the way, Lawson 's 2015 Oden is on sale from July 31. This year, six types of soup are prepared for each area. One radish shipped from this Lawson Farm is ¥ 77 (excluding tax). Because it is low calorie as one with 11 kcal, there are many women who buy two. Because the chilling in the morning and evening is getting bigger, please warm it with oden.

2015 Oden sales started | News Release | Company Information | Lawson

http://www.lawson.co.jp/company/news/106369/

Related Posts: