The mechanism of the "Swiss Water Process" that removes caffeine only with the water that is also adopted in Starbuck's Decafe

ByKristoffer Nilsson

I like coffee and I often drink it, but the concern there is the influence of caffeine contained in coffee. Those who are interested can order ordered caffeined coffee, but you can make bean of Deca cafe (without caffeine) that is offered at Starbucks etc.Switzerland Water Process"The production method called" movie "is summarized.

SWISS WATER® Process animation video - YouTube

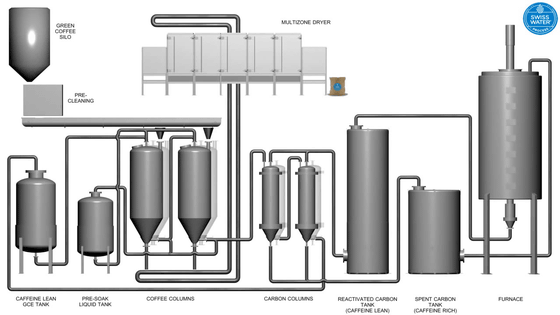

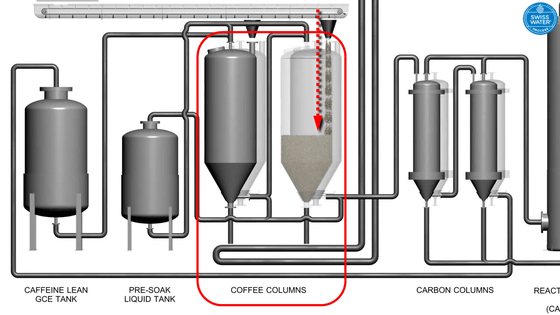

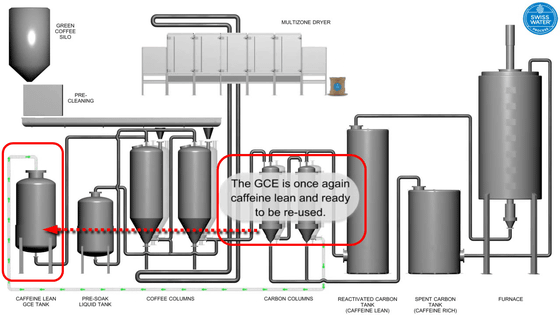

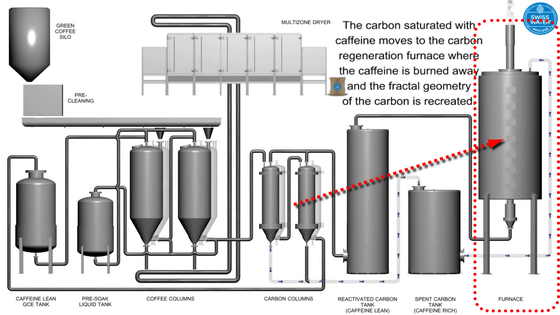

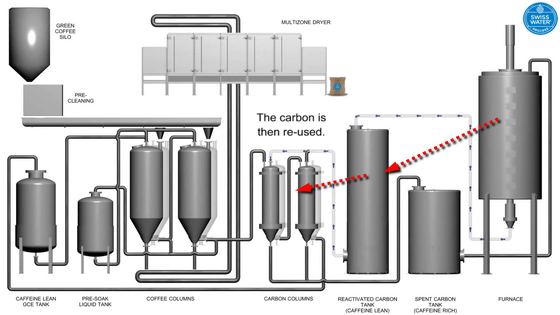

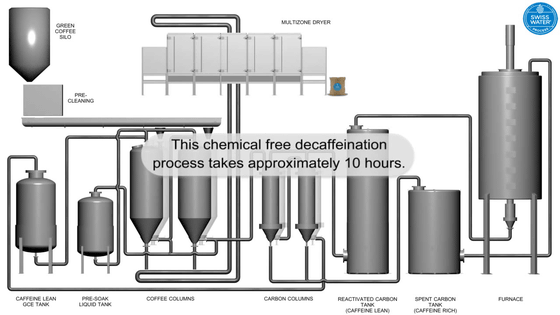

The whole system used in the Swiss water process looks like this. By sequentially circulating water in multiple tanks, we are gradually removing the caffeine from the coffee beans. Furthermore, the water after the removal of caffeine is filtered cleanly by the filter and it is also used for reuse.

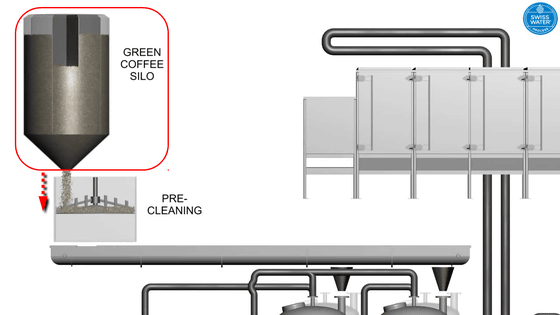

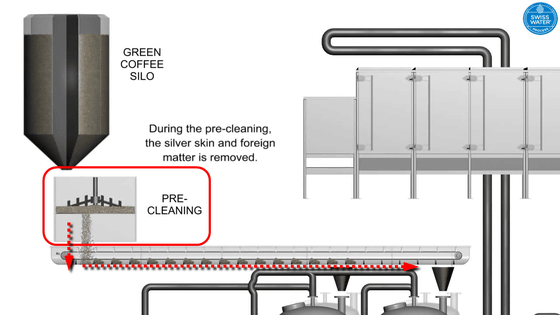

The process starts from the upper left of the image. The raw beans are transferred from the "silo" which kept the collected raw coffee beans (raw beans) to the tank for precleaning.

In the wash tank, clean skin and foreign matter adhered to the beans cleanly. The washed beans are placed on a belt conveyor and sent to the process of decaffeination.

The green beans carried on the belt conveyor will enter the decaffeination tower called "Coffee Column". It is important point later that this decaffeination tower is lined up.

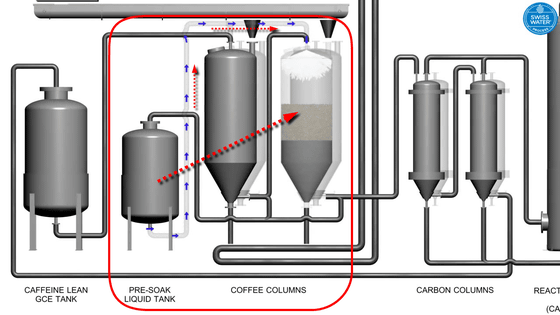

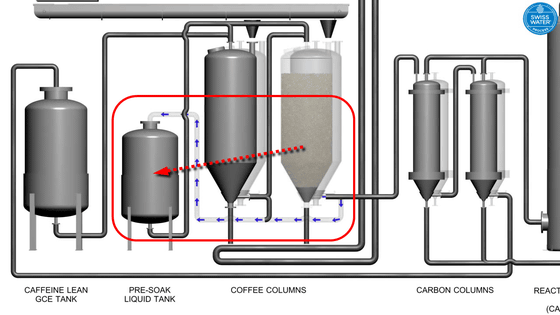

Add water to the tank containing raw beans and immerse the beans in water before decaffeinating process.

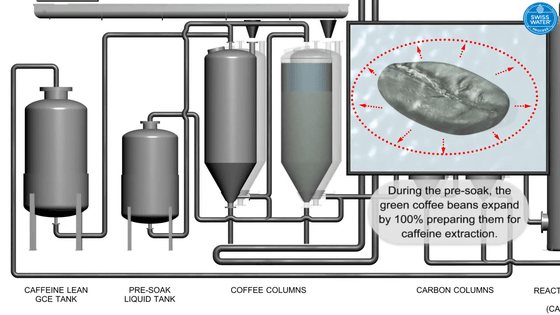

The raw beans soaked in water will swell to about twice the size, and caffeine and other ingredients will be easy to seep out.

When preparations are completed, drain water and return to the original tank.

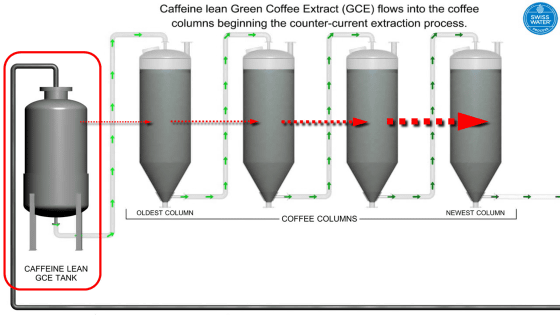

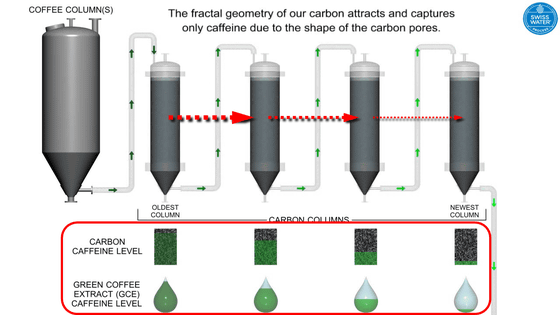

And here starts the process of actually extracting caffeine. Here, "Caffeine lean GCE (rare caffeine raw bean extract)"Liquefied liquid is used, and the ingredients of caffeine are gradually removed from the coffee beans by GCE sequentially flowing through several decaffeinated towers. In this example, four decaffeinated towers are used, it may be easiest to ask the user to imagine how new beans are thrown in order from the right and repeat the decaffeination process four times. The red arrow indicates the flowing order of GCE and the arrow thickness indicates the concentration of caffeine.

Actually, when doing this decaffeination stepAt the same time processing to return "ingredients necessary for coffee" that have been lost more than necessary to beansgoing. At this point you may not be aware of anything at all, but you should be able to grasp by considering the whole system including the process after this.

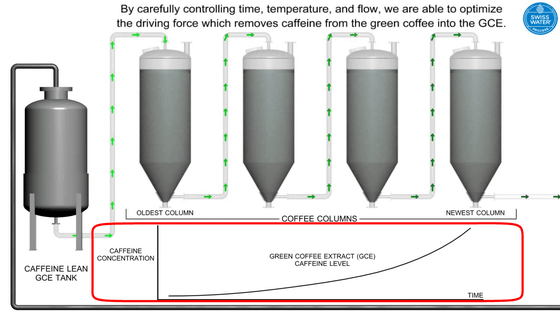

As the lower graph shows, it can be seen that the concentration of caffeine contained in GCE increases according to the flow of GCE.

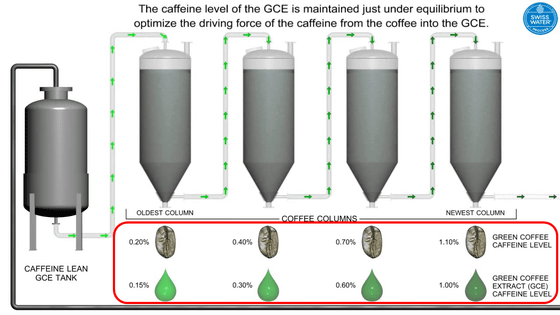

Also, as shown in the illustration, you can see that decaffeination progresses gradually as caffeine contained in beans shifts to GCE. GCE is made to flow in the order of beans (= OLDEST COLUMN) where much treatment is performed and few beans (= NEWEST COLUMN), and as the content of caffeine contained in the beans goes through the number of treatments It has become steadily decreasing.

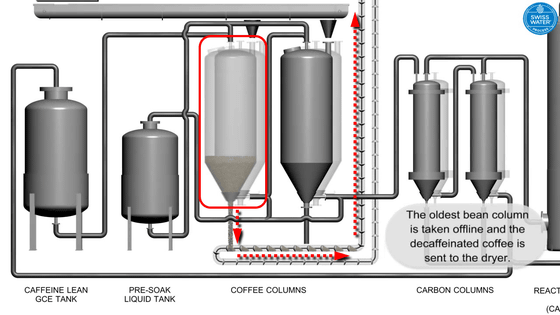

After 4 treatments, raw beans that have been decaffeinated are withdrawn from the tank and sent to the next drying process.

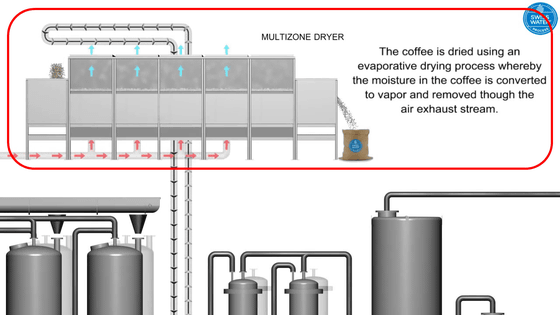

By moving the inside of a multi-room dryer with a belt conveyor, raw beans are gradually dried, and coffee beans that have been decaffeinated are completed. No roasting has been done yet at this time.

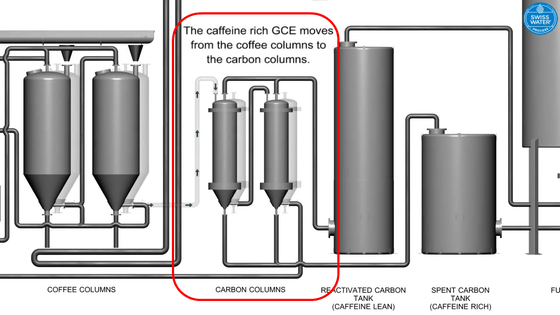

The decaffeination process of beans is completed, but the GCE used in the process is further processed from here. GCE is sent to a processing tank called "Carbon Column" which is arranged side by side, and processing to adsorb caffeine to carbon (carbon) put inside is carried out.

It is similar to the decaffeination process earlier, but this time the process of removing the caffeine contained in GCE by carbon is done. By sequentially flowing through multiple treatment tanks, caffeine contained in GCE is adsorbed in small gaps on the carbon surface and the concentration gradually decreases.

The GCE which has been decaffeinated is returned to the tank again and reused in the process of decaffeination of raw beans, but this reuse is actually an important point. Some ingredients that seeped out of raw beans in the process of decaffeination are necessary for coffee, and the original flavor of coffee is impaired from beans as it is. there,Return the caffeine only removed from the GCE to the tank again and give it to the raw beans againBy doing so, complicated processes of returning the necessary ingredients to beans are done at the same time. Since it seems that this process involves several factors such as GCE component concentration, osmotic pressure, water temperature, etc., considerable know-how should be required.

Finally, carbon treated with caffeine adsorbed is processed. Carbon is brought into the "carbon regeneration furnace" and burns the adsorbed caffeine with fire to perform the final treatment.

Caffeine-removed carbon can be reused as caffeine adsorbent. There was a cycle of reuse that was brought into the storehouse and used again to remove GCE's caffeine.

This "Swiss water process" does not use drugs, it is possible to remove 99.9% of caffeine by using only water. The processing cycle is to be completed in about 10 hours, so processed coffee beans are used in coffee chain stores or sold at stores.

You can see how the beans actually change in this "Swiss water process" by seeing the following movie.

Swiss Water® Process - YouTube

Related Posts: