Development of an airplane motor that enables the world 's first "hybrid airplane" is in progress, and a new actual machine test is scheduled to be implemented in 2015

In the automotive world, we combined the engine and electric motorHybrid carAnd do not use any more fuelEV(Electric Vehicle) has gradually increased its presence, but also in the field of aircraft "Electric airplaneThe technology development that realizes the technology is under way. A major German company "Siemens"Has succeeded in developing an electric motor for aircraft which greatly exceeds the conventional performance and the realization of the world's first passenger aircraft using electric power is gradually coming into view.

World-record electric motor for aircraft - Siemens Global Website

http://www.siemens.com/press/en/feature/2015/corporate/2015-03-electromotor.php

World-record electric motor for aircraft

http://phys.org/news/2015-04-world-record-electric-motor-aircraft.html

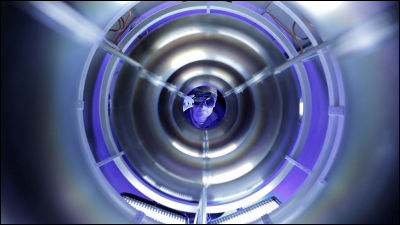

A propulsion system using Siemens aircraft motors looks like this. A motor is provided behind the four propellers, but an eye-catching compact body stands out. Its body weight is only 50 kg, it seems that it is smaller and lighter than the conventional aircraft engine due to the difference.

Here is the state of the motor itself. It is possible to obtain a high output of 260 kilowatt (kW) from the main body of 50 kg in weight. The output is divided by the weight to show the output kilowatt-number per 1 kgOutput weight ratio(Power Weight Ratio) is about 5.2 kW / kg, but this isIt is about five times as much as the conventional electric motorEven so, you can see a glimpse of its high performance.

With this "about 5 kW / kg" performance, as of 2015The world's most efficient motorIt has become. Besides, this performance is not a high power only for a moment that does not overlook the durability, but also from the fact that it is a continuous output value that can be driven steadily, you can catch a glimpse of high practicality. Thanks to this high performance,For the first time as an aircraft flying with an electric motor it made it possible to fly aircraft up to 2 tons in takeoff weight.

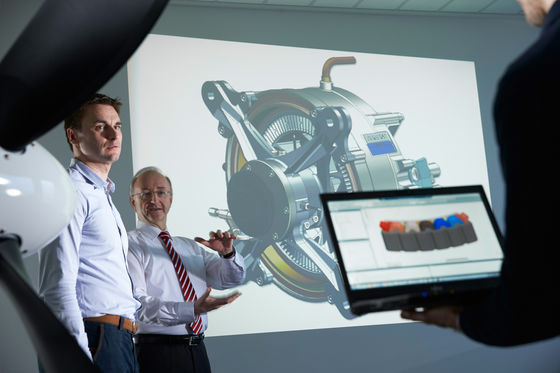

Frank Anton, head of Siemens' e-aircraft department, said, "With this technology development,Series · Hybrid systemIt will be possible to manufacture aircraft that will adopt about 4 passengers on board and fly. " Experiments with the aircraft equipped with this motor are scheduled to be carried out in 2015 and Mr. Anton about future prospects "Mr. Anton said," As a possibility of medium term, 50 to 100 classRegional machineWe are taking into consideration the use in. "

The output weight ratio of the electric motor used for industrial use is about 1 kW / kg, and it is about 2 kW / Kg in a relatively efficient automobile engine. Under such circumstances, the motor developed this time shows high performance of about 5 kW / Kg, and it is also pointed out that its performance is demonstrated at the rotation speed of 2,500 rpm. Since this number of revolutions is suitable for turning the aircraft 's propeller, it also leads to further energy efficiency by omitting extra mechanisms such as gears.

In order to realize its high performance, Siemens engineers pushed the performance of each mechanism to the limit by reviewing and optimizing all the components of the previous motor in detail. Thanks to the new simulation technology and the manufacturing technology that makes it possible to reduce weight, we are able to achieve high performance.

Motor attached to the test rig. Power to drive the motor is supplied by a small rotary engine for power generation mounted on the airframe.

Siemens has been a major aircraft manufacturerAirbusAnd small machine manufacturersDiamond AircraftIn cooperation with the development of electric airplanes, in 2013 an experimental machine equipped with a motor with an output of 60 kW "E-Star 2"We have successfully tested the flight. In the following movie you can see how E-Star 2 actually fly.

Siemens EADS DA 36 E-Star 2 - 2013 evolution @ Paris Air Show - YouTube

The engine mounted for power generation is a small one, and it does not correspond to the large output required at takeoff. Therefore, at takeoff and ascent, it is designed to achieve high output by discharging the electricity stored in the battery mounted in the aircraft at a stroke. Once it enters the cruising attitude, the electric power necessary for flight is reduced, so it seems that it realizes high efficiency and weight saving by charging the electricity generated by excess power generation capacity to the battery.

It seems that electric airplanes, which were thought to be difficult with conventional technology, are getting gradually approaching the stage where their practicality gradually comes into view. On Siemens' page, multiple images including the images in the article are published, and it is interesting for those who are interested.

Press Pictures - Siemens Global Website

Related Posts: