Campus note factory supporting Japan's manufacturing is full of Kokuyo's commitment

About 90% of Japanese have used it"Campus note" is a thorough sticking to development and plannersAlthough it is a reason that Kokuyo's commitment to manufacturing is seen even in the bookbinding process, there is actually a campus noteKokuyo Industry ShigaI went to visit the manufacturing process.

Information on factory tour | Kokuyo Industrial Shiga

https://www.kokuyo-shiga.co.jp/csr/kps_factorytour/

When I got off the lake east Misan exit of the Meishin expressway, I found a signboard of Kokuyo Industrial Shiga.

Following the sign that was on the Meishin Expressway a few minutes to the road, we arrived at Kokuyo Industrial Shiga.

This is the Kokuyo Industrial Shiga which I will visit this time, it manufactures most of the 300 kinds of campus notes at the factory in the facility and it is the largest note factory in Japan with more than 100 million volumes of annual production volume.

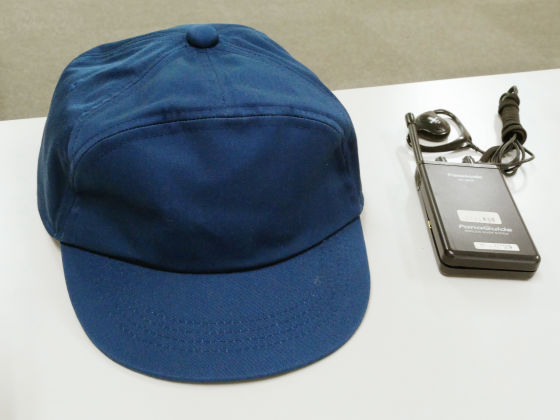

To watch the campus note factory, it is essential to wear a hat and a transceiver to be handed.

It is the start of the factory tour finally, passing through the door which the colorful campus note was designed.

Astonishing at the moment of opening the door is a tremendous mechanical sound. Because I can hardly hear the voice of the neighbor, I turn on the transceiver.

We started exploring in the factory while being hooked to machines and cardboard boxes that I had never seen before.

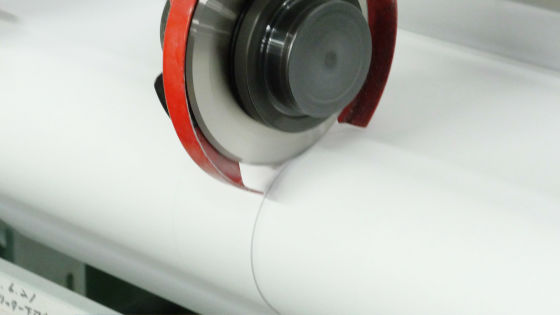

In the tour it was said that all the manufacturing process of the notebook could be shown, the first thing I was told was a machine to wind up huge roll paper. Of the roll paper that is set on the top and bottom two, the one on the top is taken up at high speed.

The state that the roll paper is being wound up can be confirmed from the following movie.

Campus notes roll paper is being taken up at high speed - YouTube

Manufacture of campus notes begins with rolling up roll paper to print ruled lines, roll material as a material rolls in the factory.

Roll paper weighs 450 kg, length is about 9 km, diameter is 1.2 m, and it is about 4700 B5 size notes in one.

In the factory I also saw an employee who was rolling heavy roll paper roll and carrying it.

The wound roll paper goes to the printing process.

This is a machine that prints ruled lines on roll paper, it is a masterpiece that the paper is printed at a speed that does not stop even on the eyes.

You can check the way the ruled lines are printed at high speed on roll paper from the following movie.

A ruled line is printed at high speed on roll paper which becomes the inside paper of campus note - YouTube

The printed paper is cut to the specified size.

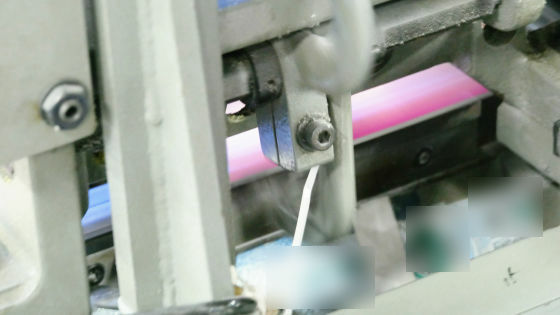

In the image it seems to stop, but in reality both the circular cutter and the paper rotate at a tremendous speed. It is the momentum to be disconnected soon after you notice it if your finger hits.

You can check how the circular cutter cuts paper at high speed from the following movie.

A circular cutter cuts campus note paper at high speed - YouTube

Next is a process of folding the cut paper into two and cutting it to the length of three notes.

Folded and cut paper will come out of the machine and will be carried. It is said to be called "middle paper" for the first time to become the contents of the note from this state.

Some of the blank sheets are chosen randomly and checked for proper printing / cutting.

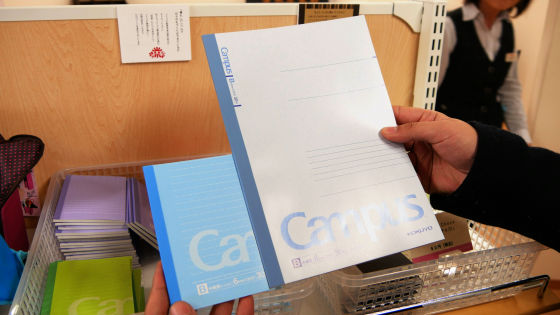

The actual inside paper looks like this.

It is said that the ruled lines on the front and back are not shifted by light and careful check work is done every 30 minutes.

In the factory I found a slogan "Let's buy it and make it."

The trimmed cut paper is placed on a machine like a belt conveyor ... ...

Proceed to the process of setting the cover and backing paper.

The process in which the cover and backing paper are set on the middle paper can be confirmed from the following movie.

The process in which the cover and backing paper are set on the inside paper of the campus note - YouTube

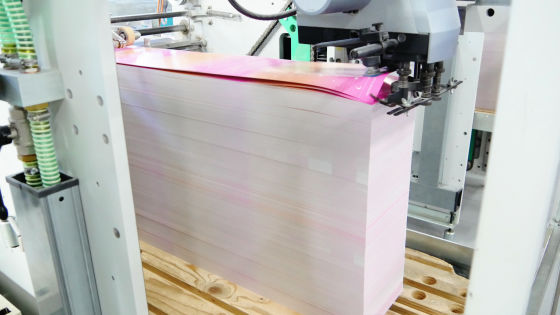

A back paper of campus notes stacked in large quantities.

It's like a sucker and only one backing paper is sucked up ... ...

"Shut" will be sent forward.

Set the backing paper so that it slides over the inside paper that passed under the machine.

The cover stands facing down, waiting for the inside paper with backing paper to come in.

The face-down cover is set sooner than the inside paper goes through the machine ... ....

That is why a blank sheet is placed on it.

The state that the cover and backing paper are set can only be admired, but it is quite untidy in the image, so it will be easy to see the process of setting when seeing the following movie.

How the backing paper is set one by one on the inside paper of the campus note - YouTube

As the word "to speed limit as soon as possible !!", the cover and backing paper set was done at a tremendous speed.

The cover and backing paper were set, and it came close to the campus note which I have seen at last. Next we go to the back compaction "back compaction" process, but before that the image machine will flip the face-down note back.

The note turned upside down turns to the backpacking process which can be said to be the essence of the campus note. The back compaction is a process of crimping the back cross with glue, a campus note which consistently adopts wireless staples instead of thread binding since the release of 1975, in order to keep the same strength as the thread binding with radio staple, Kokuyo proprietary recipe is used.

Under the back compaction being done, the back cross was rolling up rotating at high speed.

For starch consolidation using heat to paste.

Suddenly when I looked up at the ceiling of the factory, I noticed that something like an automatic atomizer was installed. This is to keep the humidity inside the factory normal, as the paper may bend if it dries too much and may not pass through the machine. Until a while ago, it seems that the floor was directly watered, but in consideration of the safety of the workers, now the mist blower is used.

Campus note came out after completing back consolidation.

Following the final corner, we are finally going to the cutting process that will become a beautiful setting.

We also pick up randomly before the cutting process, and the inspection is carried out manually. It is thoroughly checked whether there are any strange things even a bit.

Here is the machine to cut.

Cut out the unnecessary part on the outside, then cut three consecutive notes into one.

You can check the fact that the actual campus note is being cut from the following movie.

Campus notes are being cut - YouTube

The garbage that was discharged at the time of cutting is sucked up by a pipe, brought to a dedicated waste disposal site, and then recycled. Besides, it not only cuts of notes that came out at the time of cutting, but also recycled ink that became unnecessary exactly.

Looking at the pipes installed on the ceiling, you can see that garbage passes from time to time quickly.

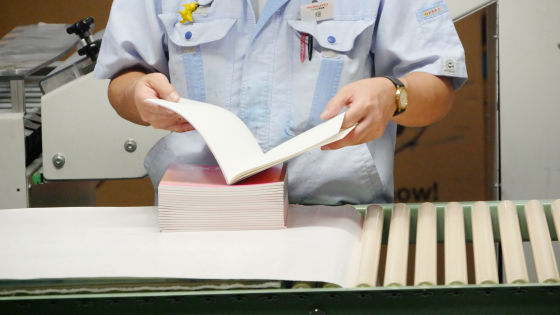

Campus notes that came out of the machine came out of the machine.

It is carried on a belt conveyor ......

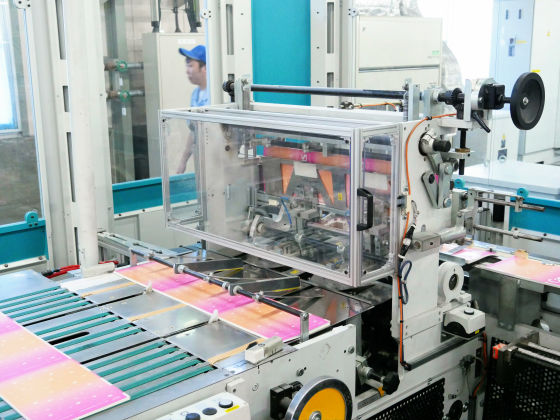

The number of books specified in the machine of the image are stacked, changing the direction.

The state that the machine changes the direction of the campus note and stacks is visible to the ground but it is indispensable process for improving work efficiency and it can be confirmed from the following movie.

How the machine stacks campus notes in different directions - YouTube

The completed campus note is carried on a belt conveyor to a predetermined position ......

It will be carried to the place where packaging work is carried out stacked with Washawasha in the designated place.

Careful checks were done to ensure that there was no incompleteness by the workers even during packaging.

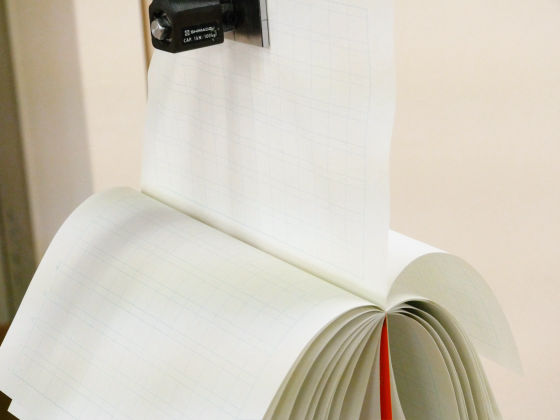

The completed Campus Note was tested as to whether the strength of the radio staple fulfills the criteria, and it actually showed it.

The test is to set the cover, backing paper and middle paper up and down and pull it, and we will test whether the PC meets the criteria by taking accurate data of strength.

Campus notes completed at the end of rigorous checks and exams.

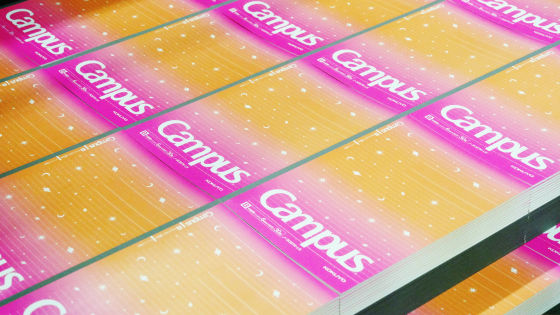

In addition, the campus note limited design that will be released in December 2014 was manufactured this time "Glitter shower"

After observing the manufacturing process of the campus note, I showed an experiment showing how hard the campus note was.

Experiment is a simple thing that fixes only one sheet of inner paper and hangs PET bottle with water under it.

A PET bottle totaling as much as 12 kg was hung up ... ...

There was never going to get the middle paper from the back cross.

Experiments using plastic bottles can be experienced at general visits.

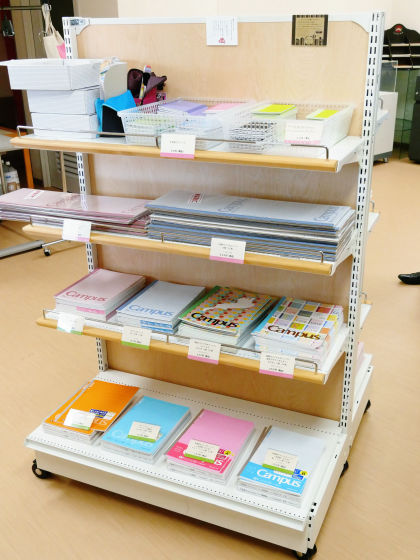

Campus Note Campus notes of factory limited sale are also popular in factory tours.

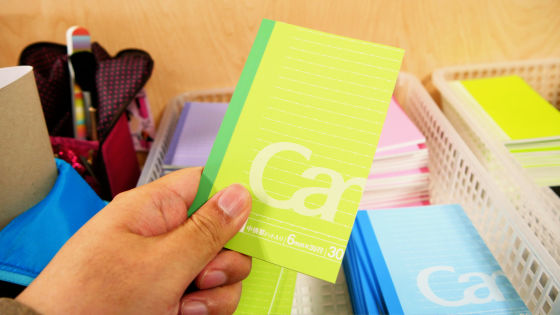

This is a "mini notebook defective item" which cut small defectively

Cute size defective mini-note is 50 yen including tax.

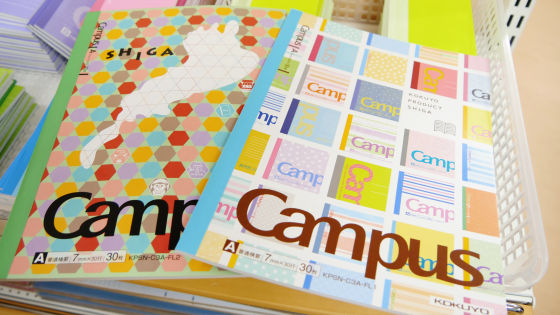

Shiga Original Campus Notes "SHIGA" and "Limited Design Gallery" are 250 yen including tax.

"2 campus note" of factory direct selling is extremely impact and 540 yen including tax.

This is the end of the factory tour of Campus Note.

The manufacturing process of the campus note is partly mechanized, but in the end it is thoroughly checked by human eyes, and it is essential that work by human hand is indispensable for manufacturing I realized that it was a lily. In the factory, tour tour for the general public is also being carried out and it is possible to actually see the commitment to Kokuyo's manufacturing, so if you are interested in it, the person who is interested in it will be casually using the campus note that I usually use casually There is no doubt that you can feel.

Related Posts: