Until a German traditional mechanical watch made by human hands and machines is made

Due to its highly developed computer technology, the computer now fits within the size of a wrist watch.Wearable device to record changes in physical conditionAs a wristwatch that is given the function of also serving as a health care as as, but basically its basic is a traditional mechanical wristwatch powered by a mainspring. A state of the workshop in the Glashütte region of Germany that still makes such a traditional watch using handwork and machines is released on YouTube movies.

Look over the watchmakers' shoulders - YouTube

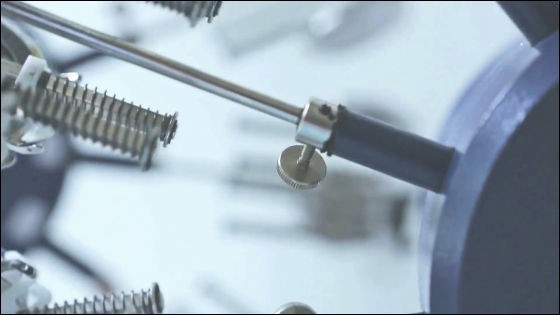

A mysterious machine made of a shaft and a spring appearing at the beginning. I feel some kind of geometric beauty.

A company building built in a quiet mountain town. Eastern town of Germany where many workshops liveGlashutteIt is located in

When metal parts are attached to the machine ......

Something like a knife is pressed from above, and grooves are made one after another.

Parts that have been processed. As for its size ......

Size enough to hold with tweezers.

Compared to the size of a human hand, I can understand its smallness. This machine digs a groove in an iron part and processes it into a gear "Hobbing machine"It was a metal processing machine called.

Numerous gears will be scraped out.

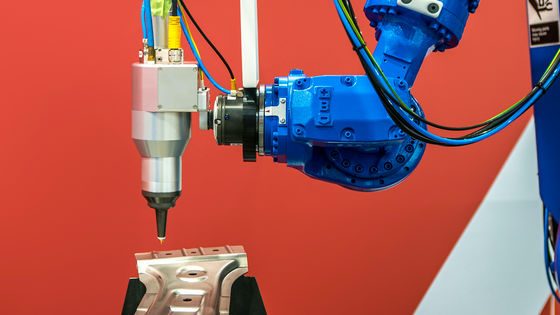

This is a machine that applies processing to the plate. The parts are set on the processing table by the robot ......

A machine with a cutting tool like a drill from the top coming down and cutting the plate with great momentum. This process is computer controlledNC processingIt seems that automation has been introduced by.

Processing was completed in just a few seconds.

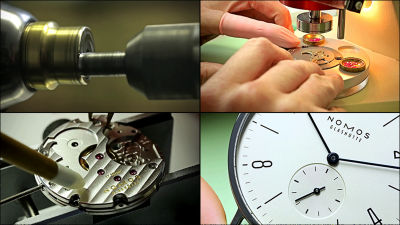

In a small hole dug in that plate, set parts like red small jewels of a few millimeters in diameter. It is a very detailed work with tweezers.

Push the stamper against it from above, and stick to the plate.

This red part is used as a bearing to fix the gear set in the watch. A clock that ticked in without a day's holiday always rotates 1440 rotations per day on the axis of the second hand while the inner part is rotating and will rotate more than 500,000 times if it is an axis that supports the power spring that generates power, Metal will wear out quickly. Therefore, the wear bearing is resistant to wearArtificial rubyMaterials such as are used as bearings.

It is a mechanism that supports parts with a latheChuckGear to be mounted on.

The polishing rod is pressed while rotating.

A spiral pattern that is born by this processing.

Repetition of fine manual work that hesitates to breathe ...

The plate was installed.

The heart of the hand winding timepiece,Balance springParts such as are set, clock to start to time clock. It is engraved with "17 STEINE" and it seems that 17 stones rubies are used for this watch.

The hands and hands are set by hand. Gently press the cylinder from above and gently fix it.

The second hand is also snapped in with tweezers.

When dull shiny metal parts are set in the processing machine ...

The laser is digging letters with enormous momentum.

With just a few seconds, the character processing of the case part of the watch has been completed.

Wristwatch completed assembly ......

It is set in a mysterious machine that appeared at the beginning, and it gets rotated round and round. This is for winding up self-winding watchesA winderMachine called.

In this way, traditional mechanical watches were built with human hands and modern machines.

This movie was founded in the Glashütte district of Saxony, Germany in 1992NOMOS Glashütte(Nomos · Glashutte) company made. The company has a mechanism that requires advanced technology "Tourbillon"Manufacturers are also working on making products incorporating old-fashioned technology and the latest technology.

Rolex and smart watch of luxury wristwatch manufacturer mergedAn image of "iRolex" is createdAlthough the fusion of wrist watch and digital technology is progressing, such as watches that continue to inscribe only in the old days, there are also charms that other models do not have in mind.

Related Posts: