Valuable movie that understands the interior of the factory which is manufacturing a "Tesla Model S" electric vehicle with a lot of robots

"Developed, manufactured and sold by Tesla Motors"Tesla Model S"Is a sedan-type electric vehicle, both exterior and interior designs are of a high-quality design, sales are also strong, and the company has achieved the first surplus as well. A movie that contains the state of the factory where Tesla Model S is being reserved in Japan has been released on YouTube.

How the Tesla Model S is Made - Behind The Scenes - The Window - Wired - YouTube

In the factory a large number of steel plates with coiled metal used for the body of Tesla Model S are lined up.

"Tesla Model S is not just a car, it is an art work," said Mr. Gilbert Passin, Vice President of Tesla Motors.

A metal coil carried by a huge crane capable of lifting up to 20,000 pounds (about 9 tons).

Next, we will pull out the steel plate from the coil using a machine.

Cut the drawn steel plate with a robot.

The cut metal panels are carried on a belt conveyor ......

It is pressed with a large machine.

The pressed metal panel looks like this.

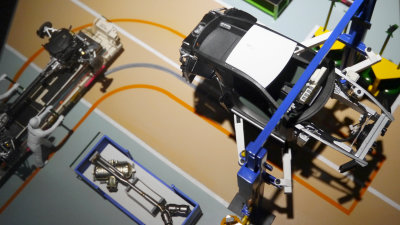

The pressed metal panels are processed by various robots.

The time required for one processing is only 6 seconds.

The robot moves metal panels with tremendous speed.

Through the above process, parts of the body of Tesla Model S are produced in large quantities.

This is where the car body of Tesla Model S is being assembled by many robots.

Robots silently doing programmed work.

Work of fine parts impossible to the robot is done by the worker's hand.

A robot carrying a large frame.

A different robot will assemble the frame that has been carried.

The car body is finally completed at last.

A robot that carries the completed body.

Next, I will paint the finished car body.

Body painted black.

Next to painting we will finish the interior of Tesla Model S.

Workers who finish the seat part.

The seat part is assembled by a robot.

A robot that fits the seat in the correct position.

This robot puts adhesive on windshield ... ...

Fit the carpet into the front part of the car body.

The total number of robots introduced in the factory is 160 units.

However, tires and ...

The part of the door is assembled by the hand of the worker, not the robot.

The final check of Tesla Model S is also done by the worker.

In this way, it is Tesla Model S that the technology of both robots and human beings are aggregated and completed.

In addition, Tesla Model S has started reservation even in Japan, and the deposit is 500,000 yen.

Related Posts: