Why is it difficult to mass produce the 155mm caliber M795 grenade used for military support to Ukraine?

by

The United States is providing military support to Ukraine in Russia's military invasion of Ukraine, which began in February 2022. However, there are limits to the military resources that the United States can supply to Ukraine, and it has been reported that it is impossible to produce enough M795 grenade shells, which are 155 mm caliber shells.

As Much As You Ever Wanted To Know About 155m Artillery Shell Production and More

https://roblh.substack.com/p/as-much-as-you-ever-wanted-to-know

There are multiple types of 155mm caliber shells, such as

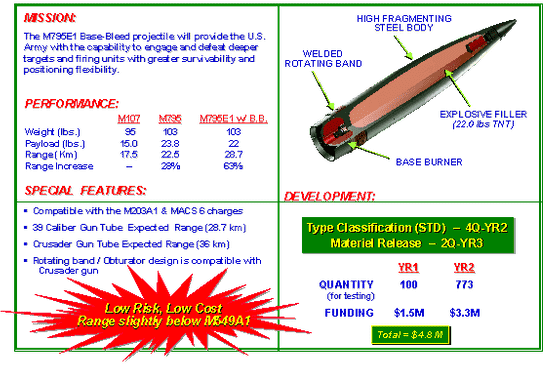

The M795 is equipped with an explosive filler and a rotating band in its steel body, and is fired in Ukraine using the M777 155mm howitzer provided by the United States and other countries, and is used to attack Russian drones and invade. It is assumed that it will be used to prevent

The M795 is manufactured at the Scranton Army Ammunition Plant in Pennsylvania and the Iowa Army Ammunition Plant , and before Russia invaded Ukraine in 2022, it was possible to produce 14,000 rounds per month. .

As of September 2023, these factories are producing 28,000 rounds per month to meet demands from Ukraine. However, Ukraine has demanded that the US increase production of the M795, saying it may use up to 600,000 rounds in some months.

The United States is building and expanding factories with the goal of producing 100,000 shells per month by the beginning of 2025, but the difficulty in producing shell casings has become a bottleneck in expanding production.

The outer shell called 'HF-1' used in the M795 is manufactured using steel made of silicon, carbon, and manganese. The basic requirements for artillery shells are that they must be strong enough to withstand the high pressure during firing and have high fragmentation properties upon explosion. M795 is said to have superior fragmentation characteristics (PDF file) compared to other shells.

On the other hand, HF-1 is manufactured through a complex process that involves multiple heating and molding processes, making mass production difficult.

Below is a video showing the manufacturing process of HF-1. HF-1 is manufactured through processes such as ``accurately cutting 20 feet (about 6 m) long iron'', ``heating the iron to about 1100 degrees'', ``molding the molten iron'', ``cooling'', and ``polishing''. .

In addition, there are almost no metal 3D printers that can manufacture and process the steel used in HF-1, and it is impossible to mass-produce HF-1 by 3D printing. Furthermore, since the outer shell is 858 mm long and 155 mm in diameter, many metal 3D printers cannot output it due to size issues. is possible to manufacture, but it takes time to output, making mass production difficult.

Engineer Rob L said, ``If the United States further expands its military assistance to Ukraine, the U.S. Department of Defense will leave the issue of licensing behind and sign contracts with many companies to expand the production of artillery shells. The next problem facing the Department of Defense is training the workforce, which has increased as the factory expands.'

Related Posts: