Osaka University announces '3D printed Kintaro candy technology' that reproduces the complex structure of Japanese beef with a 3D printer

Engineered whole cut meat-like tissue by the assembly of cell fibers using tendon-gel integrated bioprinting | Nature Communications

https://www.nature.com/articles/s41467-021-25236-9

3D printing makes it possible to reproduce even the 'sashi' of Japanese beef! -Saving the protein crisis with tailor-made production of Kintaro-ame technology --- 20210824-2.pdf

(PDF file) https://www.jst.go.jp/pr/announce/20210824-2/pdf/20210824-2.pdf

3D printing makes it possible to reproduce even the 'sashi' of Japanese beef! -Saving the protein crisis with tailor-made production of Kintaro candy technology--Osaka University Faculty of Engineering Department of Applied Natural Sciences Department of Applied Chemistry Osaka University Graduate School of Engineering Department of Applied Chemistry

https://www.applchem.eng.osaka-u.ac.jp/blog/20210825/

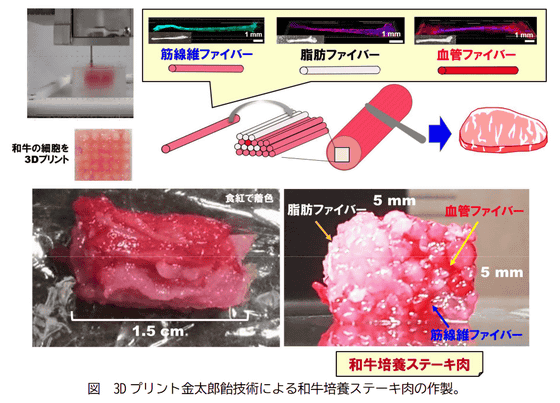

The newly announced 3D printed Kintaro candy technology is characterized by creating different fibrous tissues such as muscle, fat, and blood vessels and then bundling them like Kintaro candy. Most of the existing culture meat technology has a structure similar to minced meat composed only of muscle fibers, but 3D-printed Kintaro-ame technology can create a complex tissue structure close to real meat on a custom-made basis.

Below is how the 3D printed Kintaro candy technology is actually in operation.

First Ever 3D Printed Wagyu Beef Created In Lab --YouTube

In a demonstration test conducted in the laboratory, a total of 72 muscle fibers, 28 adipose tissues, and 2 capillaries were printed and then bundled by hand to make a meat mass with a diameter of 5 mm and a total length of 15 mm. It is said that it has succeeded. The research team says that by bundling fibrous tissue, it will be possible to reproduce a texture close to that of real meat.

The research team cites the United Nations forecast that the world population will reach 9.7 billion in 2050 as the background of this research, and the current cultured meat has a structure similar to 'minced meat' formed only by muscle fibers. Because of this, there are problems with texture and taste, so we argue that this research, which can reproduce a texture close to that of real meat, can be one of the solutions to the protein problem.

Related Posts: