A method is developed to change wood into an elastic material such as rubber.

Wood is widely used in building materials and furniture, and has the characteristics of being relatively light and having high heat insulation. In recent years,

Highly Elastic Hydrated Cellulosic Materials with Durable Compressibility and Tunable Conductivity | ACS Nano

https://pubs.acs.org/doi/abs/10.1021/acsnano.0c04298

Chemistry in Pictures: Elastic wood

https://cen.acs.org/materials/biomaterials/Chemistry-Pictures-Elastic-wood/98/web/2020/09

You can see how elastic the wood-based material developed by the research team is by looking at the GIF image below.

@LiangbingHu and his lab have made an elastic wood with rubber-like proprieties that make it perfect for bouncing like a ball. Check out the procedure in the latest #CENChemPics : https://t.co/ZnNtxznhhX pic.twitter.com / l5BUhSVYRk

— C & EN (@cenmag) September 13, 2020

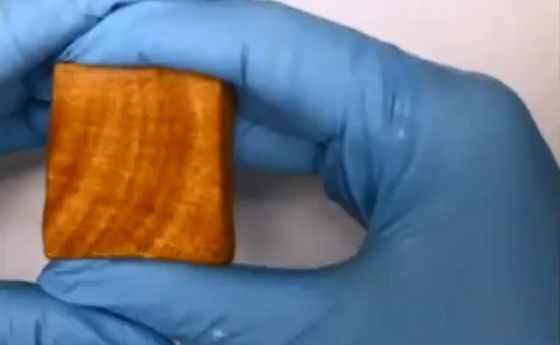

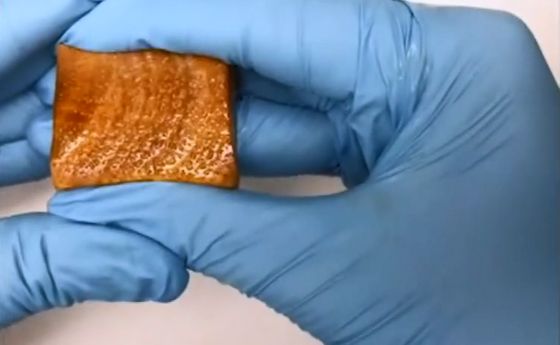

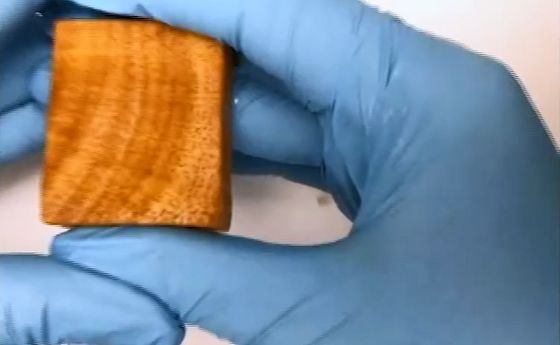

At first glance, the object held by the rubber gloves looks like cube-shaped wood ...

When I put a lot of force on my finger, it deformed and was crushed. Also, it seems that water is seeping out from the inside of the object.

When you relax your fingers, they will be restored and you will find that they are elastic.

Also, this is how the researcher threw the material on the floor.

pic.twitter.com/cT7WI51xLE — Fiik (@fiikster) September 14, 2020

Raise the spherical material higher than your head ...

If it is ordinary wood, it will hit the floor and roll ...

This material bounced like a bouncy ball.

The material hits the top of the researcher's head, suggesting that it has extremely high elasticity.

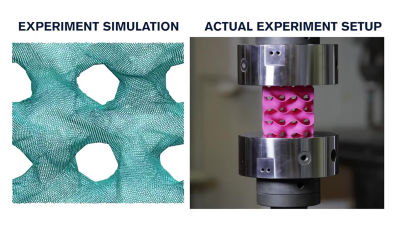

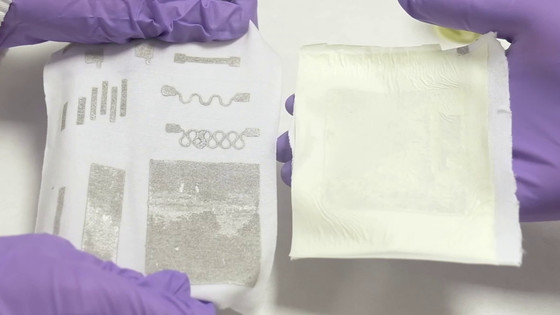

Developed by Professor Liangbing Hu 's research team, this material is made by boiling balsa wood in a solution of sodium hydroxide and sodium sulfite for several hours, freezing it for several days, and then freeze-drying it for another day. It is possible.

This procedure can scientifically break the long molecular chains of lignin and hemicellulose inside the cell wall, destroying the rigid structure of wood. Then, at the same time as the cell wall of the wood becomes thin, the fibrils that make up the fibers are released, the wood becomes soft, and it seems that it can acquire elasticity like rubber by absorbing water inside.

Wood that has acquired elasticity can withstand 10,000 compression cycles, and the conductivity can be adjusted by the compression rate of the material. The research team believes that giving wood elasticity and conductivity will expand its applications, and argued that it could be applied to sensors, soft robots, artificial muscles, energy storage technologies, and so on.

Related Posts: