An experimental plant to extract oxygen from the surface of the moon has been opened, which could be used for life support and spacecraft fuel

by

The moon has no atmosphere and cannot be breathed by astronauts who land on the moon, but it has been found that lunar sediments (regoliths) actually contain large amounts of oxygen. To develop a system for extracting oxygen present on the surface of the moon, a dedicated experimental facility has been set up at the European Space Technology Research Center (ESTEC) in the Netherlands.

ESA-ESA opens oxygen plant – making air out of moondust

https://www.esa.int/Enabling_Support/Space_Engineering_Technology/ESA_opens_oxygen_plant_making_air_out_of_moondust

Making air from Moon dust: Scientists create a prototype oxygen plant | Astronomy.com

http://www.astronomy.com/news/2020/01/how-to-make-air-from-moondust

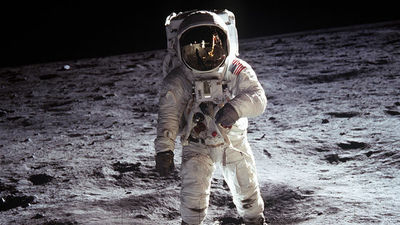

The moon has no atmosphere, but this does not mean that there is no oxygen in the moon. Analysis of regoliths brought back from the moon to the Earth by the Apollo project shows that lunar soil contains as much as 40-45% oxygen by weight.

Beth Lomax of the University of Glasgow , working with the European Space Agency (ESA) to study space instruments, said, `` Obtaining oxygen from resources found in the moon will help future lunar pioneers. It will help with both respiration and local production of rocket fuel. ' However, the oxygen contained in regolith is chemically bonded as oxides of minerals or glass, and cannot be used as it is for breathing or fuel.

ESA is exploring ways to efficiently extract oxygen from the moon's surface, and has installed a prototype of a plant to extract oxygen from regolith at ESTEC's Materials and Electrical Components Laboratory in the Netherlands. 'By having our own facilities, we can focus on research that produces oxygen from samples that mimic regolith,' commented Lomax.

by

The oxygen extraction method studied by ESTEC uses molten salt electrolysis, in which calcium chloride is placed as an electrolyte in a metal basket, and the mixture containing regolith is heated to 950 ° C. When electricity is passed through the heated mixture, electrolysis occurs, oxygen is extracted, and the remaining material is converted into an alloy. According to this process, it is possible to extract 96% of the oxygen contained in regolith in 50 hours.

The system using molten salt electrolysis was originally developed by a private company called Metalysis in the UK to produce commercial metals and alloys. Therefore, it seems that oxygen was originally just a by-product released in the production of metals, and it is necessary to make improvements in order to develop a device for extracting oxygen from regolith.

'At Metalysis, the oxygen generated by the process was an undesirable by-product, released as carbon dioxide and carbon monoxide. The reactor was not designed to withstand oxygen gas,' Lomax said. You. So, the ESTEC research team is redesigning the device to separate oxygen from regolith.

by

Oxygen extracted from regolith is expected to be used not only for breathing but also as rocket fuel. If rocket fuel can be produced on the moon, it will not be necessary to load a large amount of fuel from the earth, so the moon, which has a lower gravity than the earth, can be used as a 'gas station in space.' This will lead to a significant reduction in mission costs not only for lunar landing and reclamation projects but also for projects going to other stars such as Mars.

The research team is also exploring ways to use alloys generated during oxygen extraction. The research team is examining the type of alloy produced by oxygen extraction, whether it can be used to create parts with a 3D printer, and whether a refining process is needed to use it, but from where on the moon to collect regolith But the kind of alloy seems to change.

The team's ultimate goal is to design a sustainable oxygen extraction plant on the moon by the time the technology demonstration takes place in the mid-2020s.

by viledevil

Related Posts:

in Science, Posted by log1h_ik