A new method of releasing oxygen during aluminum refining is under development, Apple also supports research

ByU.S. Department of Agriculture

Metal aluminum widely used in life, such as airplane, car body, beer cans and smartphone frames, produces a large amount of carbon dioxide when melting and refining raw materials. While worldwide shrinking of carbon dioxide, which is also a greenhouse gas, worldwide, two major aluminum manufacturers are developing refining methods to release oxygen instead of carbon dioxide.

Aluminum production can not get much better for the environment | Popular Science

https://www.popsci.com/aluminum-apple

What is advancing the development of new technology is that of major aluminum manufacturersAlcoaAnd multinational mineral enterprisesRio TintoIt is two companies. In 19th century Charles Martin Hall of the United States and Paul Elé of France independently invented the method of refining aluminumHall-Elro methodAlthough it has been widely used, the basic method has not changed for more than 100 years, but this method has features that are difficult to overlook in the 21st century, "Many carbon dioxide is released" It is.

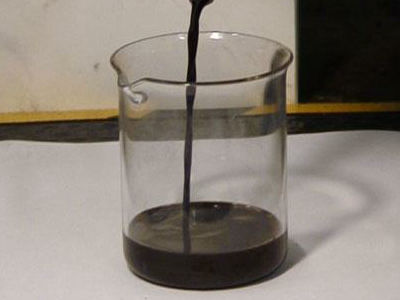

Aluminum is refined by electrolysis of raw material bauxite to become a product, but in this electrolysis an electrode made of carbon is used. Aluminum oxide is born to high purity aluminum at a high temperature of about 900 degrees Celsius. At that time, oxygen molecules released from the aluminum oxide react with the carbon of the electrode to generate carbon dioxide. It is said that the amount can not be overlooked and about 13 tons of carbon dioxide is released per ton of aluminum in the product.

ByU.S. Department of Agriculture

A breakthrough to solve this problem is about to be brought about by Alcoa discovering an inactive electrode material that does not use carbon. Alcoa does not clarify details of the material, but by using a new electrode, carbon dioxide emissions at the time of aluminum refining will be zero, conversely it will be possible to release oxygen. Alcoa, with Rio Tinto, established a new venture "Elysis" and aims to commercialize this method at commercial level.

Apple is also involved in developing new refining methods. Apple shipping approximately 80 million iPhones annually and Apple using a lot of aluminum for the frame part of products such as MacBook has invested about 10.1 million dollars (about 1.1 billion yen) in the new venture. Apple using a large amount of aluminum is considered to be involved in business activitiesCarbon footprint24% of the use of aluminum is due to the use of aluminum, and using aluminum with less environmental impact in fulfilling social responsibility as a company has a great effect.

It is around 2024 that this new technology will be commercialized, and it is still time to take time before the days when "clean aluminum" can be used close. Also, what is the new material developed by Alcoa, whether other substances will be emitted instead of carbon dioxide, electricity consumption will decrease as power efficiency decreases, carbon dioxide emissions from power generation It is important to evaluate comprehensive viewpoints such as whether the amount does not increase, but for the moment I would like to expect that new methods are being developed.

ByJAXPORT

Related Posts:

in Note, Posted by darkhorse_log