Durability test of wing bending and folding airplane wings Movie

When sitting on a window by seat on an airplane, when watching the wings turn uneven with a windy day etc. "I can not continue. drop downI think that some people have become dark, but the wings of the airplane are made to bend to a certain extent, and it is unlikely that it will break on regular flying. However, it is not designed appropriately even if it said that it turns, there are enormous manpower and budget put in there, and safe wings are produced as a result of precise calculation and design. An article summarizing movies of such wing test scenery is released.

Watch These 7 Airplane Wings Pushed to the Brink and Beyond

http://www.popularmechanics.com/flight/g2428/7-airplane-wing-stress-tests/

◆ 01: Main wing destruction test of Boeing 777 aircraft

This movie is the development scene of the Boeing 777 aircraft which Boeing sent out in 1995. It puts the appearance that the actual machine is installed in a huge testing facility, bending the wing with a great force, and actually breaking it.

Boeing 777 Wing Test - YouTube

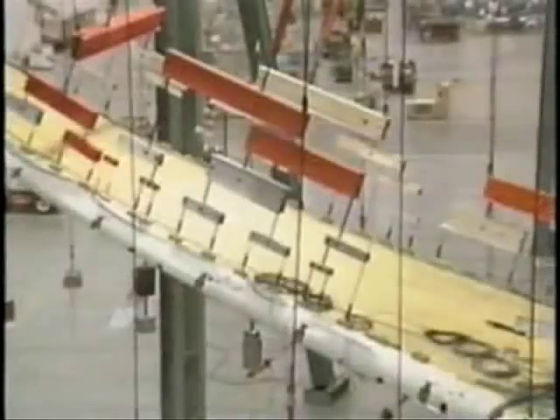

A 777 aircraft installed in a testing facility like a huge jungle gym installed in a Boeing factory. In the foreground you can see the appearance of people watching the examination situation.

It is a huge and simple test of attaching wires to the tip and middle part of the wing and examining the durability of the wing by pulling with a gauge from above.

The main wing which the wire is rolled up and gradually bends.

A considerable force has been added to the wings, and the fuselage of the fuselage is wrinkled as it is affected.

Appearance of development engineers watching over burning. A voice to read the progress of the test with the microphone sounded in the venue, and the interior was cheered for the announcement of "150%" which greatly exceeded the design limit value. It is a moment when high performance of the aircraft is proved.

However, the exam will continue. The wing which went back to the extent that it is impossible any longer. It can not be helped thought that "falling down" when it comes to the state so far.

It is as if the birds are flapping their wings. Of course it will never bend so far under normal conditions.

After that, the venue will read "151, 152 ......" the strength of the force. The moment when that numerical value was announced as "154 ......" ...

The wing broke along with the sound of "Van!" The surface of the wing was torn largely, and a number of wires and steel frames pulling the main wing were scattering.

This watching engineer also watched. In this way, the wing of the airplaneIt breaks as designedThat is why it is made.

◆ 02: Main wing durability test of Airbus A350 XWB type machine

Next is a state of main wear durability test of the latest A350 XWB type machine developed by Airbus which is a dualist with Boeing. Although the actual destruction scenes are not contained in this movie, in addition to the main wing a lot of appearance related to the aircraft body are contained.

Pushing the A350 XWB to the brink - YouTube

An A350 XWB type aircraft pulled by a towing car at night airport. Since this aircraft is a test machine manufactured at the development stage, it is not painted and the engine is not installed.

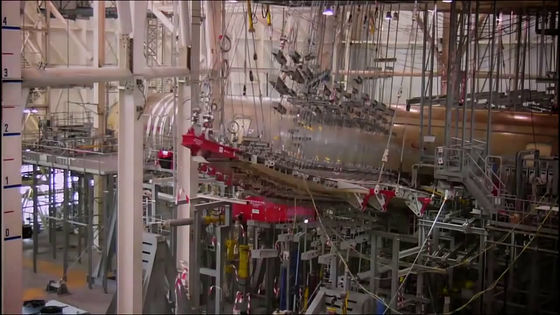

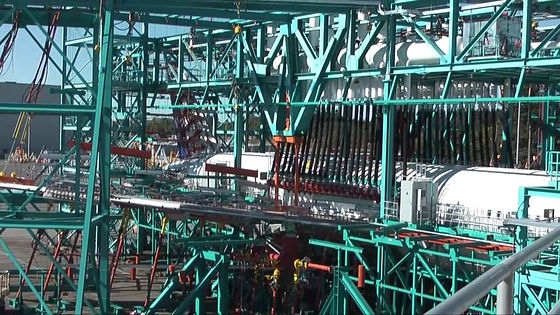

A350 XWB installed at the test site. It is set on the huge pipe stand, and the equipment for tests are lined up all around.

The test facility looks like this. It is written as "Full Scale Static Test (full scale static test)". Static test is not a flight state, it refers to a test conducted on the ground.

On the surface of the main wing, countless wires are set.

In this way, it seems that more accurate testing is done by applying force to the whole main wing. A wire is also set on the lower side of the wing, and it seems that a downward force is also applied.

When the test begins, this is also the main wing that is bent by being pulled with great force again. Although there is no actual scene to break, it is felt to prevent stress from concentrating in one place and preventing destruction from occurring by "evening" all evenly.

A red huge frame set in the aircraft. In this test, by applying the vertical force to not only the wing but also the aircraft, a situation closer to the actual flight condition has been created.

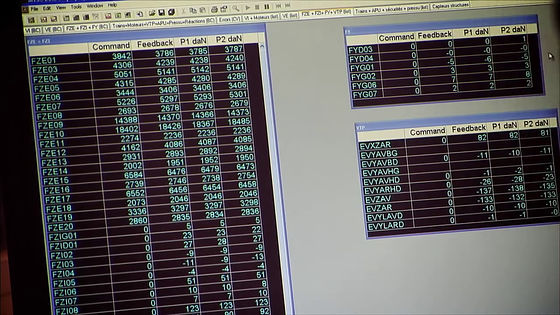

Thousands of sensors are set in the aircraft, and we will inform you of the condition of the aircraft every moment.

The main wing raised greatly. The tip seems to be lifted up to a position as high as 5.2 meters at the maximum.

An engineer supervising the exam comment on the periphery of the aircraft. The part of the audience that hits the window has something like a hose ......

This is a facility for sending compressed air to the aircraft using a hose. By raising the air pressure in the aircraft, we are going to perform the test while adding the same load to the aircraft as when flying over 10,000 meters above the sky.

The inside of the cabin is like this. In addition to seeing a pressurized hose set in the window, an iron frame which is thought to be used for testing is stretched around the floor.

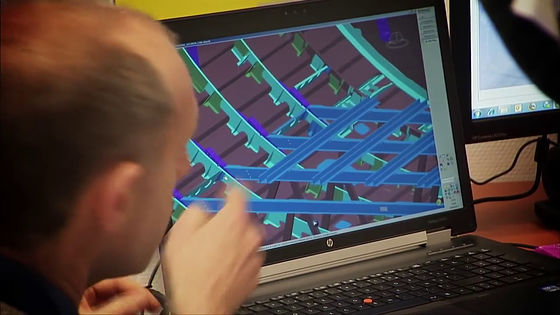

An engineer who checks the state of the aircraft with CG. Compared to the Boeing 777 aircraft at the beginning, the Airbus A350 XWB machine is said to be the aircraft that was born in about twenty years, and it seems that there is a remarkable evolution in its testing technology.

Fatigue test of 03 Boeing 787

A few years ago when the A350 XWB aircraft made its debut, the Boeing 787 was born. The following movie contains a test to reproduce the flight scene using the actual machine of the 787 aircraft and check the degree of fatigue of the aircraft.

Boeing 787 conducts fatigue testing - YouTube

It changed to last time, and this time test equipment installed outdoors. But similarly the wire and hose etc are set in the aircraft.

The purpose of this test is to confirm what kind of fatigue accumulates on the aircraft by reproducing the actual use situation rather than the strength itself. Therefore, a long time is required for the examination, and after three days of testing the test will continue for three years without stopping for a day.

Ultimately, in this test, 100,000 flights exceeding the number of times of flight until normal airplane retirement are simulated, and it is verified whether the aircraft functions as designed or keeps the durability as expected It is done.

◆ 04: FSDT (Full Scale Durability Test: Full Scale Durability Test) of F16 fighter

It is said that such durability tests are being conducted not only on passenger aircraft but also on fighter aircraft. The following movies are released by Lockheed Martin, the manufacturer of F-16 fighter aircraft.

F-16 Durability Testing: 25,000 Hours and Counting - YouTube

Although not much of the state is released, you can see how power is being applied to the wing and torso of the F - 16 installed in the rig for testing. Lockheed Martin has proven durability beyond 8000 EFH (Equivalent Flight Hours: equivalent flying time), which is the design life of F-16 fighter aircraft by conducting simulation test over a long period of time. It has achieved 25,000 EFH in July 2015, and it seems that it is supposed to verify the safety and performance of the aircraft by conducting a further long-term inspection.

The situation is also announced at the release of Lockheed Martin below.

F-16 Durability Testing: 25,000 Hours and Counting · Lockheed Martin

http://www.lockheedmartin.com/us/news/press-releases/2015/june/F16-durability-testing.html

◆ 05: 2-seater glider, DG Flugzeugbau DG-1000 model main wing destruction test

A similar test is being conducted on a two-seater glider, which is located in the opposite direction to a huge passenger plane or a powerful fighter aircraft.

Bruchversuch-a (Wing stress test) - YouTube

This test is to investigate the strength of the main wing of the DG-1000 aircraft manufactured by German glider manufacturer "DG Flugzeugbau". Because the aircraft is small, the equipment for testing is mini size as before.

However, the actual examination is the same as for airliners. In this test rig, it seems that only the main wing is set on the base and it is pulled as a gig with the wire from the top.

Test started. As the wing warped greatly ... ...

"Ban!" And wings that can break with loud noise. Even for small aircraft like a glider, it seems that the test for safety is done without any doubt.

◆ 06: This time the one-seater glider, DG Flugzeugbau DG-800 aircraft main wing destruction test

In addition, the same inspection is being carried out on a single-seat glider of the same manufacturer. As the airframe becomes smaller, it seems that blade length and chord length (= wing thickness) are getting smaller.

DG 800 Wing Stress Test - YouTube

Wings installed in the same facility. The wings that were pulled out by the Pigeon are destroyed in the same way afterwards and the data is taken.

◆ 07: F / A-18 "Hornet" Full Scale Durability Test of Battle Attack Machine

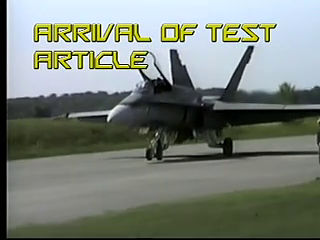

The state of the "International Follow-on Structural Test Project (IFOSTP: International Continuity Structure Inspection Project)" conducted by the Australian Defense Science and Technology Group (Australian Defense Science and Technology Group) in 1995.

International Follow-on Structural Test Project (IFOSTP) - YouTube

F / A-18 "Hornet" is a battle attack machine manufactured by McDonnell-Douglas of the United States. In addition to the US Navy · Marine Corps, it seems that the examination in Australia was done because it is adopted in the Air Force such as Australia, Spain, Finland etc.

Aircraft set in a rig for testing.

A further set of wire and hydraulic cylinder etc. are set in the aircraft, and the actual flight condition is reproduced.

I do not know where it is, but I am surprised to see how cracks are occurring. Perhaps the possibility that it is not the body itself.

Scenes that are actually turning the jet engine on the test rig are included.

In this way, safety is improved by clearing various tests for an airplane flying in the sky. The safety is said to be "safe than running a general road by car", so it seems unnecessary to worry if there is a chance to ride an airplane in the future.

Related Posts: