Succeeded in outputting glass with a 3D printer, making it possible to create amazing glass works with software control

Although it is a 3D printer that has come to be able to output not only plastic and resin objects but also cells and food,Massachusetts Institute of TechnologyBy this effort, it is now possible to output glass. By controlling with a computer, it is made to be able to make an incredibly beautiful work, but the state of its production and a lot of works are released in the movie.

G3DP Environment |

http://matter.media.mit.edu/environments/details/610

We Can Now 3D-Print Glass And It Is Entrancing

http://www.popsci.com/we-can-now-3d-print-molten-glass-and-it-entrancing

It is possible to check from the following movie how to actually make a glass using a 3D printer.

Vimeo GLASS

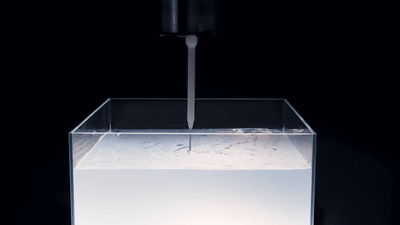

Filaments layered on many layers are sight that you often see when making things with 3D printers ... ...

If you look closely, you can see that the filaments output from the printer are shining red.

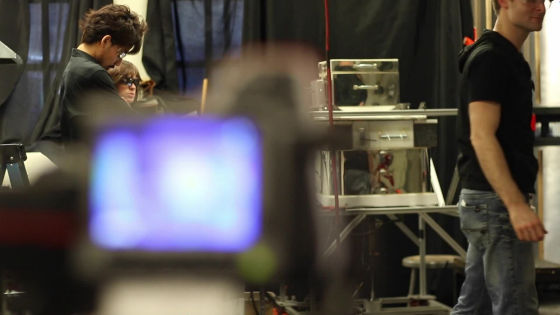

The printer outputting the object is located at the back of the following image.

In frontThermography.

Looking at the temperature, the minimum temperature is 13.1 degrees and the maximum temperature is 360 degrees. There is a red LED on the 3D printer, which seems to be quite hot.

And inside the glass it is output. The output part is red and feels hot, but the filament is transparent and beautiful.

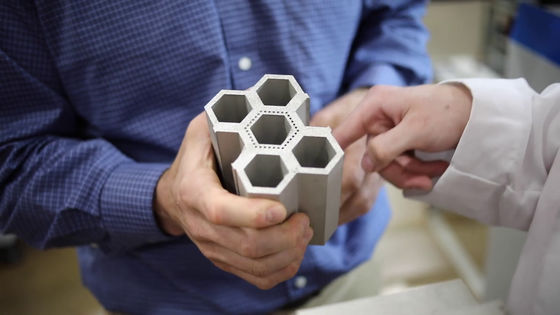

It seems that it can output even in a rather complicated form.

The design is like this.

A number of objects were designed.

Since the output is controlled by software, even quite precise objects can be manufactured.

Trying out the lid of the 3D printer and it is like this.

The 3D printer is divided into two structures, the upper part functions as a kiln, the lower part is designed to shape while cooling. The temperature of the part of the kiln is 1037 degrees, and the scenery like glass craft is expanded, which is unlikely to be a 3D printer when putting materials.

Glass and stretching glass.

This is cut and materials of one object are input to the 3D printer.

Pull handles with thick gloved hands ......

Objects were output under the part of the kiln.

Filaments are output through alumina · zircon silicic acid nozzles.

This is a straight line drawn ... ...

Because it is controlled by a computer, it is possible to overlap filaments in complicated form as follows.

It is the kore completed.

In addition to this, we create objects of various designs.

A design like "C" which was laid down sideways.

Torsioned one.

Design like a number of loops superimposed.

Things that can be used as a glass ... ...

Something that looks like the hem of a skirt that turns is also. Every one has a cool and beautiful appearance.

It is like an art work when it is displayed side by side.

When you hold the light over the top of the glass, a complex light pattern is drawn on the table.

I draw a pattern of light which can not be expected from the design of the glass.

This is a design officeMediated MatterWhenMIT Department of Mechanical Engineering, MIT'sGlass LabA project done by. It is a combination of the ancient technology of glass making and the latest technology, works from 2016Cooper-Hewitt National Design MuseumIt is scheduled to be exhibited at.

Related Posts: