Sneak into the LED factory as to how LEDs are made

ByJared Tarbell

Although the price is high compared with fluorescent lamps and incandescent light bulbs, LEDs that have advantages such as long lifetime, low power consumption and difficult to get hot are increasingly popular in recent years. Nate, who visited an LED factory located in China, shows how its LEDs are made in the factory that LEDs are being made at the factory.

How LEDs are Made - Learn.SFE

https://learn.sparkfun.com/tutorials/how-leds-are-made/all

A smiley, nice Si, will show us the LED factory in Shenzhen city this time.

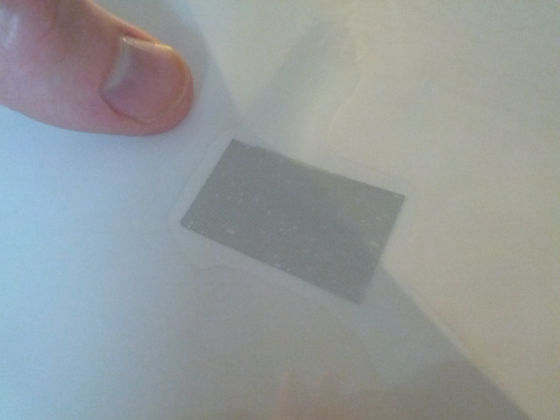

The image shown below is a sheet of LED die of approximately the same size as the thumb, which becomes the base of LED. This sheet contains 4000 chips and the price is about 12.5 dollars (about 1280 yen).

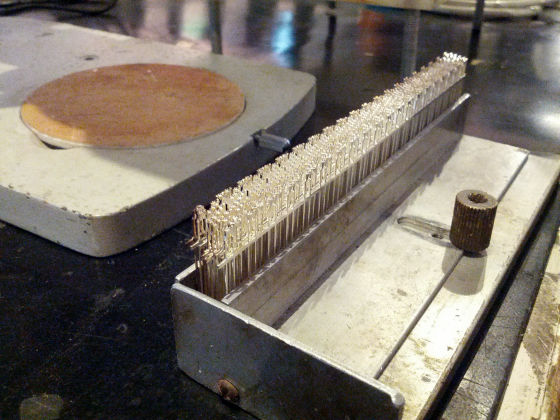

This is made of metalLead frameIt is said that it contains the basic structure of 20 LEDs per one.

A machine is indispensable for LED production. First of all, use this machine to drop a drop of sticky aqueous solution to the cathode terminal of the lead frame.

Next is to remove only the die from the LED die sheet and move it to the lead frame. Remove the die from a sheet containing as many as 4000 dies by hand while checking with the microscope.

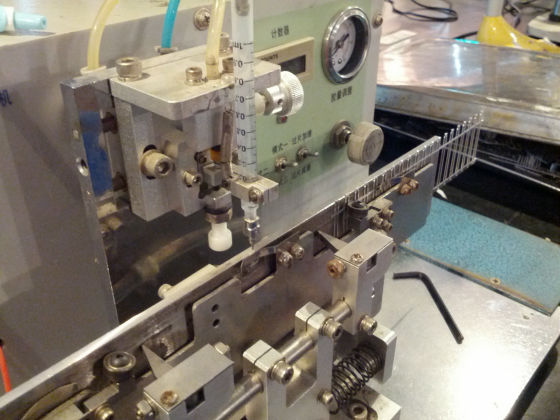

The following image is a machine which adheres the wire as thin as the hair on the lead anode at the top part of the LED die moved to the lead frame. Precise work will continue. .

After bonding the LED wire to the lead anode, put the LED in the mold and flush the epoxy resin.

The LED above the image below is in the mold.

This is a catalog of LED type. A special type of mold not included in the catalog is not impossible, but it is very difficult to obtain.

After pouring epoxy resin, it is heated for about 45 minutes. Then heat it again for about 8 to 12 hours to completely cure the epoxy. What is reflected in the image is already epoxy resin solidified.

Next, we test whether the created LED is using the proper amount of current. The machine of the image below checks the amount of current used by the LED and displays the result on the PC.

Cutting work to separate the cathode terminal from the lead frame is performed on the LED which clears the test.

Here is the red LED light completed through a long process.

The inside of the LED factory looks like this. The most surprising thing about Mr. Nate was that the work was done in a clean environment such as a clean room, rather than being done in any unusual space.

Related Posts: