Teijin Develops Aramid Fiber Blended with Tungsten Particles Shielding Radiation

ByN8 kowald

Radiation (X-ray, γ ray) shielding fibers blended with tungsten particlesTeijinDeveloped. Teijin has offered aramid fibers excellent in long-term heat resistance and flame retardancy to the field of life protection, but since the Great East Japan Earthquake, we are working on the development of radiation shielding materials, resulting in the result.

Teijin | News | About the development of aramid products shielding radiation

http://www.teijin.co.jp/news/2013/jbd130424_35.html

"Aramid" is a high-strength engineering plastic with high heat resistance, and it is used for hulls, airplanes, bulletproof vests, helmets, etc.KevlarAnd firefighting clothing etcNomexAnd the like are aramid fiberized. Among the aramid fibers, para type is high strength · high elasticity, meta type is heat resistant · chemical resistant.

In the Teijin Group, we deal with "Twaron" and "Technora" of para type aramid fiber and "Conex" meta type aramid fiber, but the radioactive shielded aramid fiber developed this time is made of tungsten It is made by blending particles. Tungsten is used because the lead known as radiation shielding material has regulatory trends worldwide due to environmental influences while tungsten has radiation shielding ability but low influence on human body and environment For.

Generally it is difficult to blend fibers with high specific gravity such as tungsten into fibers and spinning is difficult, and even when blended, strength and elastic modulus etc. may be impaired and it has not been put to practical use Although Teijin made use of Technora and Twaron's spinning method and physical properties peculiar to the material, it was able to reach realization.

In the case of "Technora", by making full use of the polymer technology and spinning technology cultivated so far, tungsten is uniformly compounded in the fiber.

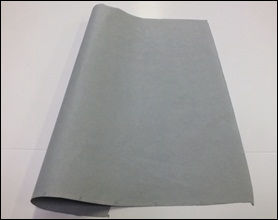

In the case of "Twaron", it is possible to have high adhesiveness with tungsten particles by making it into a pulp shape, and it is also possible to produce paper in which tungsten is evenly dispersed by combining with the sheeting technique about.

The finished product has strength superior to that of polyester while realizing radiation shielding ratio according to the amount of tungsten to be compounded, it is excellent in flexibility and processability as it is a woven fabric or paper and can not be realized with lead plate or concrete. Flexible It has the feature that it can be used in a shape.

We are planning to start offering samples for these products from the beginning of May and aim to deploy them in protective medical treatment and sheet material applications used in high radiation dose areas.

Related Posts:

in Note, Posted by logc_nt