Total construction cost 36 billion yen, manufacturing factory & installation observation report of optical submarine cable "SJC" with total length of 9000 km that can communicate at 23 Tbps

KDDI and Google (USA), Sing Tel (Singapore), Globe Telecom (Philippines), China Mobile (China), PT. Telekomunikasi (Indonesia), aiming to lay the optical submarine cable with a total extension of 9000 km connecting Japan and Singapore ) And other projects jointly conducted by 11 companies are "SJC(Southe-East Asia Japan Cable) ".

Conclusion of Construction and Maintenance Agreement for Optical Submarine Cable "SOUTH-EAST ASIA JAPAN CABLE SYSTEM" Between Japan and Singapore

http://www.kddi.com/corporate/news_release/2009/1210/index.html

※ As of November 2012, contents are partially different from those at the time of announcement in 2009

This time I went to the manufacturing factory of the cable which is the essential part of the project, the optical fiber cable was made and paid the whole story until it was loaded on the ship used to lower it to the seabed.

Ocean Cable & Communications Co., Ltd., which manufactures cables, has a submarine system office in the industrial area of Kitakyushu.

View Larger Map

I arrived at a factory located about 30 minutes by car from Kokura station on the gateway to Kyushu.

Signs.

Building is too big to be able to see the whole from nearby.

A road leading to the back of the site.

Arrived at the main entrance.

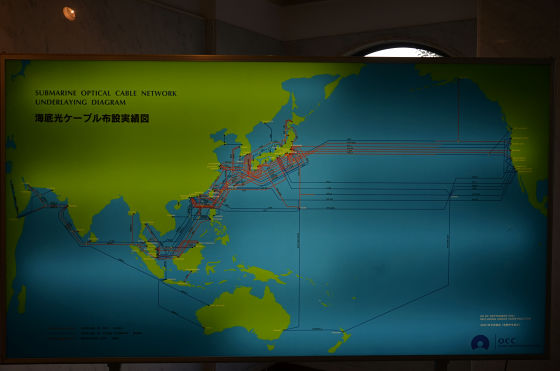

In the building there is a map depicting the place where the cable has been laid so far.

It is obvious that a tremendous number of cables are laid around Japan.

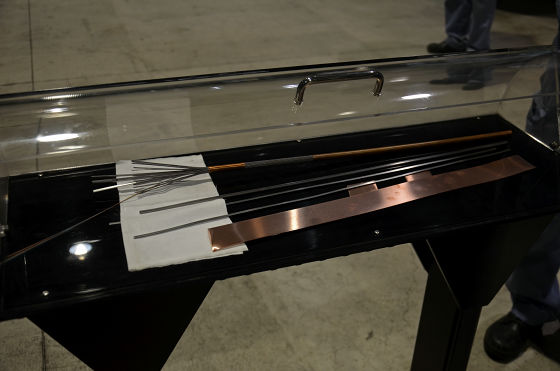

Cut the same cable as the one actually used and display what is easy to see inside is displayed.

◆ Outline of submarine cable business

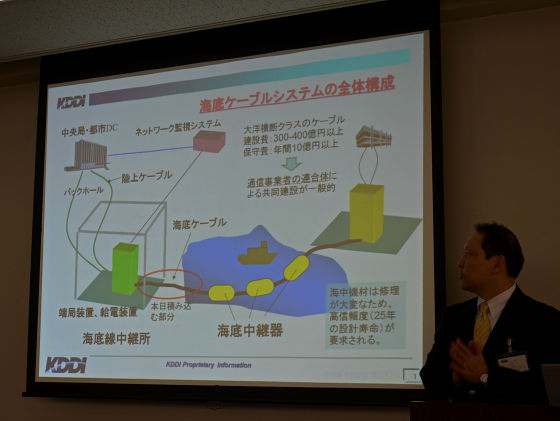

A presentation explaining the business outline started before the tour in the factory. According to KDDI 's first KDDI staff Hiroko Toba, the construction cost of the transoceanic cable costs 30 to 40 billion yen, and the maintenance cost will be more than 1 billion yen a year. For that reason, it is too heavy to cover all with one company, so usually,consortiumIt is said that the operation will be done by laying down and building.

In addition, as an outline of the whole facility, it is as shown in the following slide, the submarine cable is connected to the terminal equipment and the power supply equipment on the land, and the opposite side has the same equipment structure .

Since the product life of the cable is as long as about 25 years, in order to organize the consortium, it is necessary to carefully select the opponent by carefully examining the continuity of the business. Mr. Toba talked about the characteristics of the business with an easy-to-understand expression "I will spend a tremendous amount of Willikens for decades."

Next up was Mr. Masuda Akita of NEC who is doing equipment design etc. The company and its subsidiary OCC are manufacturing cables around Japan and branch cables to various parts of Asia in this project. Also, this submarine cable is buried at a depth of 1 to 3 m of the average seafloor and equipment is installed to prevent signal attenuation every 40 km to 100 km.

The market size of these submarine cable related businesses is 2.7 billion dollars, which seems to have a strong demand in Asia Pacific. Therefore, it is assumed that the line increase of 30% per annum is assumed, and it is said that it is a considerable growth market due to saying that another project to launch another cable may start around 2014.

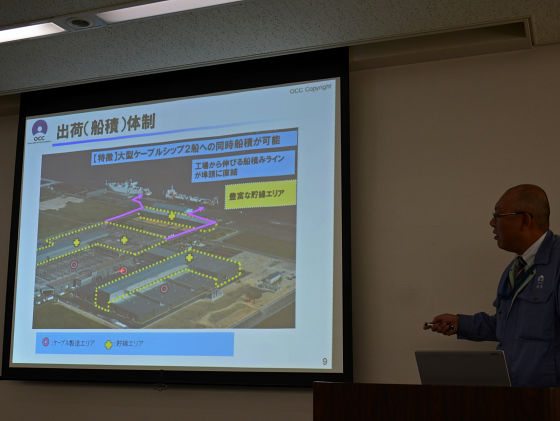

According to Mr. Hisatomi Sato who took the last stage, the company has a track record of submarine cable production of about 200,000 km and annual production capacity is about 20,000 km. The fact that there is a factory in Kitakyushu is that it is a place where you can barge a huge ship called a laying ship and the factory of Nippon Steel, the source of the main material, is nearby, the earth is stable and the earth is stable It seems that being a land pattern is a decisive factor.

After the presentation, we will ride a wagon and head inside the factory.

Cable manufacturing factory

Arrived in front of a huge building.

When entering inside, you will first see a sight that a roller that is more than twice the height of a person rotates with a gongulin. However, this part is "company secret" and shooting is impossible. It seems that the specifications of manufacturing equipment and proprietary know-how leak out to the outside seems to have a considerable sense of crisis, and photography was prohibited in many places besides here.

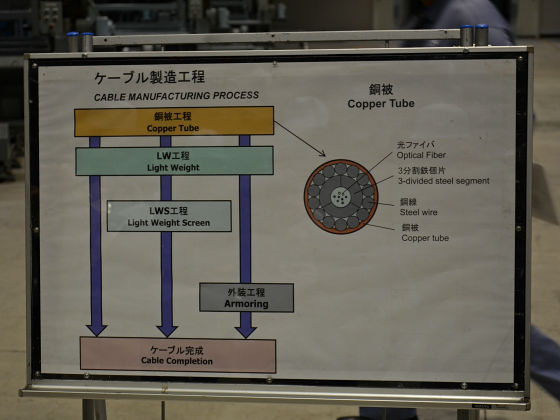

So, first of all, I took a panel showing the manufacturing process. Cables are classified according to the thickness of the exterior, and the initial process is common to all types. After that, it seems that we manufacture wires with increased strength by winding metal wires etc. as necessary.

In the early process, the operation of covering the optical fiber with a metal called "three-piece iron piece" has been carried out, and this part is the key to making a cable combining suppleness and strength.

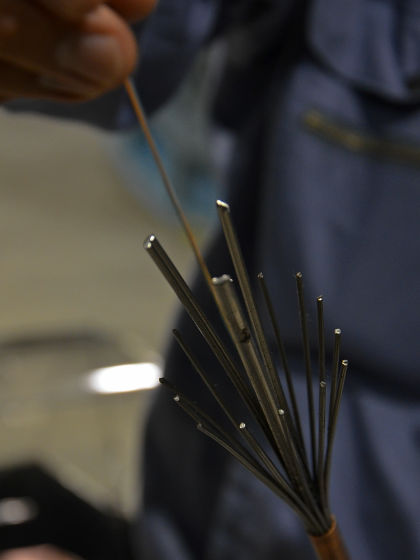

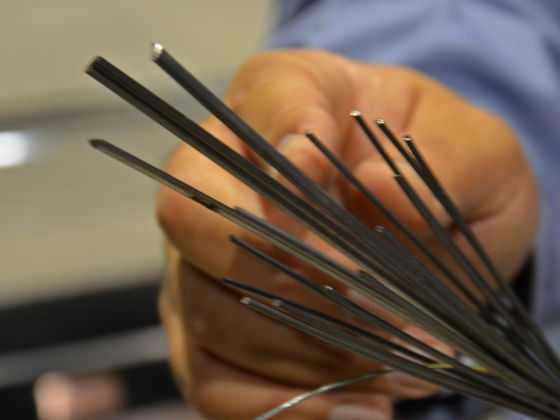

A man in blue clothing has a cable after having undergone the process being done in this place.

The colorful line that comes out from the center with Pyoron is an optical fiber, and this material itself can carry out communication at high speed, but at the same time it is fragile, so it is a translation that wraps a number of protective materials around it.

Three somewhat thick metal that jumps out in the middle is a "three-piece iron piece", and this part prevents damage by covering the optical fiber.

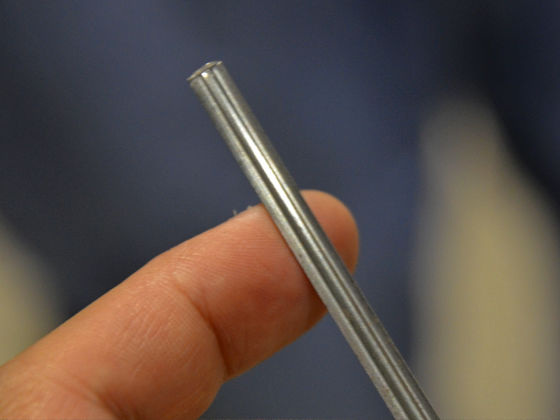

Taking one piece of "3 division iron pieces" in a hand is like this.

Furthermore, copper plate is wrapped around in the process after this, but photographing is also unnecessary for that part. When compared to hand-rolled sushi, it is work that involves the light fiber that is a piece and rice, and the three piece iron piece with a copper sheet that covers the seaweed, welding the copper plate while preventing the internal metal wire from being damaged The process of closing to the state is OCC's proprietary technology and can not be leaked to the outside.

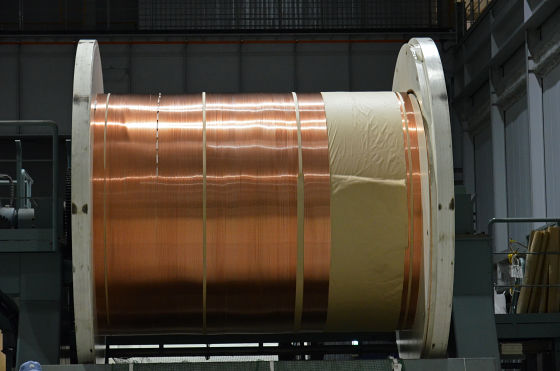

The cable that came out is wrapped around a huge roller like the following.

In addition, the cable which has undergone the process so far can continue to send a signal without breaking even if pulling with 10 ton force.

Roller before cable is wound.

The whole view of this area is as follows.

In the next process, the surface of the cable is coated with polyethylene for insulation and protection.

The exit of the cable that connects with the factory line we have just observed.

A cable hanging from the ceiling near the pillow.

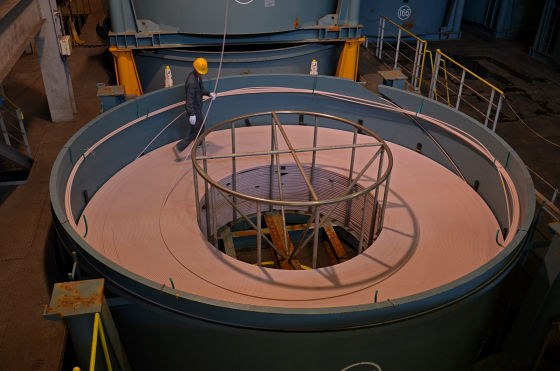

Finally, the cable is put in the tank with the hand of man.

In addition, this process can not be wound cleanly even if it is too late or too fast, it is necessary to judge the cables sent out one after another more quickly, so it seems to be a work that can only be done by a skilled expert is.

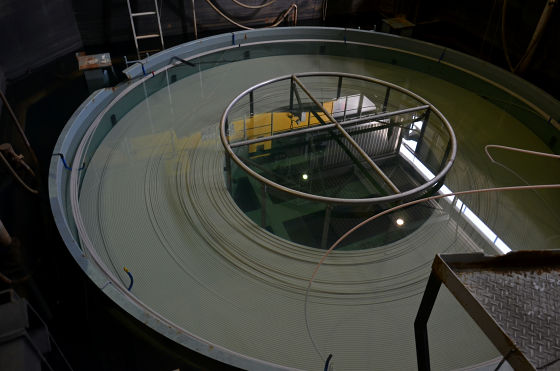

Once winding is finished, tests are performed to send the signal in water once it is immersed in water or to apply a voltage of 15,000 volts.

If there is no problem with the result of the test, move with the attached crane with each tank.

Cables that have undergone these steps have already been made usable and will be laid in this state in deep sea where there is little possibility of damage from the outside.

The cross section of the cable that passed through the process so far is as follows.

However, cables to be laid on the shallower seabed, which may be hooked on anchors and the like for fishery nets and ships, require excellent durability, so further protection cables are wrapped around them .

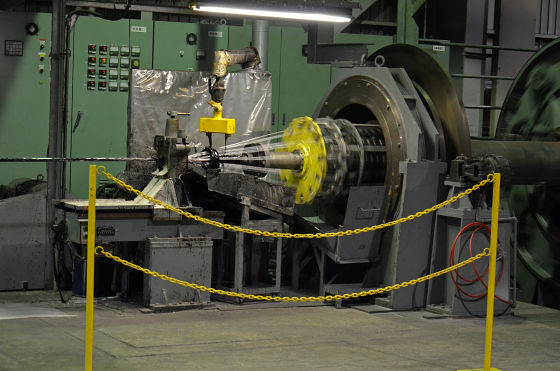

Cable to be rolled up with iron wire in a tremendous manner.

Since the work inside the factory is mostly mechanized, the main task of the staff is to monitor and inspect the machine, and the extent to which there are sparsely in the vast facilities.

A sample of the completed cable is as follows. The one on the left is the one with the strongest intensity, the one on the right is the state before winding the metal wire.

Trying to grasp the cross section looks like this.

In this way the cable around which the protective material is wound is put in the tank again and the inspection is carried out with the repeater which actually amplifies the signal connected, with the same length as when laid.

Amplifier collected in another room.

Looking up it is like this.

The cable that passed the final check will be loaded directly on the laying ship anchored immediately beside the factory.

The loading lines leading to the ship are as follows.

◆ Cable laying ship

Cable ship during loading operationKDDI Pacific Link".

Nyoronyoro and cables are being sent from the factory.

Cables being drawn into the ship

The cables that came into the ship are as follows.

It will be paid manually to the huge cable tank on the bottom of the ship.

The tank is 15 mm in diameter and 8 m in height.

Up to 2200 km of cable can be stored in one tank.

In addition, there is another similar tank in the ship and a compact tank so that you can store a total of approximately 4500 km of cable.

It is like this inside the ship where equipment called a cable engine that sends out cables toward the ocean is lined up.

Linear cable engine which feeds cables at high speed with rubber tires is mainly used for laying work.

Cables will come out of this area from this part.

Drum cable engines with holding capacity of more than 30 tons at low speed are mainly used for repair work etc.

Here I moved to the ship. When going out, the scenery of the industrial area by the seaside spreads in front of me.

The external appearance of the submarine cable burying machine "Cable Plow-II" outside the ship is as follows. Using this machine it is possible to fill the cable while cutting the groove to the bottom of the ocean.

Looking from the front like this.

It is connected with the control room on the shipUmbilical cable.

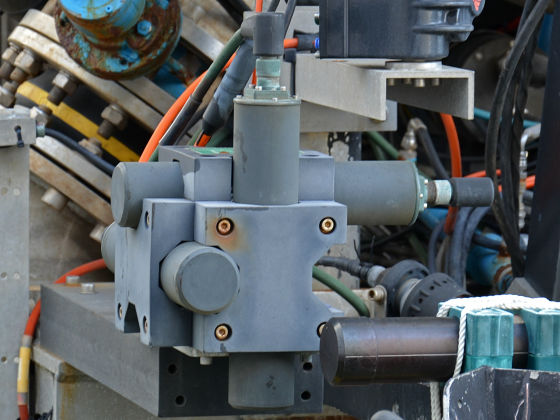

The appearance of a working robot "MARCAS-III" for laying cables while removing obstacles in the underwater is as follows.

A state of something being adjusted somehow.

Screw for propulsion.

Camera that captures the surrounding situation.

It is possible to remove obstacles using the robot arm and install equipment for cutting the cable at repair.

Also equipped with a sensor to detect the weak electric signal leaking from the cable to locate the position.

The laying ship sometimes works more than 40 days if it goes above the sea once, in that case it seems that the work will continue with the shift system. For that reason, basketball goals etc. are provided on board so that people who are not working can take a break.

The total construction cost of this project is about 36 billion yen (400 million dollars) and we will lay a cable with a total length of about 9000 km that connects directly to Japan and Singapore and branches to Hong Kong, Philippines, Indonesia etc, It is said that it aims to start operation. Immediately after completion, it is possible to communicate at 17 Tbps, and then capacity expansion can be done to 23 Tbps.

Related Posts: