Battery technology will be developed to realize ``electric vehicles that can run 1000 km on one charge''

A research team at Pohang University of Technology has developed a battery technology that uses silicon to improve energy density by 40%. The research team aims to realize ``an electric vehicle that can travel 1000 km on a single charge'' by innovating battery technology.

Formulating Electron Beam‐Induced Covalent Linkages for Stable and High‐Energy‐Density Silicon Microparticle Anode - Je - Advanced Science - Wiley Online Library

EVs that Go 1,000km on a Single Charge: Gel Makes It Possible » POSTECH

https://www.postech.ac.kr/eng/evs-that-go-1000km-on-a-single-charge-gel-makes-it-possible/

The cruising range of electric cars sold to the general public is only around 500 km, even if they are long. A cruising range of 500 km seems to be sufficient for daily driving, but when considering use for long-distance driving or as a power source in times of disaster, a longer cruising range is definitely advantageous.

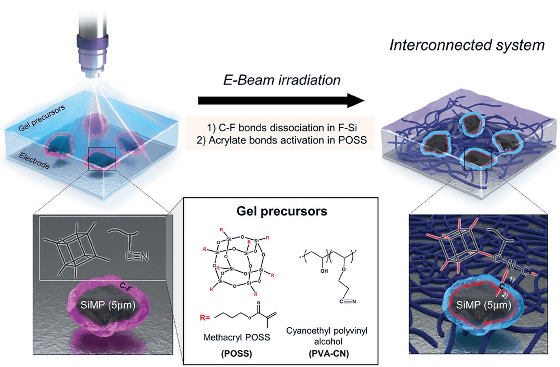

In order to extend the range of electric vehicles, it is necessary to improve the energy density of the lithium-ion batteries used as batteries. A promising approach to improving the energy density of lithium-ion batteries is to use silicon, which can hold a large amount of lithium ions, as the material for the negative electrode , but silicon has a tendency to increase in volume during charging. The problem is that it expands more than three times. The problem of silicon expansion can be solved by using nanometer-class silicon, but manufacturing nanometer-class silicon requires complex manufacturing processes and enormous costs, making it impractical.

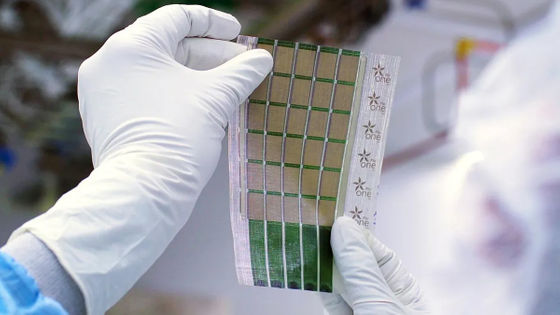

The research team created a 'silicon gel electrolyte' in which silicon gel and gel electrolyte are covalently bonded by encapsulating micrometer-class silicon in a gel electrolyte and irradiating it with an electron beam. By making a battery using this silicon gel electrolyte, they succeeded in creating a battery that has 40% higher energy density than conventional batteries while also suppressing the expansion characteristic of silicon.

The battery manufacturing technology developed in this research uses micrometer-class silicon, which is easier to manufacture than nanometer-class silicon, and can be applied to existing manufacturing processes in a short period of time. thing. The research team stated, ``With the results of this research, we have gotten closer to building a high-energy-density lithium-ion battery system,'' expressing their expectations for future research and development.

Related Posts: