The world's thinnest spaghetti, about 200 times thinner than a human hair, has been developed

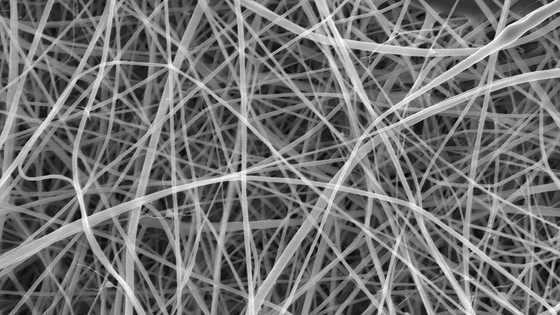

A research team at University College London has announced that they have developed the world's thinnest spaghetti, which is about 200 times thinner than a human hair. However, this spaghetti, which the research team calls ' nanopasta ,' was developed not as a food product but as a new fiber.

Nanopasta: electrospinning nanofibers of white flour - Nanoscale Advances (RSC Publishing)

Chemists create the world's thinnest spaghetti

https://phys.org/news/2024-11-chemists-world-thinnest-spaghetti.html

The research team pointed out that while starch nanofibers are attracting attention as a promising material in various fields such as biomaterials and environmental technology, the extraction and purification process consumes a large amount of energy, water resources, and chemicals that are environmentally harmful, which is a problem. Therefore, they were searching for nanofibers that could be produced in a way that has a low environmental impact.

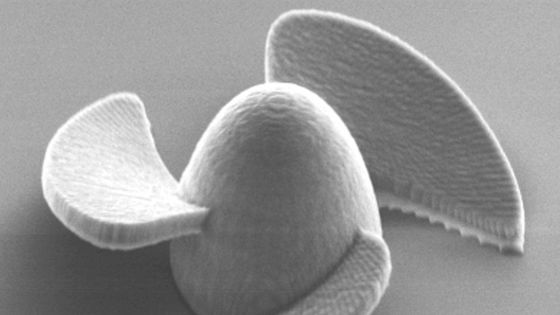

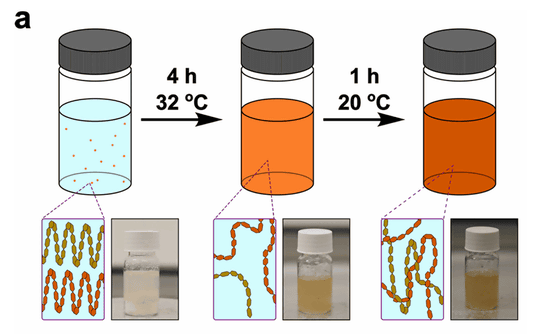

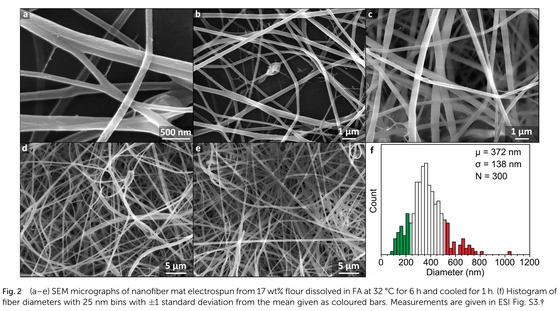

The research team dissolved 17 percent wheat flour by weight in formic acid heated to 32°C and heated it for four hours. During this process, the starch in the flour was dissolved and the hydroxyl groups of the starch were converted to formic acid esters. After cooling for one hour, they succeeded in creating a solution with a viscosity suitable for electrospinning . They were then able to produce 'nanopasta' with an average diameter of 372 nanometers from this solution.

Nanopasta has

Conventionally, the production of starch nanofibers required a large amount of water and electricity, as well as processing with multiple chemicals, but the method announced this time uses wheat flour directly, eliminating these processes, which means that it will lead to the establishment of a more environmentally friendly manufacturing method.

In addition, nanopasta is characterized by a simple and efficient manufacturing process. It was shown that nanofibers can be produced using only flour and formic acid, and in a relatively simple process that only requires controlling temperature and time. This could lead to reduced manufacturing costs and improved production efficiency.

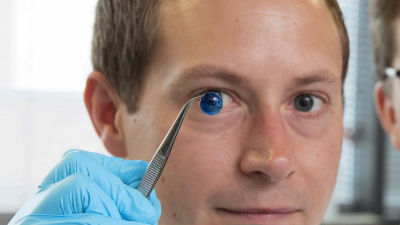

In addition, this material is biocompatible, biodegradable, and moderately hydrophilic, making it suitable for a wide range of applications, from medical materials for wound healing and drug delivery to environmental technologies such as filtration membranes and electrodes.

However, the research team cited several challenges, including instability during the spinning process, variations in fiber quality, the effects of non-uniform particle size of the raw material wheat flour, and clogging of equipment. In addition, process optimization and quality control are required for industrial-scale production. In addition, the safety and environmental impact of using formic acid must be evaluated and considered.

The research team believes that if they can find a solution to these problems, nanopasta could be further developed as a new, environmentally friendly nanomaterial.

Related Posts:

in Science, Posted by log1i_yk