How will 'computer vision', which analyzes with a camera and works by a computer, change the manufacturing industry in 2023?

' Computer vision ' is a research field that allows computers to understand digital images and videos and perform various processing, such as video analysis using cameras and 3D image processing using sensors. Voxel 51, a company that develops systems that incorporate computer vision, talks about cases where computer vision is applied in the manufacturing industry.

How Computer Vision Is Changing Manufacturing in 2023 - Voxel51

https://voxel51.com/blog/how-computer-vision-is-changing-manufacturing-in-2023/

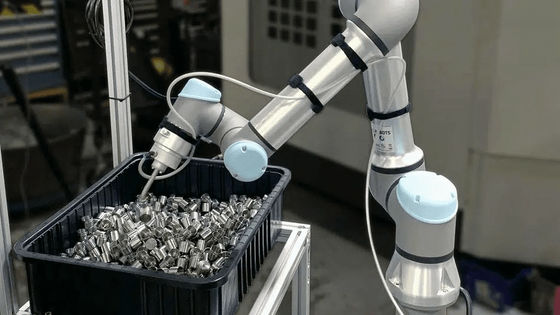

One of the tasks in which computer vision is applied to industrial robots is ' bin picking ', which selects and lifts objects from bins (parts storage areas) and places them in another location. You need to pass the camera image to an object detection routine for bin picking. Some computer vision systems use point clouds from LiDAR sensors, and it is possible to acquire in 3D where the object is placed and in what direction.

In addition, the work of industrial robots that requires computer vision is `` palletizing '', which stacks packages on pallets , and `` depalletizing ,'' which unloads packages stacked on pallets. A pallet is a flat base made of wood or metal on which goods are placed, and is indispensable in modern logistics. A pallet usually has a maximum load capacity of 1 ton and cannot be moved without the use of heavy machinery such as a forklift. However, with the advent of industrial robots, palletizing and depalletizing are being automated.

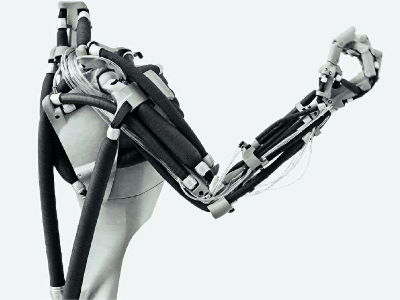

In order to perform palletizing and depalletizing, not only object detection but also calibration to move the robot arm to the correct position is important. When the robot arm loads or unloads an object, it feeds back the difference between the estimated position of the object and the actual position to refine future predictions.

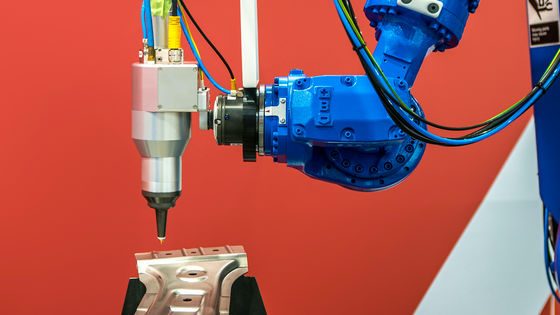

And ' machine tending ', which places parts on belt conveyors and machines for welding, grinding, milling, etc., is also becoming the work of industrial robots through computer vision. Automating machine tending has multiple benefits, including reduced risk of employee injury and increased consistency. Furthermore, it is now possible to maintain the machine with higher accuracy than before. Through real-time monitoring, the positional relationship between the machine and the input object is accurately grasped, and the robot arm adjusts its movements accordingly.

The availability and quality of data in machine tending has become a key issue. Computer vision systems for machine tending often need to be trained on limited labeled datasets. In other words, cleaning and curating the dataset used for training is essential, and data reinforcement and transfer learning are very important.

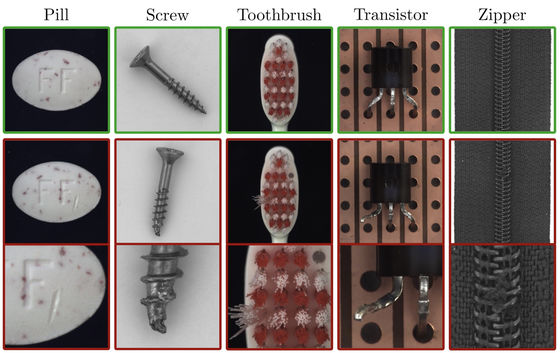

Furthermore, ' error product detection ' is also an area where computer vision functions. Until now, human eyes and hands have been used to check whether the manufactured parts are within the allowable range of the target size and whether the parts have small scratches or missing parts. , By detecting product anomalies with algorithms using density-based models such as DBSCAN and deep learning models, it is now possible to identify defective products as early as possible in the production line.

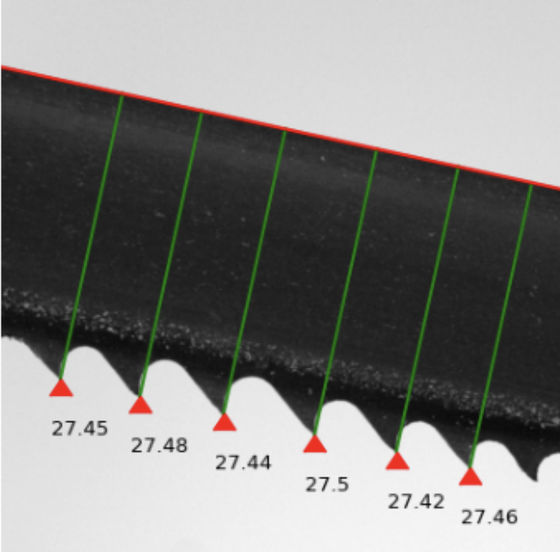

Computer vision is solving not only manufacturing line monitoring, but also ' predictive maintenance ' that monitors manufacturing factory tools and machines. Tools and machinery wear and tear over time, and lack of maintenance can lead to complete failure, resulting in employee injury and loss of productivity. Until now, each manufacturer has solved the problem by periodically checking the condition of the equipment and performing maintenance. However, predictive maintenance, which uses computer vision and algorithms to detect tool and machine failures, can prevent accidents while saving maintenance costs. For example, by periodically photographing and analyzing whether the saw blade used in the machine is worn out with a camera, it is possible to predict how much the blade is worn and when it should be replaced. is.

Voxel51 points out that the manufacturing industry is undergoing a major transformation that can be called the 4th Industrial Revolution, and that artificial intelligence, computer vision, robotics, and the Industrial Internet of Things (IIoT) are pushing the manufacturing industry forward. claims to be made by Voxel15 hopes that computer vision and robotics can solve this problem, as more than 2 million workers will be short in manufacturing in the United States by 2030.

Voxel51 added, ``Manufacturing, by its very nature, deals with almost every product we come across, such as screws, shoes, and cars. There is no one-size-fits-all solution because it is different for each,” he said, adding that the versatility of computer vision will enable more automation in industry and improve safety in manufacturing.

Related Posts: