A system to produce carbon-neutral jet fuel from sunlight, carbon dioxide, and water in a reactor 15 m above the ground will be developed.

In recent years, the idea of '

A solar tower fuel plant for the thermochemical production of kerosene from H2O and CO2: Joule

https://doi.org/10.1016/j.joule.2022.06.012

All-in-one solar-powered tower makes carbon-neutral jet fuel --ScienceDaily

https://www.sciencedaily.com/releases/2022/07/220720121020.htm

This'Solar Tower' System Produces Jet Fuel From CO2, Water, and Sunlight

https://singularityhub.com/2022/07/25/this-solar-tower-system-produces-jet-fuel-from-co2-water-and-sunlight/

All-in-one solar tower produces jet fuel from CO2, water and sunlight

https://newatlas.com/energy/solar-jet-fuel-tower/

In recent years, the automobile industry has been shifting from fossil fuels to batteries, but fossil fuels are still used in the aviation industry, which accounts for 5% of the world's greenhouse gas emissions, and the development of clean aviation technology. Deployment still takes time. Therefore, the aviation industry is paying attention to 'carbon-neutral jet fuel' that totally offsets carbon dioxide emissions. Carbon-neutral fuel burns in the engine and emits carbon dioxide like ordinary fossil fuel, but since it takes in carbon dioxide in the environment during the manufacturing process, it is possible to reduce carbon dioxide emissions in total. increase.

As carbon-neutral fuels, bio-jet fuels that use biomass raw materials such as wood-based cellulose are attracting attention, but these fuels require land for cultivating plants and carbon dioxide for fertilizers and agricultural machinery. There is also the problem of discharging. In addition, the method of synthesizing fuel from landfill waste and waste oil also uses a lot of energy in the manufacturing process, so the problem of carbon dioxide emissions will remain in the end.

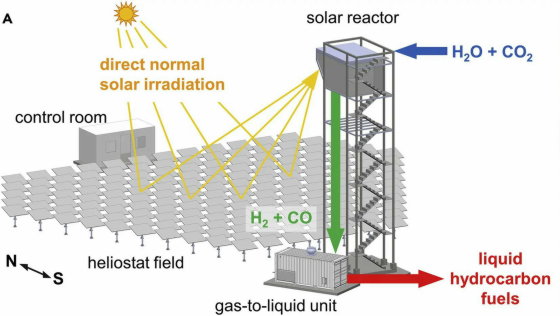

Therefore, a research team led by Professor Aldo Steinfeld of the Department of Mechanical Process Engineering, ETH Zurich, has developed a system for producing carbon-neutral jet fuel using sunlight, carbon dioxide, and water. This is what the research team actually built to conduct a system demonstration experiment. Building in the center is a tower-type solar reactor that manufactures jet fuel.

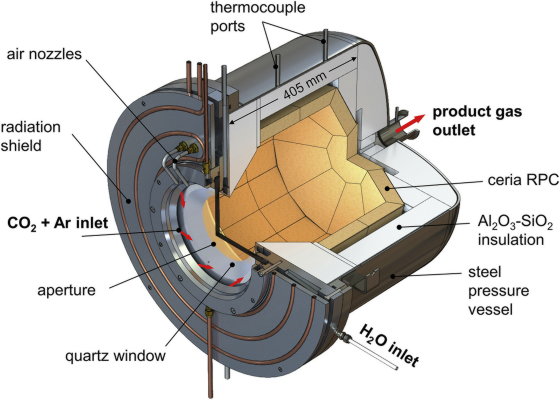

The system collects the sunlight reflected by 169 solar-tracking reflectors lined up around it into a hole just 16 cm in diameter in a solar reactor at a height of 15 m. The enormous amount of heat energy collected by a large number of reflectors is used to cause a

The inside of the reactor looks like this. The converged solar energy, along with the porous structure of

The syngas produced is supplied to the Gas-to-Liquid unit at the bottom of the tower, with a liquid phase containing 16% synthetic kerosene and 40% synthetic diesel, and 7% synthetic. It is converted into an oil layer consisting of kerosene and 40% synthetic diesel. Since the carbon contained in these liquid hydrocarbon fuels is derived from carbon dioxide extracted from the air, even if it is burned as jet fuel, the total carbon emissions can be offset.

The research team actually operated the tower reactor for nine days and experimented with how much fuel it could produce. In this experiment, if the weather was good, 6 to 8 cycles were performed a day, and each cycle lasted an average of 53 minutes, with a total operating time of 55 hours.

The tower reactor was reported to eventually produce a total of 5191 liters of syngas in nine days of operation, but it is unclear how much synthetic kerosene and diesel was ultimately refined. The Boeing 787 has a maximum fuel capacity of 126,372 liters and can fly a distance of 14,140 km from New York, USA to Ho Chi Minh, Vietnam. Given this, you may feel that one solar reactor can produce too little fuel, but synthetic fuels can be mixed with regular fuels, so you don't have to replace all the fuels. Even if the synthetic fuel produced by the reactor cannot replace all jet fuels, the amount produced will lead to a reduction in overall carbon dioxide emissions.

In this experiment, the energy conversion efficiency from solar energy to synthetic gas was only 4%, but the research team recovered and recycled more heat and reviewed the structure of cerium oxide (IV) to improve efficiency. I think it can be increased to 20% or more. 'For the first time, we have demonstrated the entire thermochemical process chain from water and carbon dioxide to kerosene with a fully integrated solar tower system. This solar tower fuel plant is ready for industry deployment. It operates in the right settings and sets a technological milestone for sustainable aviation fuel production. '

Related Posts:

in Science, Posted by log1h_ik