According to a survey that the median semiconductor inventory of companies is less than 5 days, the semiconductor shortage is expected to be resolved in the latter half of 2022 at the earliest.

In response to the

Results from Semiconductor Supply Chain Request for Information | US Department of Commerce

https://www.commerce.gov/news/blog/2022/01/results-semiconductor-supply-chain-request-information

Secretary Raimondo Announces Results of Request for Information on Semiconductor Supply Chain | US Department of Commerce

https://www.commerce.gov/news/blog/2022/01/secretary-raimondo-announces-results-request-information-semiconductor-supply

Chip Shortage Means Some Companies Have Less Than 5 Days Worth of Inventory | PCMag

https://www.pcmag.com/news/chip-shortage-means-some-companies-have-less-than-5-days-worth-of-inventory

The pandemic of the new coronavirus infection (COVID-19) has driven some major semiconductor factories out of service, disrupting the supply chain, as well as expanding remote work and learning, and changing lifestyles. Increased demand for semiconductors such as PCs and game consoles. Private companies have dealt with semiconductor shortages, but demand continues to outpace supply, negatively impacting a wide variety of areas such as PCs, smartphones, game consoles, automobiles and medical devices.

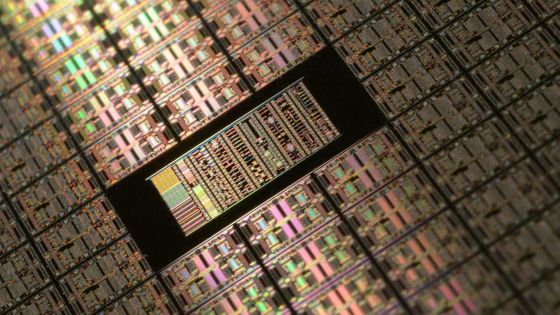

To gain insight into the semiconductor supply chain, the US Department of Commerce conducted an interview survey on the semiconductor supply chain in September 2021 targeting major semiconductor manufacturers and manufacturers of consumer products that use semiconductors. The US Department of Commerce, which received responses from more than 150 companies in total, published the survey results on January 25, 2022.

The main findings reported by the US Department of Commerce are:

・ While the median demand for semiconductors by each manufacturer increased by 17% from 2019 to 2021, suppliers have not been able to increase their supply in response to the increase in demand.

・ The median semiconductor inventory held by each manufacturer was about 40 days in 2019, but has fallen to less than 5 days in 2021.

-The main bottleneck that causes semiconductor shortages is the semiconductor production capacity of factories.

・ The responding companies do not expect the semiconductor shortage to be resolved in the next 6 months.

The U.S. Department of Commerce said in response to a survey that 'the median semiconductor inventory of a company is less than 5 days', 'This is the case when there is a possibility that a semiconductor factory will be closed for 2 to 3 weeks overseas. It means that a manufacturing facility with only 3-5 days of inventory will no longer be operational and workers will be out of work. '

It has also become clear that semiconductor shortages are not equally occurring in all industries, but are particularly concentrated in some industries. According to the U.S. Department of Commerce, supply and demand are particularly high in legacy logic chips used in medical equipment and automobiles, analog chips used in power management equipment and image sensors, and

The US Department of Commerce has pointed out that the bottleneck in a series of semiconductor shortages is the production capacity of semiconductor factories. Since the second quarter of 2020, the utilization rate of semiconductor factories has always been 90% or more, which is significantly higher than the previous level.

Responding companies believe that the semiconductor shortage will not be resolved for at least the next six months, but semiconductor manufacturers are focusing on increasing production capacity. Intel plans to invest more than 2 trillion yen to build a semiconductor factory in Europe, and also plans to build a semiconductor factory in Ohio, USA, and GlobalFoundries, a major American semiconductor maker, will also open a new factory in New York. Announced to build. Some factories will start operations in the latter half of 2022 at the earliest, so there is a possibility that some of the semiconductor shortages will be resolved.

Based on the results of this survey, the U.S. Department of Commerce will pass the 'US Innovation and Competition Law ,' which includes an investment of 52 billion dollars (about 5.9 trillion yen) in the domestic semiconductor industry in order to increase domestic semiconductor production. Claims that it is necessary. Secretary of Commerce Gina Raimondo said, 'If we do our best, we'll be further behind. But if we pass this bill and deal with the problem, it will create good jobs for decades to come and the United States You can rebuild your manufacturing industry and strengthen your country's supply chain. '

Related Posts:

in Hardware, Posted by log1h_ik