Find a hint to the mystery of 'the extraordinary durability of Roman concrete' from a tomb built 2050 years ago

by

The concrete used in many buildings has a lifespan of about 50 to 100 years, but Roman concrete made during the Roman Empire has been strong for nearly 2000 years. To approach the mystery 'Why Roman concrete is stronger than modern concrete?', Research teams at the Massachusetts Institute of Technology (MIT) and Utah University said, 'Roman concrete made 2050 years ago. We are analyzing 'a huge tomb'.

Reactive binder and aggregate interfacial zones in the mortar of Tomb of Caecilia Metella concrete, 1C BCE, Rome --Seymour ---- Journal of the American Ceramic Society --Wiley Online Library

https://ceramics.onlinelibrary.wiley.com/doi/10.1111/jace.18133

2,050-year-old Roman tomb offers insights on ancient concrete resilience | MIT News | Massachusetts Institute of Technology

https://news.mit.edu/2021/roman-tomb-offers-insights-ancient-concrete-resilience-1008

Various Roman relics are preserved in Italy's Appia Highway State Park. One of the best-preserved buildings is the tomb of Caecilia Metella , the wife of Marcus Licinius Crassus , who had a triumvirate with Gaius Julius Caesar and others.

The tomb of Caecilia Metella is a huge structure built on a square base and is said to be 20m high and 29m in diameter. Although it seems to have been built around 30 BC, it remains as it is until the present day, and it was also used as a military base in the Middle Ages. The image below shows how magnificent the tomb of Caecilia Metella is. 'Concrete tissue remains strong and resilient even after 2050,' said Marie Jackson, a member of the research team and a geology and geophysics researcher at the University of Utah.

by

The tomb of Cecilla Metella is an example of sophisticated concrete construction techniques in the late Roman Republic. Roman architect is Vitruvius for the preparation of the time concrete, such as the rough brick and volcanic rock aggregate made of lime and volcanic tephra (shards of glass crystal and porous that is released by the eruption) mortar bound in If you make a thick wall, it will not be ruined even after a long time.

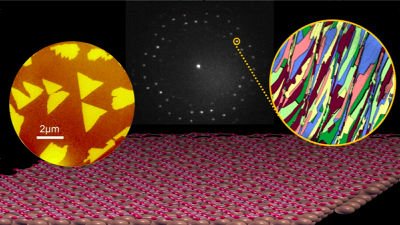

Vitruvian's words are supported by several Roman structures, such as the Roman concrete Trajan's market and marine structures such as breakwaters. The research team investigated the microstructure of the concrete used for the tomb of Caecilia Metella with a scanning electron microscope , and the constituent elements and concentrations with energy dispersive X-ray analysis.

Analysis shows that the concrete used for the tomb of Caecilia metella is a mortar containing volcanic tephra that combines brick and volcanic rock aggregate, and the mortar is similar to that used in the Trajan's market. understood. However, while the mortars on the market for Trayanus are composed of a component called calcium silicate hydrate (CASH-bonded phase) and mineral crystals called strätlingite, the mortar used for the tomb of Caecilia metella There was almost no stratringite.

The mortar of Caecilia's tomb is rich in leucite , a silicate mineral mainly composed of potassium and aluminum, and rainwater and groundwater have permeated the walls of the tomb for centuries. As a result, the potassium of leucite dissolved in the mortar. In modern concrete, if potassium is too abundant, expansive gel will be formed and cause fine cracks, but in the tomb of Caecilia metella, potassium was dissolved and the CASH bond phase was reconstructed. The research team says this process strengthens the concrete bond and makes it more durable.

by Allie_Caulfield

'The interface between aggregate and mortar in concrete is the basis of structural durability. In modern concrete, the alkali that forms the expansive gel,' said Admir Masic, an associate professor of civil and environmental engineering at MIT. Aggregate reactions can damage the interface, even in the hardest concrete. ' 'It was found that the concrete interface areas of ancient Rome in the tomb of Cecilla Metella are constantly evolving due to long-term reconstruction. These reconstruction processes strengthen the interface area and improve mechanical performance. And may contribute to the durability of old materials. '

Related Posts:

in Science, Posted by log1h_ik