NASA is releasing a time-lapse movie that tracks the two-year manufacturing process of the next-generation supersonic aircraft 'X-59'

NASA has released a time-lapse movie that takes two years to assemble the silent supersonic aircraft 'X-59 ', which is being developed as one of the experimental aircraft and rocket '

X-59 Resembles Actual Aircraft | NASA

https://www.nasa.gov/feature/x-59-resembles-actual-aircraft

NASA began developing the X-59 in 2018. Lockheed Martin , an aircraft and spacecraft developer, has signed a contract with NASA to manufacture the X-59 for $ 247.5 million by 2022.

NASA announces that it has started development of a supersonic aircraft 'X-Plane' that does not generate a sonic boom --GIGAZINE

The X-59 is under construction at Lockheed Martin's assembly plant in California. It is designed to fly over the surface of the sea at supersonic speeds of about 660 mph (about 1062 km) without causing a sonic boom.

You can see how the X-59 is actually assembled in about two years from May 2019 to June 2021 in the following time-lapse movie.

Time-lapse of X-59 Quiet SuperSonic Technology aircraft (May 2019 --June 2021) --YouTube

https://www.youtube.com/watch?v=LcvYjkCBY28

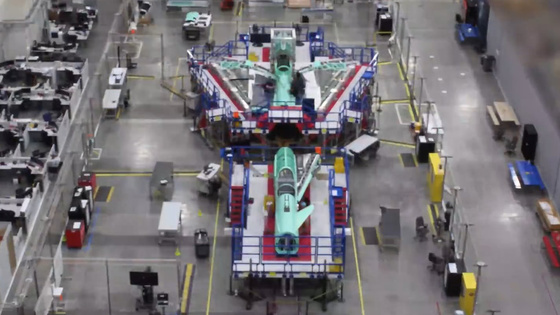

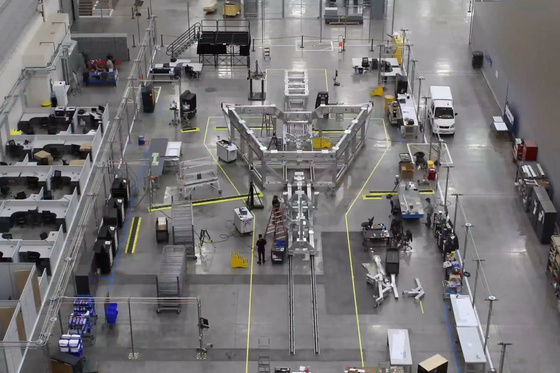

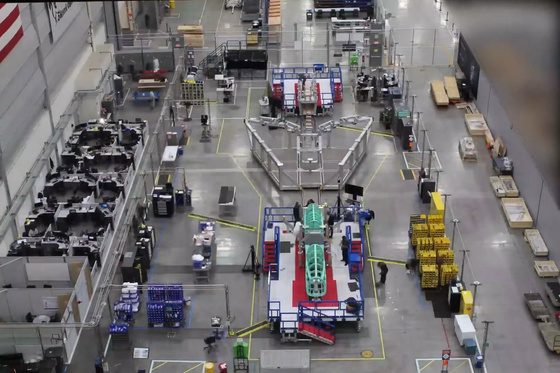

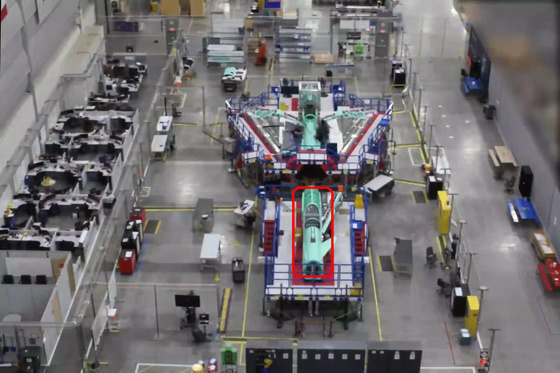

The X-59 is an aircraft with delta wings , similar to the supersonic aircraft Concorde , which was once operated for commercial purposes. Frames for assembly are lined up in the factory.

The elongated part below is the fuselage part of the fuselage, which is 30 feet (about 9.1 m) long, and the flow is that the wings are assembled and then connected. Two cameras are attached to the nose of the X-59, and the images captured by these cameras are processed by a computer and displayed on a 4K resolution monitor in the cockpit. NASA calls this system the '

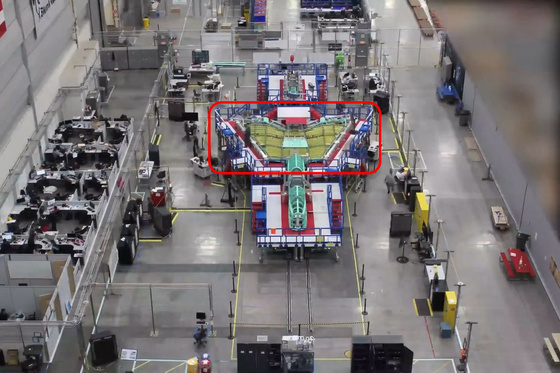

And the moment when the assembled fuselage and wings are combined. The fuel mechanism and control mechanism are housed in the wing, which is 29.5 feet wide (about 9.0 m), and it has the most complicated structure. The wing part is the first part to be manufactured, and it is said that it was assembled by two robot machines named 'Mongoose' and 'Cobra' respectively.

I can see the shape of the body part, which was only the skeleton. The shape of the nose is finally designed to suppress the occurrence of sonic booms and prevent noise problems.

The tail wing is assembled on the wing.

The X-59 is under construction and will be tested for initial flight in 2022, according to Dave Richwine, deputy project manager for NASA's low-shock wave flight demonstrations and ration (LBFD) technology. It is said that it has become. In 2023, it will fly at the Armstrong Flight Research Center test site in California to prove that it is actually noise-free and can be safely operated in national airspace. In 2024, we plan to actually fly the X-59 over multiple parts of the United States to see if people on the ground can hear the sonic boom 'Don!'.

The X-59 is a single-seater fighter, not intended for supersonic flight with passengers like the Concorde. 'If NASA's X-plane development plan collects data on supersonic flight, aircraft manufacturers will develop new supersonic aircraft in the future, and private airlines will prepare supersonic flights. You may be able to do it. '

Related Posts: