What is happening in the 'new corona vaccine supply chain'?

Software developer

Exploring the Supply Chain of the Pfizer / BioNTech and Moderna COVID-19 vaccines · Neubertify

https://blog.jonasneubert.com/2021/01/10/exploring-the-supply-chain-of-the-pfizer-biontech-and-moderna-covid-19-vaccines/

◆ Vaccine ingredients

Before we think about our supply chain, we need to know what makes up a vaccine. Pfizer and BioNTech's ' BNT162b2 ' and Moderna's ' mRNA-1273 ', which have started vaccination at the time of writing, all have information on vaccine composition on Wikipedia. The main ingredients are as follows.

・ MRNA

The new coronavirus vaccines approved at the time of writing the article are all mRNA vaccines that use mRNA with nucleotide sequence information. mRNA plays a major role in the acquisition of immunity of the new coronavirus by the human body, and components other than mRNA can be said to be necessary additives for introducing the vaccine into human cells.

・ Lipid

The two vaccines contain lipids such as cholesterol , phosphatidylcholine , ionizablecationic lipids , and PEG-modifiedphospholipids , which form capsules around the mRNA called lipid nanoparticles . Lipid nanoparticles protect mRNA from the surrounding environment and immune system until it enters the human cell, bind to mRNA to stabilize its state, and release mRNA in the cell in a timely manner. That thing.

・ Buffer (buffer solution)

Vaccine hydrogen ion exponent (pH) for the active ingredient when is too high or too low is likely to be destroyed, it is important to control the pH level of the vaccine. Therefore, 'BNT162b2' uses phosphate buffered saline , and 'mRNA-1273' uses a buffer solution that combines trishydroxymethylaminomethane (tromethamine) , tromethamine hydrochloride, sodium acetate , acetic acid, etc. to control the pH of the vaccine. I am.

・ Sucrose

Sucrose is a sugar molecule made from sugar cane etc., and it is said that it is used to damage other components during frozen storage, and it is the largest component other than water in the total weight of the vaccine. ..

◆ Manufacturing process

Pfizer, BioNTech, and Moderna all have independent supply chains in Europe and the United States. This is said to be useful for increasing the production capacity of vaccines, ensuring redundancy, and increasing restoring force. It takes about a few weeks from the first process to the completion of the vaccine manufacturing process. The main manufacturing process is as follows.

・ DNA production

In order to produce mRNA, it is necessary to first produce DNA , and Pfizer produces DNA at a facility in St. Louis , Missouri, USA. On the other hand, Moderna has outsourced DNA to Lonza , a Swiss biotechnology company, and Lonza is also producing mRNA, which is the subsequent process. Lonza's factories that produce DNA and mRNA are said to be in Portsmouth , New Hampshire, USA and Visp , Switzerland.

・ MRNA production

In the case of Pfizer, the DNA produced in St. Louis is shipped to the BioNTech facility in Andover, Massachusetts or Germany, where it is converted to mRNA in a bioreactor . This is the first time that an mRNA-based vaccine has been approved, and since no such large amount of mRNA has been produced in the past, it is considered to be the highest risk in the supply chain. It is said that it is the production process of mRNA.

・ Lipid production

Pfizer uses lipid components produced by Croda 's subsidiary in Alabaster , Alabama, USA. On the other hand, Moderna procures lipids from Corden Pharma, which is headquartered in Germany, and Corden Pharma has production bases in Colorado, Switzerland, and France in the United States.

・ Production of lipid nanoparticles

The production of lipid nanoparticles is said to be one of the major bottlenecks in the production of mRNA vaccines, as few people know how to combine lipids and mRNA to produce lipid nanoparticles. Pfizer is working with a company called Acuitas Therapeutics in Vancouver, Canada to produce lipid nanoparticles, and Moderna is believed to have outsourced the process to Lonza.

・ Filling and finishing

The remaining step in the production of a vaccine is the process of blending lipid nanoparticles and buffers containing mRNA, and sucrose into a small bottle called a vial. Pfizer of America Michigan Kalamazoo a vial of the United States for at, of Belgium Pools addition that makes the vial for Europe, that of the BioNTech have domestic facilities to cope with the German demand. Moderna is of the United States Catalent of and Spain Laboratorios Farmacéuticos Rovi signed an outsourcing contract, is that of to have engaged in the manufacture of the vial.

・ Packaging

Vials are packaged in easy-to-use units before shipping. Each Pfizer vial contains 5 doses of vaccine, and 195 vials are included in one set, so one set can be inoculated a total of 975 doses. Each Vial of Moderna contains 10 doses of vaccine, 10 pieces are put together in 1 carton, 12 cartons are shipped in 1 case, and 1200 times can be inoculated in 1 case. I am.

◆ Vaccine transportation and equipment supply

Vaccines packaged at production facilities are shipped worldwide, but which facility they are shipped from depends on the final vaccination site. Both vaccines are produced in the United States and Europe, and at the time of writing the article, the production facility and the inoculation point are relatively close, but as the inoculation starts in more countries, the supply chain will further diverge. It is expected to go. The main topics related to transportation and actual vaccination are as follows.

・ Temperature requirements

Pfizer and BioNTech vaccines need to be stored and transported at an ultra-low temperature of '-60 to -80 degrees' and Moderna vaccines to '-15 to -25 degrees', so luggage can be transported at low temperatures. Maintenance of the cold chain is important. It is said that medical institutions that inoculate can store the vaccine in the refrigerator for up to 5 days, but the procurement of ultra-low temperature freezers, delivery boxes, temperature trackers, etc. may hinder the distribution of vaccines, especially in developing countries. There is. In the United States, pharmacists have been arrested for 'intentionally leaving the vaccine at room temperature to deteriorate it.'

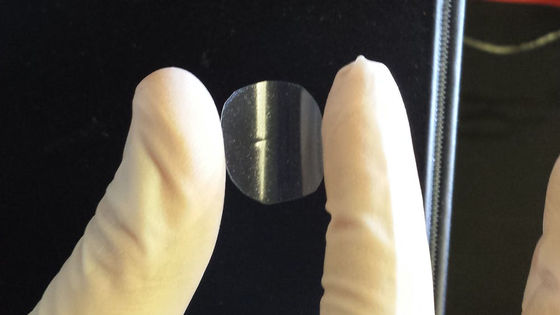

・ Glass vial

Vaccine vials cannot be made of ordinary glass because they must withstand physical shock and freezing at minus tens of degrees. The best material for vaccine vials is borosilicate glass , but the source borate is from a limited source, with three-quarters of the total supply coming from Turkey and most of the rest coming from the United States. And that. In addition, few manufacturers manufacture borosilicate glass for vaccine vials, and it seems that the lack of vials is one of the reasons why one vial is filled with several vaccines.

・ Other equipment

Vaccination requires more than just the vaccine itself and vials. A syringe and needle, a disinfectant wipe to clean the injection site, gloves are required, and the Pfizer and BioNTech vaccines require a procedure of diluting with 20 mL saline immediately before use. Since vaccination cannot be done without supplying these equipment to medical institutions, it is said that supplies are being supplied in the United States through a public-private partnership called ' Operation Warp Speed '. In addition, distribution of explanatory materials for patients and healthcare professionals, establishment of a call center for inquiries, countermeasures against counterfeit vaccines, etc. are also important for safe and reliable vaccination.

Related Posts:

in Science, Posted by log1h_ik