Facebook develops 'robot capable of overwhelmingly and efficiently laying optical fiber cables'

Facebook announces a robot specializing in laying fiber optic cables. By using this robot and a newly developed optical fiber cable, it is possible to greatly reduce the cost of laying an optical fiber network so far, and it will be possible to provide a cheaper and faster internet infrastructure to a wider range is.

Aerial fiber deployment, faster and more efficient-Facebook Engineering

You can see what kind of robot the fiber optic cable laying robot developed by Facebook is like by watching the following movie.

Making aerial fiber deployment faster and more efficient-Facebook Engineering

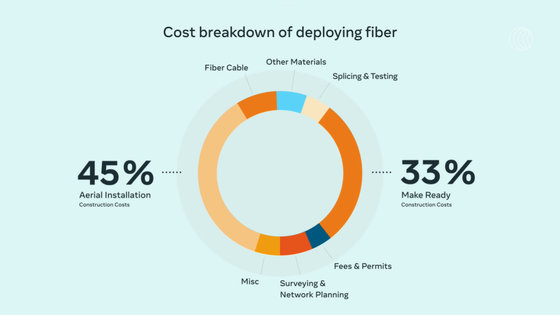

Even with the increase in communication bandwidth and the demand for faster Internet networks, the introduction of optical fibers has not progressed slowly in some regions. The reason is the cost of laying optical fiber. Nearly 80% of the cost of introducing optical fibers is due to the laying of optical fiber cables.

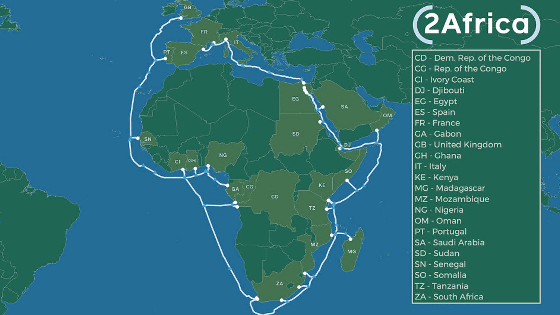

There are two locations for laying fiber optic cables: underground and aerial. However, according to Facebook, about half of the world's daily income is less than $5.5 (about 590 yen), so laying in the underground, which is very costly, is not realistic. Then, Facebook paid attention to the electric wires that were laid all over the air.

For example,

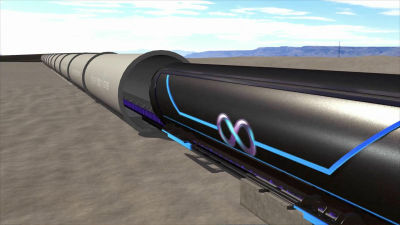

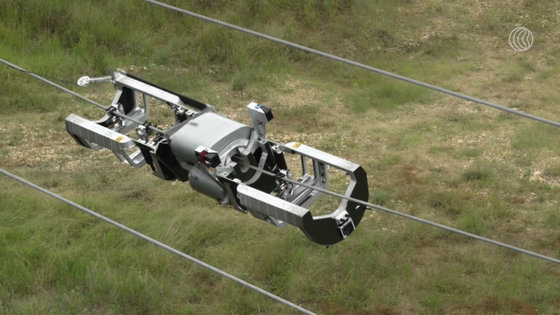

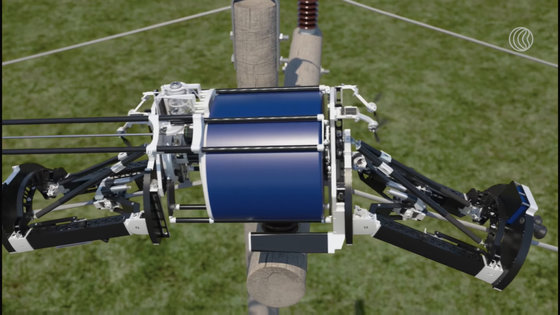

Laying a fiber optic cable along a medium piezo wire requires a large number of personnel. Therefore, Facebook has developed a robot for laying optical fiber cables using this medium piezoelectric wire network.

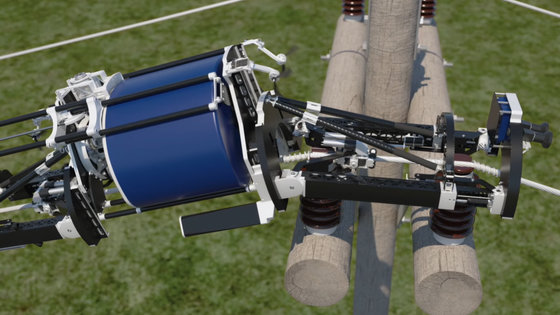

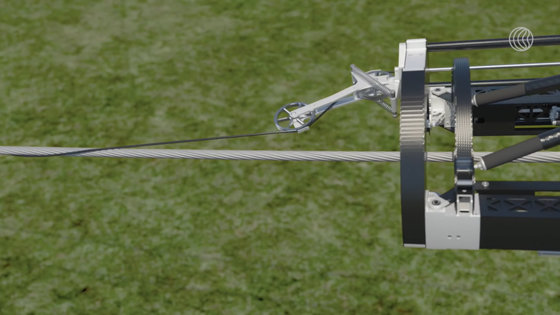

A robot clinging to a medium piezoelectric wire

The robot lays the optical fiber cable while moving along the medium piezoelectric wire.

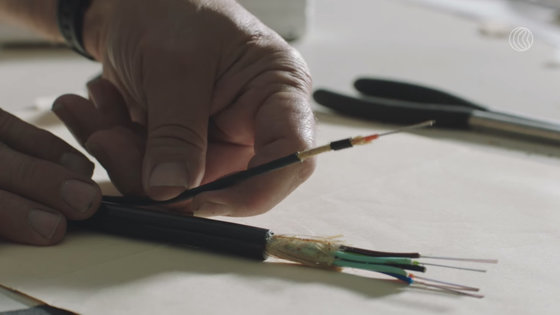

For this project, Facebook is developing a new fiber optic cable that can withstand the heat and environmental stresses of medium piezo wires.

Of the following, the upper cable is the newly developed one and the lower one is the conventional cable. You can see that the new optical fiber is much thinner than the old one. Of course, the thicker the number of optical fibers included, the larger the communication bandwidth, but Facebook says that 'one fiber is enough unless it is a city where the population is concentrated.'

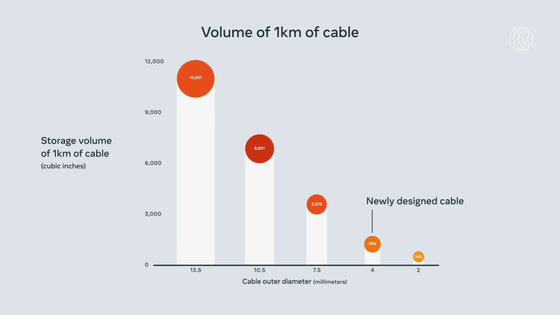

The thicker the cable, the larger the total volume of the cable, the heavier the weight, the more the load on the wires, and the higher the production cost. In other words, Facebook has developed a thin cable in order to significantly reduce the installation cost.

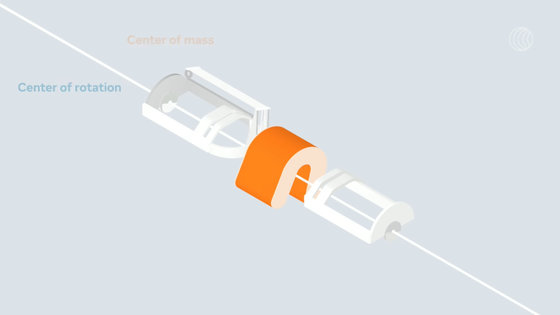

The robot is mainly divided into 3 parts, 'driving part', 'rotating part' and 'rotation assisting part'. The white driving part clings to the cable and advances the robot body forward. The central orange rotating part is loaded with optical fiber and sends out the cable while rotating.

The cable discharged from the rear rotation assisting part is wound around the medium piezoelectric wire.

In addition, the robot is equipped with joints, and it is said that the electric pole, which is a relay point for the medium piezoelectric wire, will bend and bend over the body while maintaining balance with the stabilizer.

A full-scale technical test of the robot is scheduled for 2021. Facebook said, ``By using this robot, the total cost including labor cost, depreciation cost, material cost is expected to be $ 2 (about 210 yen) to $ 3 (about 320 yen) per meter. We expect to have a significant impact on the penetration of the Internet in regions where daily revenues are less than $5.5.

Related Posts: