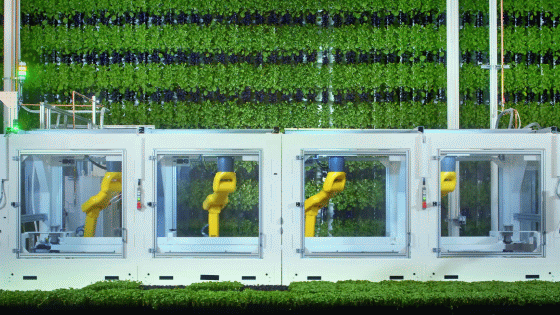

Supporting future food production may be'vertical agriculture 'performed at plant factories instead of fields

In recent years, instead of conventional farming in the fields, '

Why Vertical Farming is the Future of Food-YouTube

People living in the 21st century have a major need to transform traditional agriculture.

The population of the earth is expected to reach 9 billion by 2050 ...

It is pointed out that more food needs to be produced than ever before as the population grows.

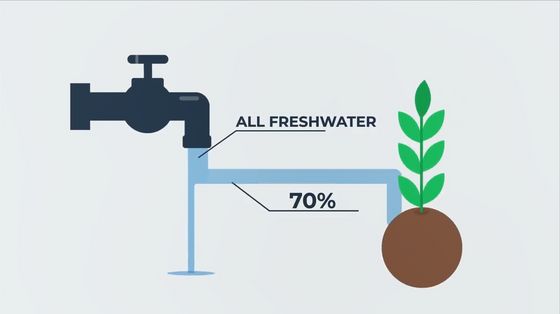

Traditional farming requires large amounts of land and water ...

At the time of writing the article, 70% of the fresh water consumed all over the world is used for agriculture.

As a result, it is difficult for inefficient conventional agriculture to cope with a large population increase.

Throughout history, humankind has carved out forests and grasslands to create farmland, but there is not much new land available for farming.

It seems that the same area as the South American continent has already been used as agricultural land.

Also, due to factors such as climate change,

It is possible that future populations may not be able to eat the nutrient-rich foods needed to survive due to population growth and farmland loss.

A possible solution to the problem of 'producing more food in less space' is ...

It is 'vertical farming' conducted in an indoor plant factory.

Some companies have already entered vertical agriculture with some success.

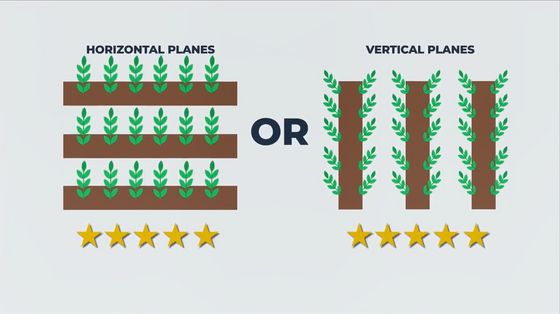

Vertical farming is, as the word says, a farming method that uses space vertically to grow plants.

In conventional fields, you can only grow plants on the area of the ground ...

Vertical agriculture has the advantage that it can use many vertical spaces and grow many plants even in a small area.

If you use this mechanism, you can see the skyscrapers in the city and ...

It is said that agriculture will be possible using warehouses.

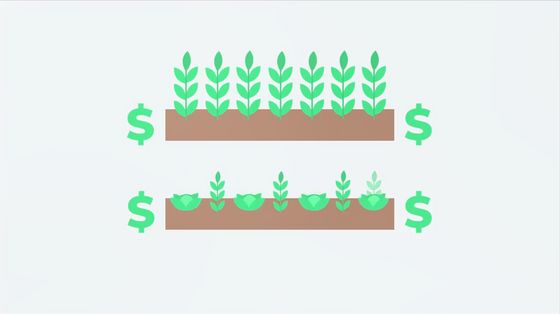

There are four important factors in vertical agriculture: 'physical layout,' 'lighting,' 'medium,' and 'sustainability.'

The physical layout is solved by vertically stacking planter-like media or growing multiple plants using media that extends vertically from the ground. Both methods are expected to increase the yield of crops as compared to the case where cultivation is performed only in a flat space.

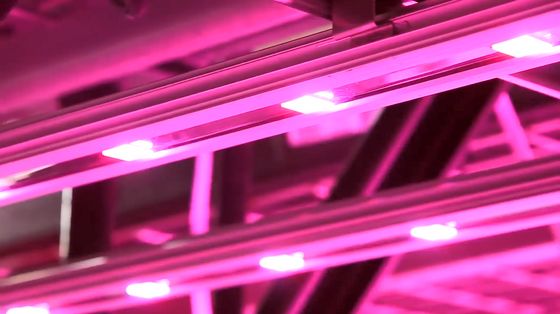

Most vertical agriculture does not use natural sunlight.

Therefore, it is necessary to use artificial lighting to grow plants that grow by photosynthesis.

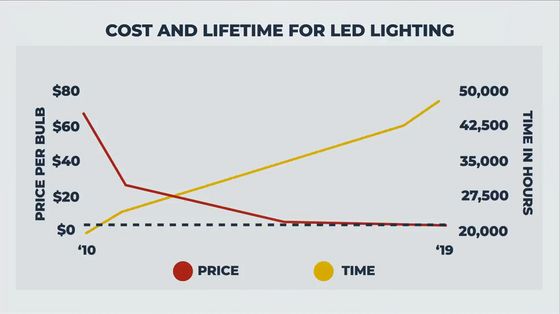

Generally, LED lighting is used for lighting in plant factories, but ...

In recent years, the cost of LED lighting has fallen to less than $ 10 (about 1100 yen), and the duration of the light bulb has increased to about 50,000 hours.

The development of LED lighting makes it possible to significantly reduce the operating costs of plant factories and increase their profits.

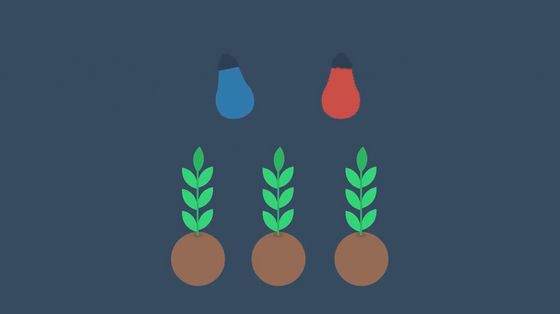

Also, the lighting of plant factories is often seen in purple or pink cases, but ...

This is because the wavelengths of light involved in photosynthesis are blue and red.

It seems that other wavelengths are not required, and from the perspective of energy efficiency, the light from the plant factory is a mixture of two colors, blue and red.

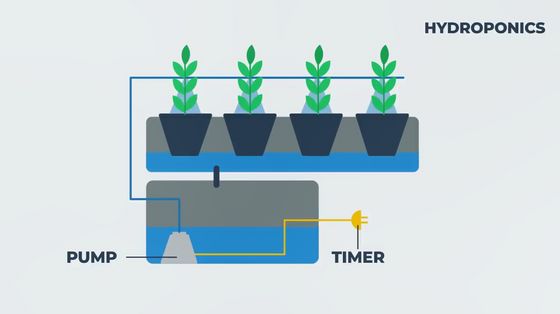

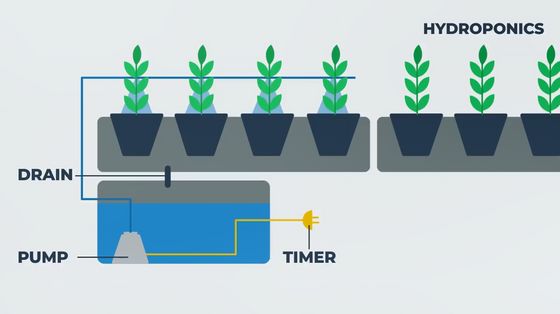

In addition, plant factories generally use a cultivation method that does not use soil. There are three main types of cultivation methods that do not use soil, and there are various methods used by plant factories.

The first is the most common type in plant factories called '

Hydroponics at plant factories has the advantage that it can reduce the amount of water used by efficiently reusing water and that it can easily respond to the expansion of scale.

The second method is called '

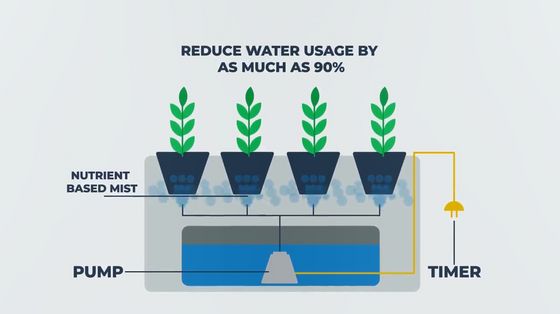

In pneumatic cultivation, water and nutrients are supplied by spraying plants with a fog containing nutrients, which can reduce water consumption by 90% compared to conventional agriculture. It has also been shown that plants grown this way are richer in minerals and nutrients.

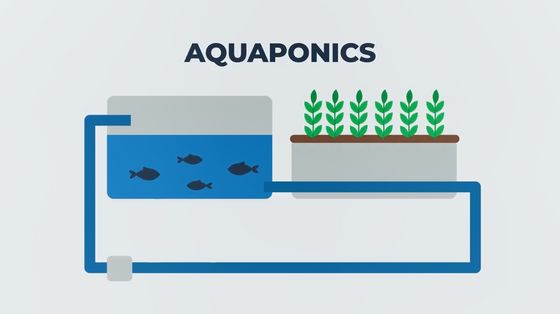

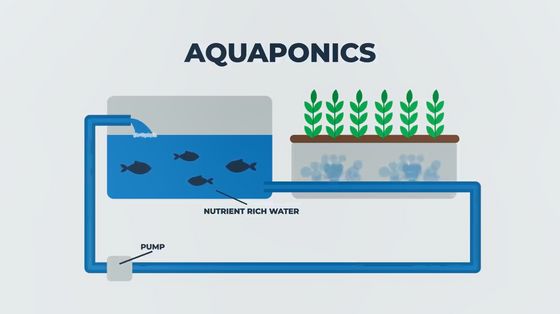

The third method is called '

First, fish are grown in the farm, and the water in the farm that contains nutrients derived from fish excrement is used for hydroponics of plants. The water used for hydroponics is then filtered and returned to the farm again. Aquaponics is a productive and balanced technique, but it is not widely used due to the complexity of combining aquaculture and plant cultivation.

By using these techniques, plant factories can support the world's food supply as a highly sustainable agriculture.

A lot of energy and water are required to operate the plant factory, but it is possible to solve these problems by combining with rainwater tanks and renewable energy.

Converting the center of food production from traditional agriculture to plant factories has advantages over increasing crop yields.

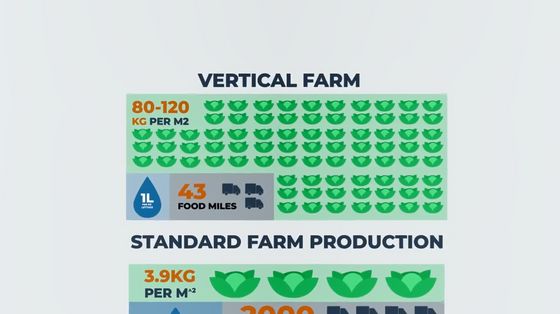

For example, while a typical field can harvest 3.9 kg of lettuce per square meter, it uses 250 liters of water and transports 2000 miles (3200 km) for shipping to retail stores such as restaurants and supermarkets. Must be

On the other hand, plant factories built in urban areas can produce 80 to 120 kg of lettuce per square meter, but use only 1 liter of water. Since it was not made in the suburbs, it would take only 43 miles (70 km) to restaurants and retail stores.

Plant factories can be built anywhere, independent of land and climatic conditions, and produce food all year round.

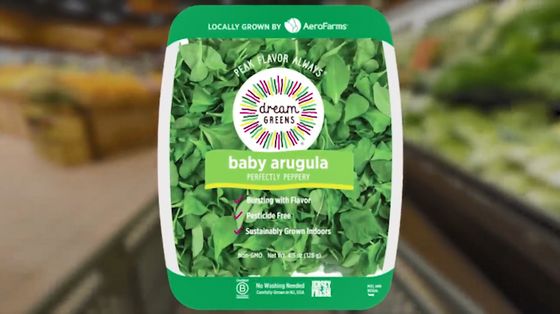

2 million pounds (about 900 tons) of nutritious vegetables can be harvested on this farm ...

It is sold as a pack in a supermarket in the northeastern United States.

In addition, vegetables produced by AeroFarms are also used for in-flight meals such as Singapore Airlines.

The AeroFarms case is just an example.

The movie ended with companies around the world focusing on plant factories, saying that it might not be long before vegetables made in plant factories become commonplace.

Related Posts: