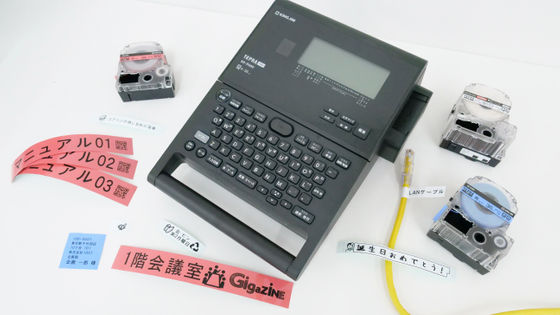

King Jim `` Air Fit '' review that you can easily make packaging materials as you like

From

Air Cushion Maker “Air Fit” Released to Make Packing Materials Easily When Needed | News 2019 | File and Tepla King Gym

https://www.kingjim.co.jp/news/detail/212.html

You can see how it feels when you make an air cushion using “Air Fit” by watching the following movie.

When making packing materials with King Jim `` Air Fit '', it looks like this-YouTube

Included items are main body, instruction manual, power cord, and pole for assembly.

First, attach the pole to the body. A film that becomes the basis of the air cushion is inserted into this pole.

While extruding the film with the parts on the right side of the main body, air is injected from the air vent in the red frame to make an air cushion.

LCD panel and buttons are on the front.

There are 5 rubber feet on the bottom.

The dimensions are approximately width 405mm x height 202mm x depth 270mm. The installation area is slightly larger than

The depth is almost the same.

This is about the height.

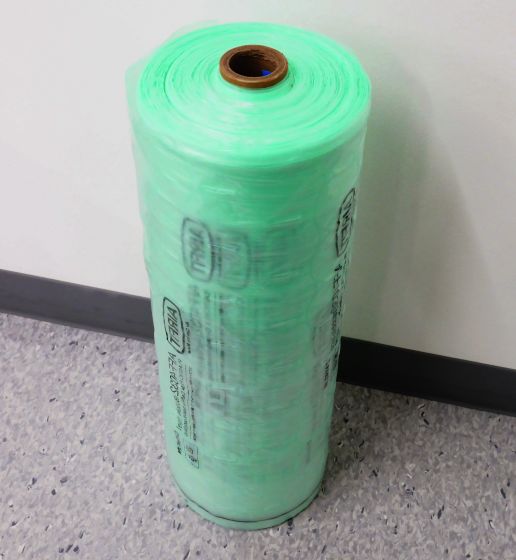

There are two types of film used for “Air Fit”. Pillow type film can make approximately 4000 packing materials per roll.

From a bubble-type film, approximately 875 sheets of packing material can be made in one roll.

I will try using 'Air Fit' at once. Connect the supplied power cord to the power plug on the left side of the main unit.

Turn on the power switch.

The LCD panel turned on when the switch was turned on. “Turn Knob on” is displayed on the LCD panel.

To turn off the display, it is necessary to set the film and tilt the knob on the right side of the main unit.

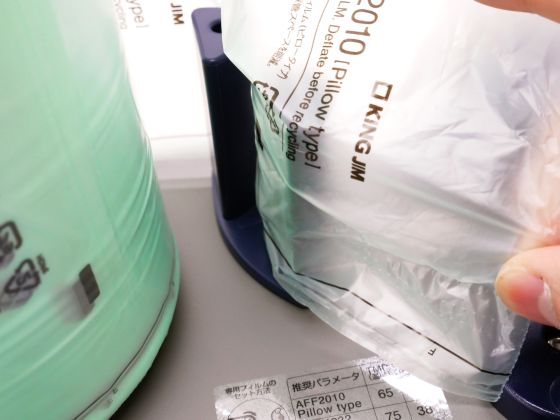

That's why a pillow type film is set in the main body. Make sure that the black line on the film faces downward.

While pulling with the edge of the film ...

I will wind it up in the fixture of the main body like drawing a reverse S-shape.

Once the film has been rolled up, cover the film with the air nozzle. There is a slot on the bottom of the film, and the nozzle is inserted here.

Insert the nozzle into the film.

Pull the film and cover the film deep into the nozzle.

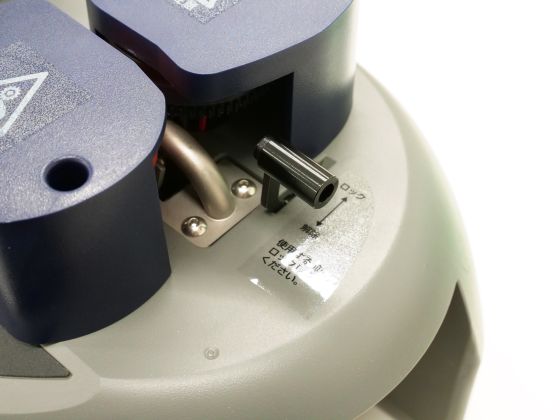

When you have inserted the nozzle to a certain extent, tilt the knob to lock the film.

“Turn Knob on” disappeared and “TMP (temperature)” and “FAN (air flow)” parameters were displayed.

When the parameter is displayed, press the blue “SET” button. The film slides to the right while the button is pressed.

When the nozzle is completely in the film, release your finger from the “SET” button.

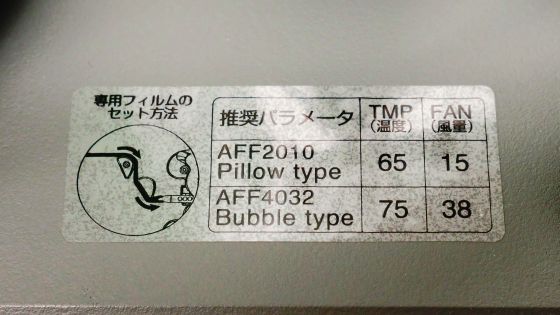

Next, set the temperature and air volume when injecting air. Note that pillow type film and bubble type film have different temperatures and airflow settings.

This time, the packaging material is made of pillow-type film, so the temperature must be set to “65” and the airflow to “15”.

Adjust the temperature with the “+” and “-” buttons on the left.

The “+” and “-” buttons on the right can adjust the air volume.

We were able to adjust the temperature “65” and air flow “15”, which are the default values when using pillow-type film.

Finally, air will be injected into the film. Press the orange `` START / STOP '' button ...

Air started to enter the film.

The film slides to the right as air is injected. The operation sound is

Press the “START / STOP” button again to stop the operation.

The completed pillow type packing material looks like this.

The pillow type is perfect for filling gaps because it can be separated by perforations one by one.

Even with bubble type film, you can create packaging materials in exactly the same way.

Bubble type packing material looks like this. As with the pillow type, it can be separated one sheet at a time.

Each air room is larger than “Puchi Puchi”.

Bubble type sheet can be used as a mat when packing cracks. Click here to see how it was placed in a mug and packed.

Because the sheet is a little large, it is not enough space if the cardboard is enough to fit the package.

I thought that if I could make a sheet that suppressed swelling well, it would be usable for smaller cardboards, so I decided to try making the air volume with a lower “38” than the prescribed “38”.

However, the finished packaging material is almost the same size as the specified air volume, and size reduction has failed.

If you lower the air volume to `` 27 '' and create it ...

This time there was no air at all and the packaging was not completed. It seems better to abandon the idea of adjusting the size by changing the air volume.

We took time to prepare until we were used to creating packaging materials, but once the film is set, packaging materials can be easily created with the push of a button. Since the size of the packing material is adjusted in units of pieces and sheets, it is somewhat difficult to handle small boxes, but if you are shipping in a box of a certain size or more, you will be troubled by the packing material Will disappear.

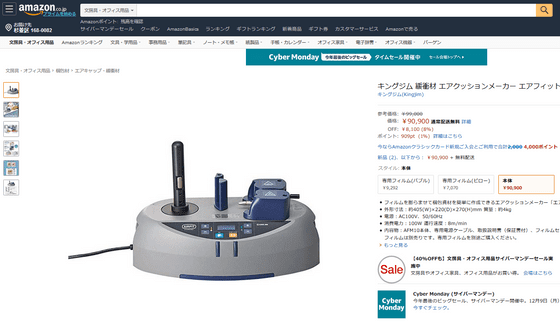

'Air Fit' is sold at Amazon.co.jp, the main body is 90,900 yen including tax, pillow type film 7070 yen including tax, bubble type film 9929 yen including tax.

Related Posts:

in Review, Posted by darkhorse_log