Why mushrooms can help reduce plastic waste?

by

In an attempt to prevent the waste of plastic products that have already been produced from destroying the environment, research focused on extreme microorganisms and caterpillars that produce enzymes capable of degrading plastics is underway. Meanwhile, New York-based biotechnology venture Ecovative Design has started an initiative to reduce plastic waste using mushrooms.

Ecovative Design

https://ecovativedesign.com/

This company is replacing plastic packaging with the root structure of mushrooms-CNN

https://edition.cnn.com/2019/11/13/tech/ecovative-mission-ahead/index.html

Ecovative Announces $ 10 Million in Capital for Launch of launch of Mycelium Foundry-vegconomist-the vegan business magazine

https://vegconomist.com/companies-and-portraits/ecovative-announces-10-million-in-capital-for-launch-of-launch-of-mycelium-foundry/

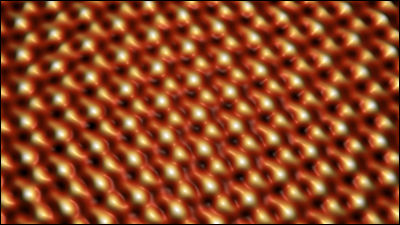

Mushrooms are often thought of as fruit bodies with umbrellas and patterns, such as shiitake mushrooms sold at supermarkets, but Ecovative Design is focusing on the mycelium corresponding to the roots of plants. Ecovative Design has succeeded in developing a mushroom-derived material that can replace plastics by rapidly growing mushroom mycelium into a free shape.

This is MycoComposite, a packaging material made by Ecovative Design using mushrooms, and can be used like a polystyrene foam. All you need to make MycoComposite is wood chips that can become waste, and a little water and electricity. In addition, there is a merit unique to mushrooms, water resistance and flame resistance.

The biggest feature of MycoComposite is that it is easily disassembled and returned to the soil just by placing it on the soil, unlike plastic products that can only be incinerated and landfilled. “Plastic waste pollutes the environment, but mushroom-derived materials become nutrients, not soil,” said Ecovative Design CEO and co-founder Eben Bayer.

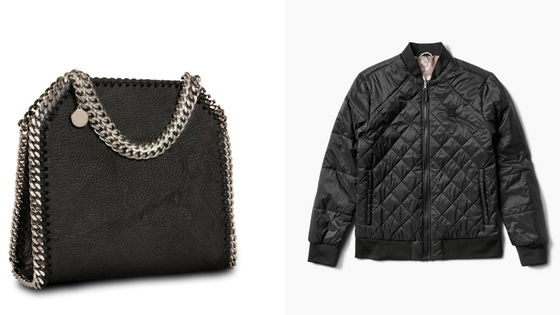

Mushrooms have more possibilities than just packing materials. “MycoFlex”, which is a mycelium fiber, has also been developed.

MycoFlex can be processed like a real leather product, allowing you to make plant-based bags and jackets.

Atlast Food, which is independent from the food department of Ecovative Design, is developing Atlast, a 100% plant-derived bacon.

_m.jpg)

Ecovative Design is currently investing 10 million dollars (about 1.1 billion yen) in research to accelerate the growth rate of mushrooms 10 times. “Mushrooms have unlimited possibilities. My dream is to form capillaries from mycelium one day, and to create organs such as artificial lungs that use human cells. It ’s to create. ”

Related Posts: