A movie closer to the last baseball grab manufacturer in the US is on sale

" Grab ", which is indispensable for baseball, is a very important tool that requires various elements such as strength to catch a hard ball, softness and ease of fit to hand and so on. Many such grab productions are done in developing countries where labor costs are cheap, but a movie closer to the grab manufacturer that is the only producer in baseball power country America is released on YouTube.

The Last Baseball - Glove Maker in America

For baseball players, grabbing the ball is very important.

Many times in the game the player will catch the ball and repeat playing to throw it.

A woman is doing desk work while grab is decorated on the whole wall.

An elderly man who walks is Rob Story.

He is a vice president of Nokona Ball Gloves , the only grab manufacturer with a factory in the United States.

Nokona is a worldwide grab manufacturer headquartered in Nocona , Texas.

"In order to make grabs, it will not begin without leather," Story says, while at Nokona it is making grabs with a variety of leather such as kangaroos, cattle, buffalo, buffalo, caymannium .

If you get heavy and durable leather ... ...

From the place to ascertain the quality of leather, making grabs starts. I often look at the leather with the palm of the palm and check it for scratches and weak parts.

Good quality leather is hard, but grabs need to be loaded as easy to use as possible so that baseball players using grabs can start catch balls etc. immediately.

There were quite a lot of molds in the grab factory.

Push this mold against the leather like a cookie's mold ... ....

I will cut it out.

It is said that 25 pieces will be needed to make one grab.

I am not in the form of grab yet, but I will push the stamp of Nokona into the place in the palm of your hand.

Cut out leather piece by piece, next is the process of applying embroidery on leather. Many sewing machines are running and embroidering the manufacturer name on leather.

At Nokona's factory, he said he is producing 400 to 500 grabs a day.

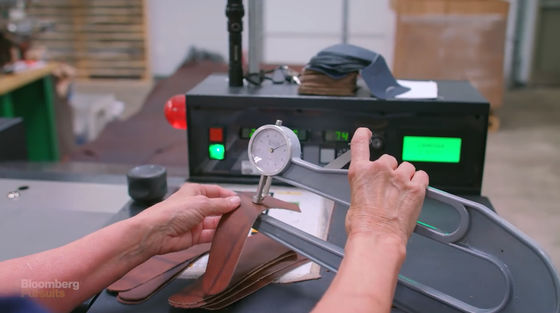

We do not compromise the quality of the glove, so we measure the thickness and hardness of leather parts.

The part where the tested part is carried is the step of sewing each part.

Craftmen handle sewing machines ......

I will sew the parts. The outside and the inside of the grab are sewn together as separate parts.

A glove-like appearance will gradually be developed.

In addition, since the back side of the grab at the sewing stage is upside down ... ...

It is necessary to insert the fingers of the grab into the bar and correct the front and back.

Subsequently the grab was fitted into a metal appliance shaped like a huge hand.

It seems that this appliance is heated to about 120 degrees ...

Heat while stretching the leather, and then clapping it with a Tonkachi will shape the shape of the grab seams and fingers cleanly.

According to Mr. Story, it is impossible to make Nokona grabs in places other than Nocona. Story says that Nokona people working at the town and factory in Nocona are indispensable elements for manufacturing grabs.

Story is the fourth generation counted from the founder of Nokona. My grandfather, Bob Story, chose the way to continue making grabs locally while other manufacturers moved factories abroad in the 1960s.

Several decades later, Nokona became the only grab manufacturer in the United States to do domestic production.

Each employee works in various forms of employment and it is possible to realize how to work according to his / her lifestyle. The skilled craftsmanship necessary to make grabs is said to be worth getting so.

The grab consists of two parts, "back" where the hand directly touches and "table" to catch the ball. After combining the two ... ....

I will paste various parts such as fur and lining which are near the wrist.

In addition, there are also work to pass strap through 120 holes opened in gloves and sew it.

Furthermore, I will paint a petroleum-based adhesive like " cosmorin " like peanut butter.

It seems that when you bond with cosmolin, you can not peel off the bonded surface even after 10 years.

Furthermore, we sew the part which corresponds to the pocket of the grab with the strap.

There is also a process to hit the ball catching portion with a hammer in order to make the grab fit.

This gives the grab adequate softness and at the same time forms it so that it catches easily, and wrinkles disappear.

Sprinkle evenly to form a layer of oil on the surface of the grab ......

Dry for a while.

Finally the glove is completed.

It enters a bag and is sold at a price of $ 290 (about 33,000 yen).

It takes a lot of time and effort to make a single baseball player's grab.

Related Posts:

in Video, Posted by log1h_ik