In the factory of Boeing "assembly wing robot" is being assembled daily by the assembly work

As for Boeing's best selling machine "737 type aircraft", production is carried out at a high pace of 42 machines per month as of 2016. To make 42 aircraft, that is, to make 84 main wings together right and left, it is necessary to complete two or more main wings a day even if full operation every day. In such a factory specialized for 737 aircraft of such Boeing, the robot to assemble the main wing is working every day.

Boeing's Panel Assembly Line (PAL) Robot Builds Jet Wings | WIRED

https://www.wired.com/2016/10/meet-giant-robot-builds-boeings-wings/

The robot introduced to the factory is called "PAL (Panel Assembly Line)". You can see the actual operation etc in the following movie.

Meet the Giant Robot That Builds Boeing's Airplane Wings | WIRED - YouTube

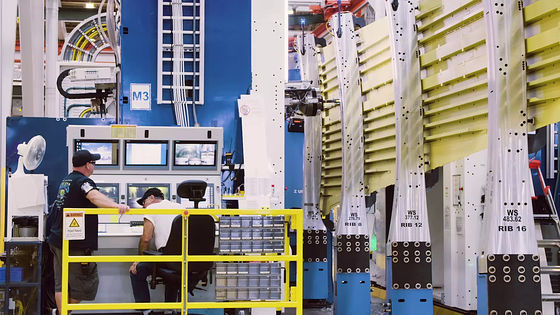

Blue gate (gate) type robot is PAL. The structure is such that the main wing vertically enters the gap in the center, and the entire machine is assembled back and forth like a car wash machine at the gas station. Incidentally, although it is similar to a car wash machine, the size is about 6 meters high, and the weight is 60 metric tons of a huge robot.

Preliminary preparations by humans are carried out before actual assembly. First, set on the jig a yellow part called "spar (girder)" to secure the strength of the wing attached to the inside of the main wing.

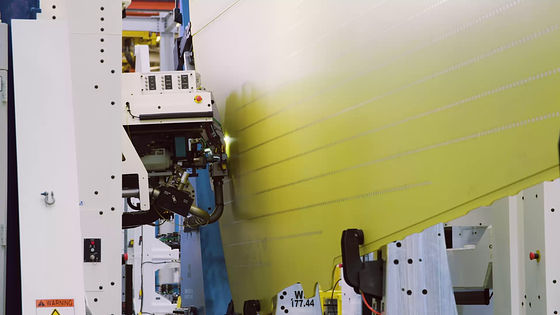

Then prepare a metallic panel to be the wing surface of the main wing ......

Temporary work at the actual mounting position.

First of all, it is fixed with rivets called "zipper" by human hand.

And assembly by PAL started.

I will do positioning accurately and quickly using laser.

At Boeing's factory, there was a main wing assembly line that was used since the 1960's, but in the current line which introduced a new robot, the time required for assembly has been reduced by 90%.

Because it is a work by robot, it is said that the worker's skill variance and the trouble due to mistake drastically decreased. In addition, it seems that we could reduce the cost required for training workers because we repeat the same work many times after programming once at the beginning.

The robot will accurately determine the position of the fastener, open holes and silently combine the panel and spar with fasteners.

Assemble the panel and spar, then join the two panels above and below with a human hand to form a box, the main wing is completed.

In Boeing, it is planned to raise the production capacity of 42 aircraft per month by 2016 to 52 aircraft by 2018. That's why it's getting popular with the 737 aircraft of small aircraft, so it seems that the activity of this robot PAL will continue in the future.

Related Posts: