Currently in Tesla's ultra huge battery factory "Giga Factory" scheduled to be operated by 2020

Tesla of the EV maker aims to be fully operational until 2020 and is the world's largest super-huge battery factory in the suburbs of Reno, Nevada "GIGA FACTORYWe are proceeding with construction of. The BBC is infiltrating into the construction site of GIGA FACTORY, which is said to be "reckless plan" as well as "dream factory" because of too spectacular plan.

Inside Tesla's gigantic Gigafactory - BBC News

http://www.bbc.com/news/technology-36893104

GIGA FACTORY, which TESLA is under construction, is a production facility aimed at producing all the lithium ion batteries used for electric vehicles (EV) produced in-house, and all the batteries produced here are TESLA It is supposed to be installed in the EV that it plans to produce 500,000 units annually. The construction budget amounted to about 5 billion dollars (about 520 billion yen), and the total site area combined with the factory and surrounding land is 3,200 acres (13 square kilometers) wide. This is an unimaginable extent that simple calculations exceed 4k vertical x 3k horizontal, so calledTokyo DomeIt corresponds to about 280 pieces when converted to. Equipment such as wind power generation will be made in the premises.

Construction of GIGA FACTORY started in June 2014, and it is planned to start production of battery cells in 2017. Even after that, production equipment continued to increase and aim to reach maximum production capacity by 2020, and the number of lithium ion batteries produced in one year at full production is produced worldwide in 2013 It is expected to reach a scale that exceeds the total number of batteries.

In addition, Panasonic in Japan is greatly involved in the construction of GIGA FACTORY. Tesla and Panasonic have partnered to produce EV batteries so far, Panasonic is investing about 2 billion dollars (about 210 billion yen) in constructing Giga Factory. (However, according to the reporter of BBC "It was not enough to put Panasonic's name in the factory name"

The state of Giga Factory as of July 2016 is kore. It is said that 14% of construction has been completed, and the necessary equipment for battery manufacture is beginning to be carried in already completed buildings.

At the location of Giga Factory there is a new place name "Electric Avenue Sparks, NV 89434" (Sparks, Nevada, Electric Avenue). When Giga Factory operates in earnest, the Nevada state government receives measures such as tax incentives from the Nevada state government because about 10,000 people are born locally and economic effect can be expected.

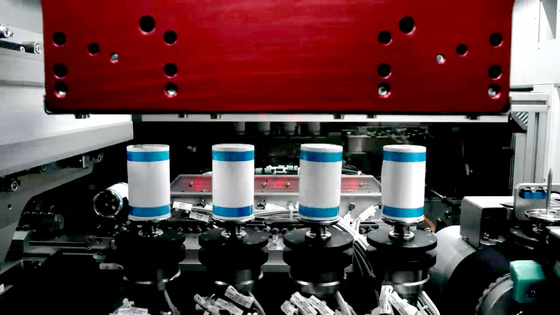

Tesla's CEO Eulon Mask took part in the interview and said that he explained it. It seems that photographing of the interview was severely restricted because of the factory where the latest equipments line up, and the guide in the factory tour also prohibits the comment "This machine is what machine, what this machine creates" It was that it was.

The inside of the factory is three stories, it is divided on the floor of Panasonic and Tesla. A hole for material transportation is drilled on the floor, the flow of transporting the cell produced by Panasonic to Tesla and making the final finish is to produce the cell in Japan, cross the Pacific Ocean, to the Tesla plant in the USA It seems that the flow to be carried in is reproduced as it is.

Looking at the numbers related to GIGA FACTORY in a row, it looks like the following.

· Planned construction cost:$ 5 billion(About 520 billion yen)

· Total site area:3200 acres(13 square kilometers)

· As of June 2016, the total production equipment14%Correspond to1.9 million square feet(177,000 square meters) completed

· Once completed, the production facility5.8 million square feet(Approx. 540,000 square meters)

·1000 peopleConstruction workers are in charge of work, construction is2 yearsI am going ahead of schedule

· By 201835 gigawatt hours(GWh), which will be more capacity than the battery produced worldwide in 2014. Production scale is maximum150 gigawatt hoursIt can be increased to a considerable extent.

Tesla is advancing the construction of GIGA FACTORY and aims at reducing the cost of the battery by taking advantage of the scale merit of large scale production. Especially, if the price of the battery, which is said to occupy the majority of the cost of the EV, falls, it will be possible to lower the vehicle price, so for Tesla, which is planning to release the "Model 3" of the popular price range EV, The success of Giga Factory has become a major fortification division.

In this way, although it is a giga factory that has become a huge investment to greatly influence Tesla's future, there seems to be situations in which it can not be said that sailing smoothly. There is a delay in the construction plan and partnership relationship with the partner and there is a view that the yellow signal is lit up in the "30% reduction in battery cost" aimed, and some construction workers are boycotting the work There was also a report that the content was reported.

"Tesla 3" production also affected? Rumors concerning construction of battery factory WEDGE Infinity (wedge)

http://wedge.ismedia.jp/articles/-/6263

Nonetheless, as Mask CEO announces "Master Plan · Part 2" showing the next 10 years, it is absolutely impossible to remove this Giga Factory in order to realize the concept of expanding EV from passenger cars to bus trucks It seems that it is the most important point that can not be done. Interest will be gathered as to how Tesla's strategy, which is said to have even the possibility to change the future global energy policy, will be advanced.

What is "Master Plan · Part 2", which Mr. Taska's mask shows for the next 10 years, such as solar power generation, low price EV, car sharing? - GIGAZINE

Related Posts:

in Note, Posted by darkhorse_log