Boeing introduces a wearable device "Google Glass" to improve aircraft production efficiency and reduce mistakes

Millions of parts are used on one aircraft and various ingenious efforts have been made to assemble them quickly and reliably. Established on July 15, 1916, just today, on July 15, 2016 20th anniversary of aerospace development enterprises celebrating the 100th anniversaryBoeingMeanwhile, efforts are being made to improve the efficiency of aircraft manufacturing sites using Google's wearable device "Google Glass".

Google Glass takes flight at Boeing | CIO

http://www.cio.com/article/3095132/wearable-technology/google-glass-takes-flight-at-boeing.html

Recent aircraft have been digitized, and many wires are used not only for aircraft control systems but also for in-flight entertainment for passengers. As a result, as many as several kilometers of cable are running around the plane, its manufacturing is also very complicated.

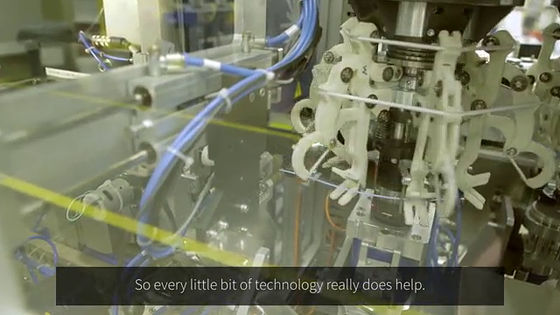

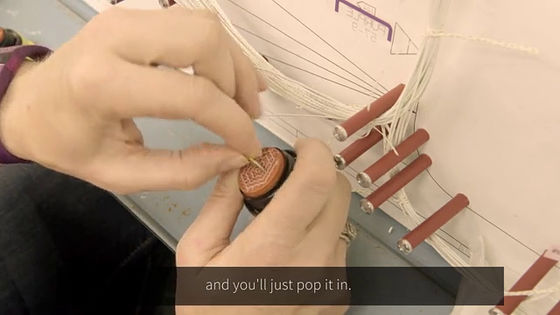

In order to realize complicated wiring, we do not do wiring in the machine suddenly at the manufacturing site, but work to make the cables and connectors assemble to the required length and shape in advance in another place in advance.

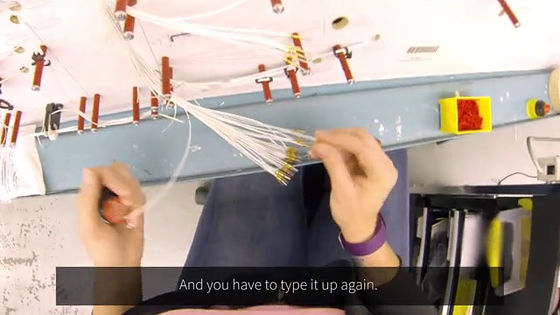

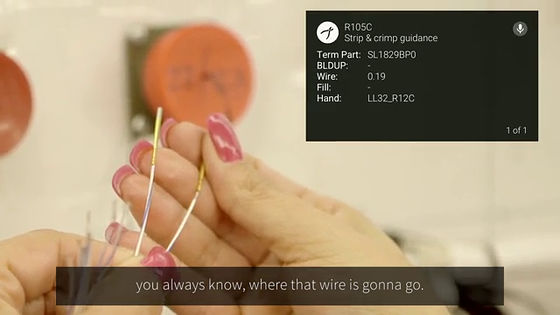

Even a single connector has a variety of shapes. All wiring is specified finely at the design stage, so no manufacturing mistakes are allowed.

When assembling work, we will route cables one by one with people's hands, using a dedicated jig (route) drawn in advance as described above. Traditionally, details of the wiring were indicated in the paper specifications ......

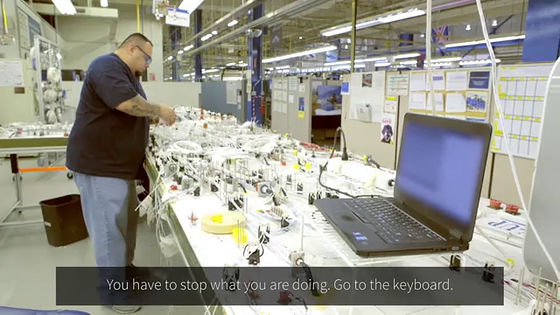

Eventually, it changed to display the specification on the notebook PC.

Even when making this change, it seems that efficiency is higher than the paper specifications so far, but in order to obtain the necessary information, the worker went out of the way to the front of the laptop PC, You have to hold your hand and operate the keyboard.

You can see how it looks even with the image of the camera attached to your head. Bend the body 90 degrees to a notebook PC placed next to the workspace, check the details on the screen ......

Return the body to its original orientation and do the work. With this, it is inevitable that the work efficiency is not good and the worker's body is also burdened.

For this reason, efforts have been made to replace parts that can be automated with robots at the site of manufacturing, and to cut down the work time by several seconds while reducing the burden.

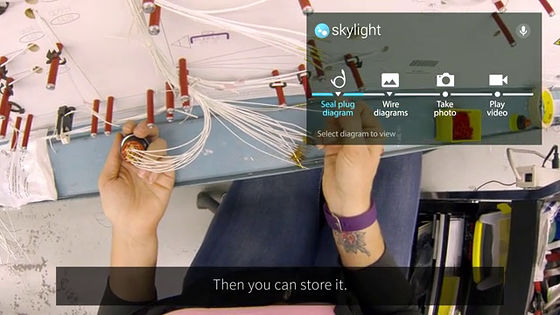

However, what accelerated its evolution dramatically was that of APX labs'SkylightIt was called a system called. Skylight uses Google Glass and displays the necessary information on a small display above the eyes.

Skylight | APX Labs

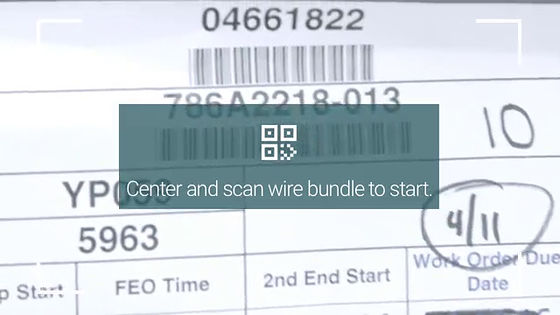

Boeing cooperated with APX Labs and promoted efforts to utilize skylight at the aircraft manufacturing site. When approaching the shelf where the part is placed, speak to "okay, skylight" and enter voice command into Google Glass. Here we do the work of putting together cables, so speak to "Start wire bundle (start bundling of wire) ..."

Next, "Scan order (command to scan)" command.

Then the Google Glass camera reads the bar code posted in the box containing the part and gets necessary data from the data center.

After reading like this, we pick out parts.

Then arrange parts to work place. Here another staff seems to be in charge of work.

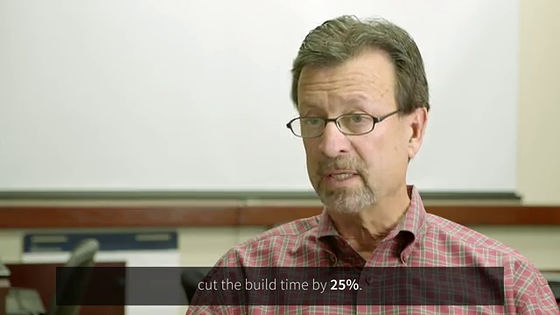

Mr. Randall McPherson who is in charge of system development said, "By adopting these mechanisms, it is now possible to" 25% shortening time "rather than minutes in minutes or seconds."

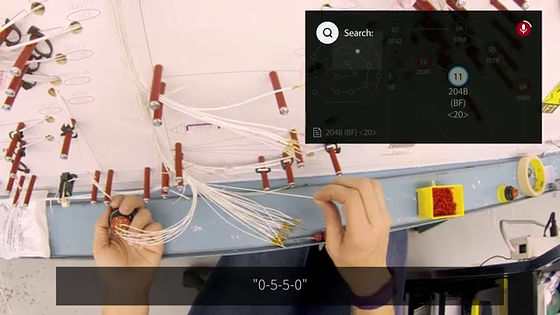

The staff who is in charge of work also installed Google Glass. Talking to "OK skylight" ......

"Local search"

Enter the number of the cable you want to check by "0-5 - 5 - 0".

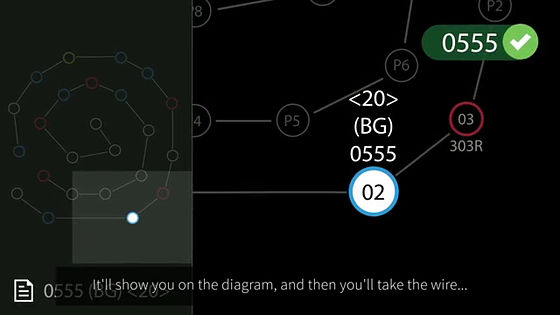

Then skylight showed where to place cable "0-5-5-0" on Google Glass's display. The following image simulates what the actual workers see.

In a system using a conventional notebook PC, it was necessary to stop work and search by searching the keyboard ... ... If you are skylight, simply enter the keywords you want to examine by voice, We will display the necessary information before.

Therefore, the worker can continue working reliably without stopping his hand.

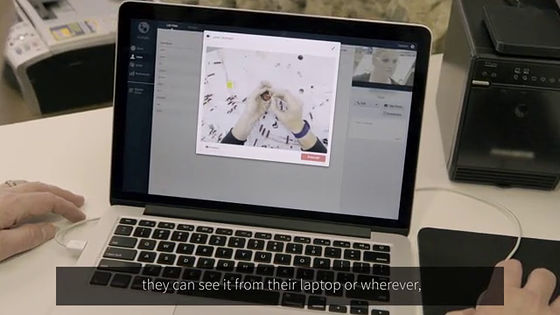

Also, by using Google Glass it is possible to transfer the situation of the work captured by the camera to a remote place. Even if you are having trouble with your work, you can transfer images to the responsible person's PC in this way and ask for necessary instructions. The side who received the consultation will also be able to give reliable instructions while watching the actual appearance.

Furthermore, it is also possible to save the state of the work as a movie.

Even if the staff got lost, by displaying the correct work procedure on the display, you will be able to reach the correct answer quickly.

All of the tremendous cables running around the cabin are neither properly nor useless as one. Therefore, it is extremely important to work reliably.

In addition to the accuracy of such work, it is skylight that Boeing and APX labs have been developing to improve efficiency.

Boeing was interested in improving work using Google Glass from around 2013 and had a partnership to develop in collaboration with APX Labs in 2014. It is said that the use of skylight will be promoted also in the manufacture of the aircraft itself because the usefulness of the cable manufacturing site was recognized.

Related Posts: