A movie in which an extremely small robot under 1 yen coin makes their own tools or coalesces into another robot

One of the largest research institutions in the world established by Stanford University in 1946 was "SRI International(Hereinafter SRI) ". In this SRI, we have created smaller robots than the American 10 cent coins (smaller coins than Japanese one yen coins), and these extremely small robots have various abilities. And the latest mini-robots can not only assemble robots other than themselves, but also can make tools for minimal robots to use themselves.

SRI's Micro Robots Can Now Manufacture Their Own Tools - IEEE Spectrum

http://spectrum.ieee.org/automaton/robotics/industrial-robots/sri-micro-robots-can-now-manufacture-their-own-tools

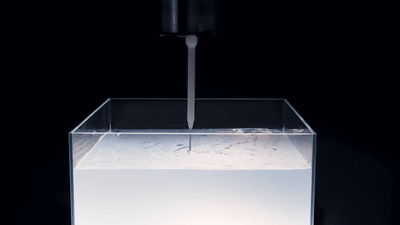

Several years ago, SRI launched the "MicroFactory Platform" plan of "making robots to make small structures" using hundreds of extremely small robots. In the first place, in order to produce a complicated structure using a miniature robot, it is necessary for a plurality of extremely small robots to cooperate closely. In that case, each robot will be assigned a specific task, but if it is too boring then SRI researchers think, "Minimal robot is our own customEnd effectorWe will create a tool factory that can develop ", and MicroFactory was created as a factory for robots.

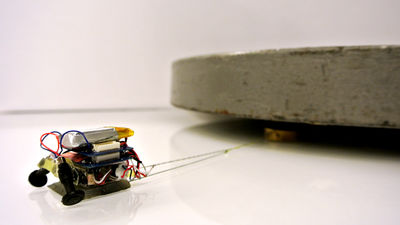

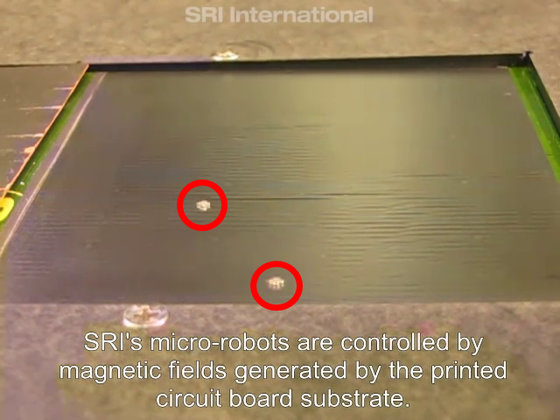

SRI's smallest robot is like a small magnet, and programs built into the built-in printed circuit board control the movement and speed by manipulating the robot itself like an electromagnet. The following movies show how SRI's minimal robot moves and how you can use tools.

Magnetically Actuated Micro-Robots for Advanced Manipulation Applications - YouTube

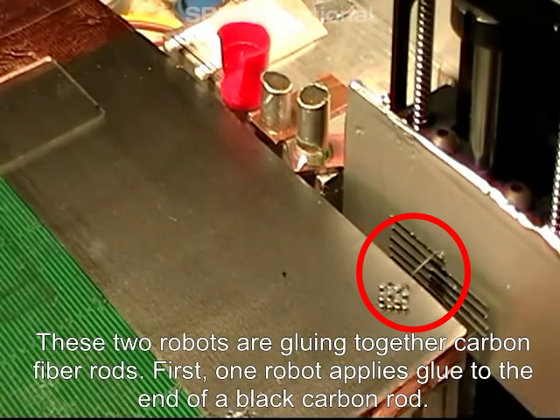

The smallest robot in the area surrounded by red circles below. It moves around freely by controlling the electromagnetic field generated by the built-in printed circuit board.

Minimal robot (red circle) can move at high speed, maximum speed is 35 cm / sec.

You can also run zigzag at high speed while avoiding the three obstacles in the red circle.

In addition, it is possible to climb the wall vertically as follows.

Besides, if it is a smooth curved surface, it seems that you can freely move about.

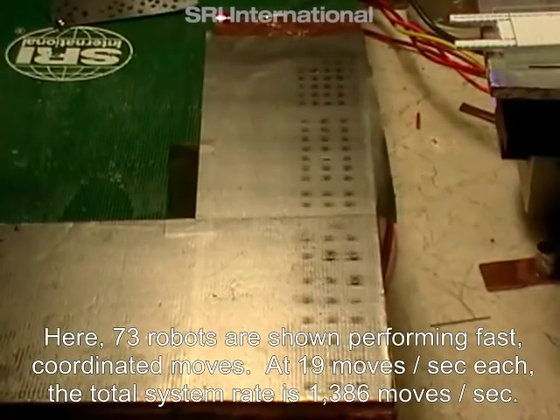

The following photographs show 73 minimal robots, which are repeated 19 times per second.

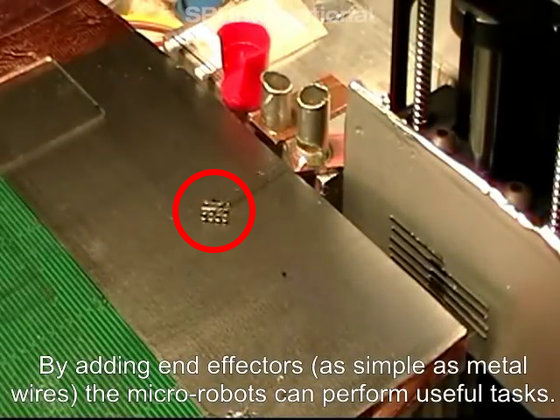

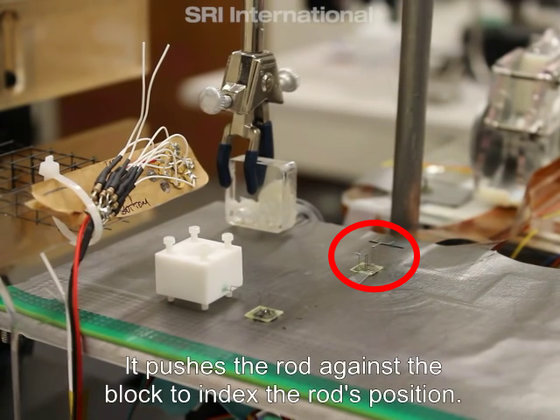

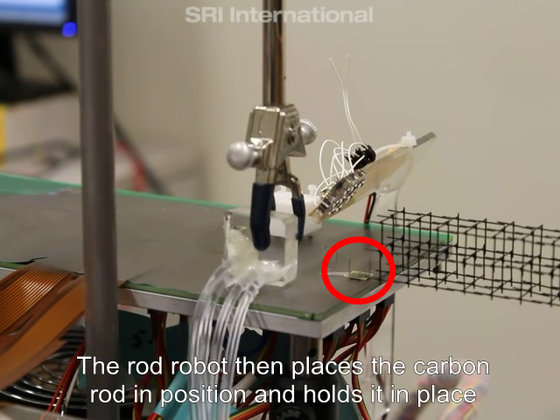

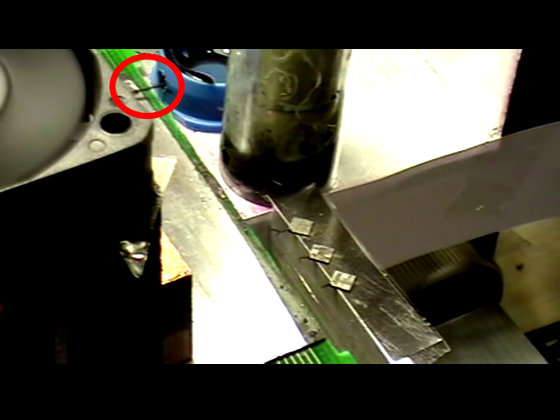

In the red circle part is a micro robot attached with a rod as an end effector.

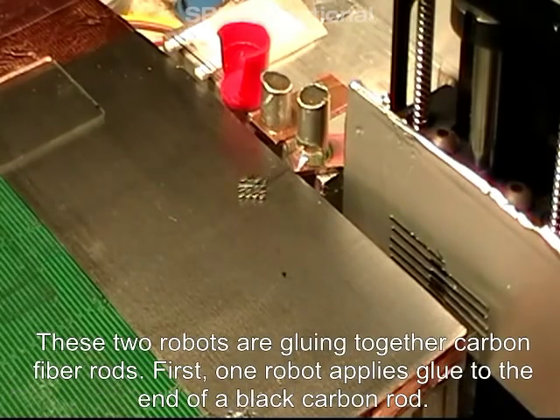

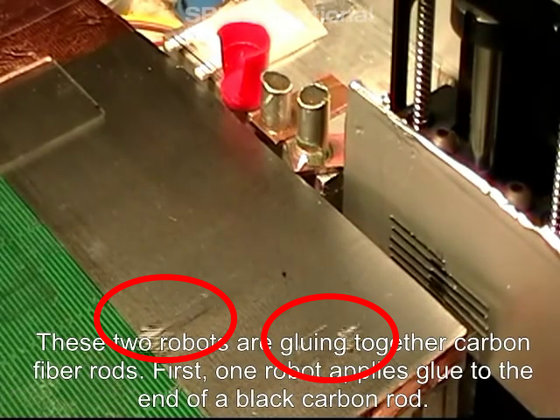

Push this stick into a silver cylinder ... ...

Push the stick against the wall. This is where I put the adhesive on the wall.

When the adhesive is put on, the robot goes down and another new robot appears.

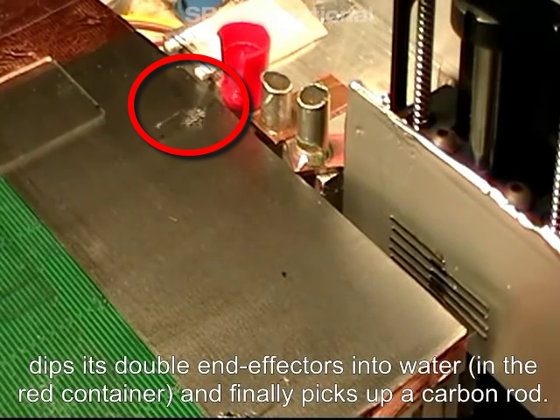

The new robot presses the bar against the red container ... ...

Lift the black carbon rod.

And it's perfect on the wall.

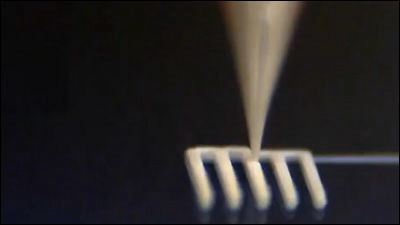

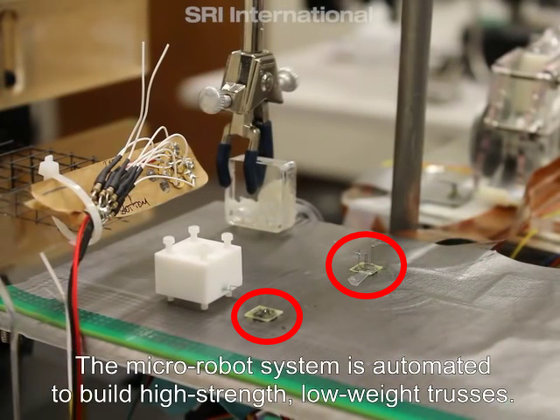

A demo that starts trying to create a high-strength truss structure using this extremely small robot starts.

The robot moves ......

I brought a carbon rod that is a truss structure material.

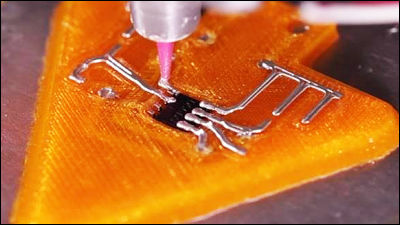

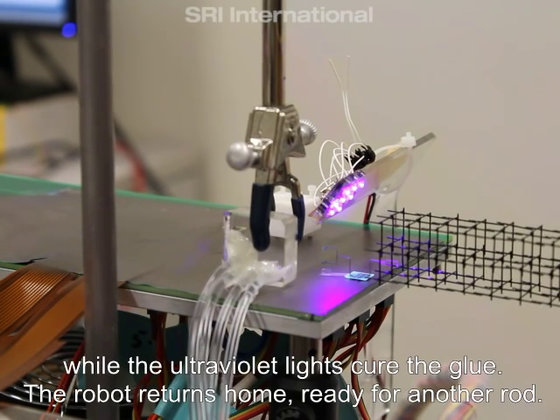

Then, another robot paints adhesive on the part where the carbon rod is attached and sets the rod.

And if ultraviolet rays are applied and the adhesive is cured, the truss structure is completed.

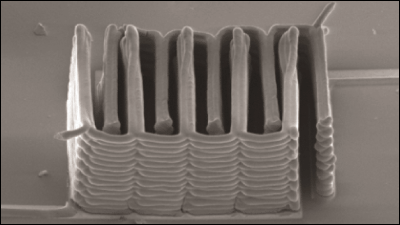

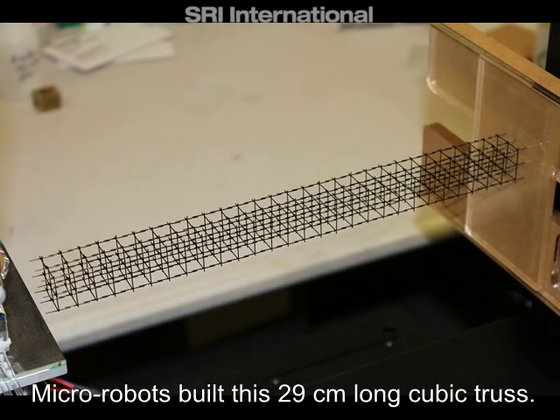

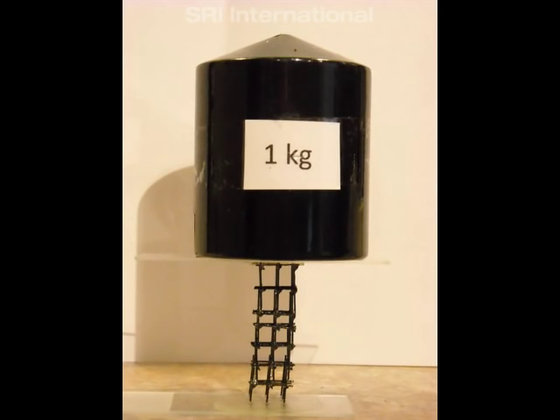

A truss structure of 29 cm length made by repeating this.

Truss structure made with micro robot is very solid and can support various weights.

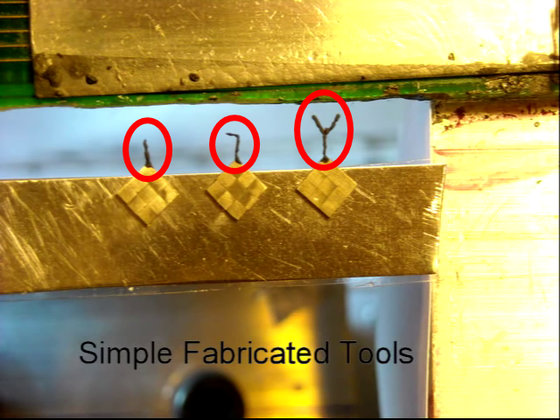

In this way, it is possible to perform various tasks with the extremely small robot, but basically, different end effectors are attached to the same robot. In other words, in order to do something with an extremely small robot, you have to change the end effector attached to the robot every time, which is almost the same effort as creating different robots.

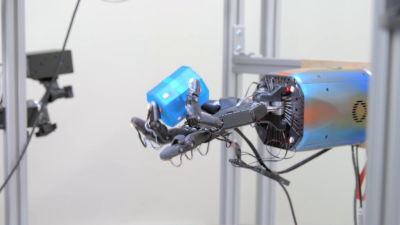

Therefore, SRI is conducting experiments as to whether it is possible to work efficiently by using a tool (end effector) created by an extremely small robot. In the following movie, you can see how the tiny robot assembles him / herself and how the same micro robot is building the tool used by the micro robot.

SRI Micro Robots Self Assembly & Tools Fab - YouTube

A small point in the red circle part is a very small robot which becomes a part constituting the robot.

This enters the structural part made of slide glass and copper wire called "incubator" ...

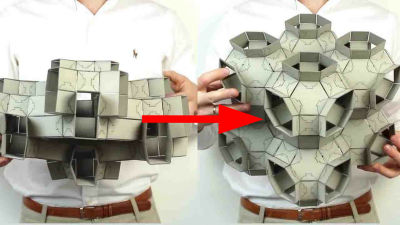

Attaching each robot, a new robot with dog's name is born.

The following robot is made up of five parts, but it seems that the number and shape of parts are flexible.

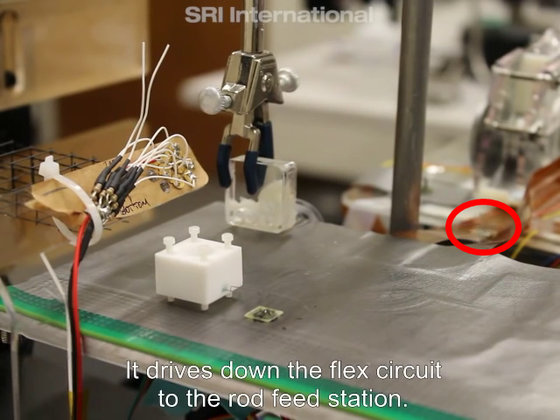

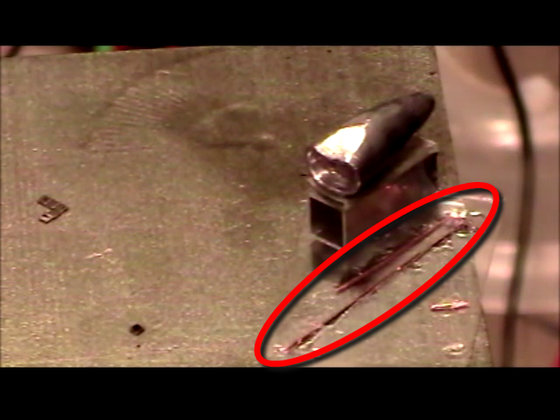

And in the next movie the robot in the red circle pushes the stick into the blue container ......

Next push the stick into a silver container ......

Finally I hit a stick to a micro robot.

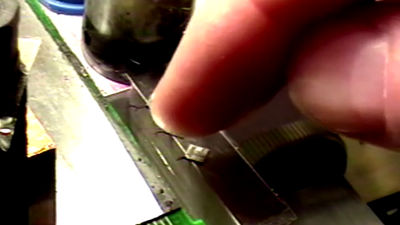

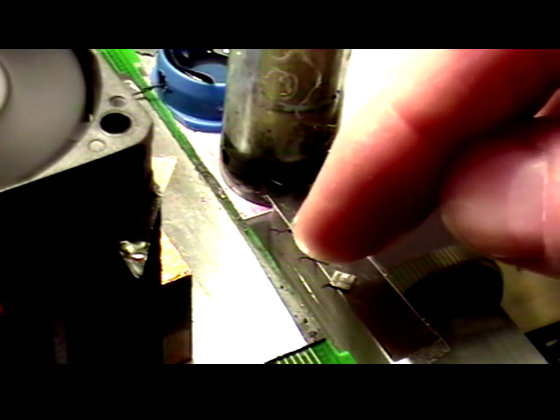

The robot is very small, this size even compared with fingers.

What I was doing by sticking a stick to a micro robot was that I made my own variety of sticks in the red frame part.

"MicroFactory" in which micro robots make robots and tools themselves is much faster and more efficient than purchasing robots for specific uses and purchasing robots that can perform various tasks and buying tools according to the purpose And that.

Furthermore, rather than sliding on the ground, SRI seems to be working on a new movement method "to move the robot while floating in the air using magnetism". If it becomes possible to float in the air, it will be possible to realize a smaller robot of 200 nanometers.

Ron Pelrine, developer of MicroFactory, said that this extremely small-sized robot technology has the potential to revolutionize traditional automation technology, and that it may also be active in a wide range of fields beyond manufacturing relationships doing.

Related Posts: