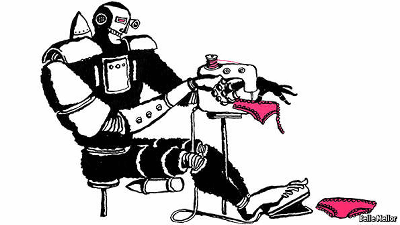

A robot sewing machine that produces clothing items in full automatic robbing sewing industry in developing countries

In the near future, the robot may deprive human's workConcern is rising and controversial. It is pointed out that the trend of complete mechanization and automation is getting stuck in the clothing industry as well, and the work of developing countries is deprived.

A robotic sewing machine could throw garment workers in low-cost countries out of a job | The Economist

http://www.economist.com/news/technology-quarterly/21651925-robotic-sewing-machine-could-throw-garment-workers-low-cost-countries-out

Manufacture and sewing of clothing material, which is a material of clothing items, are handled in countries and regions where labor costs are inexpensive, such as in developing countries, because manual work is necessary. Until the other day, it was in China that was manufacturing many of the clothing items, but due to the rise in personnel expenses accompanying the development of the Chinese economy, the production site of clothing has passed through from Vietnam, Bangladesh from China, recently Myanmar and other countries have shifted to countries where personnel expenses are inexpensive.

ByArian Zwegers

However, there is an indication that the movement to move production bases in search of this cheap personnel expenses may be terminated by the appearance of a fully automatic sewing machine (robot sewing machine).

Simple tasks such as weaving, cutting, and attaching buttons and stitches have already been fully automated. However, it is relatively difficult to switch the actions, such as connecting different kinds of fabrics, finishing the edges of the fabric, etc. Human hands are necessary. However, with the development of IT technology, the appearance of machines that overcome the hurdles of these work is near.

"Yore and deflection of the fabric is no longer a matter of the past" says Steve Dickerson, who was a professor at the Georgia Institute of Technology. Mr. Dickerson is currently developing a company called SoftWear Automation in Atlanta, USA, and is developing fully automated technology for manufacturing clothing. We used high performance cameras to capture the state of the fabric in detail, sewing based on that information, and trying the method of recognizing the edges of the fabric and sewing it while folding back.

BySusanne Nilsson

The technology of SoftWear Automation is to grasp the state of the fabric from the contrast that changes momentarily by the super high speed shooting of 1000 frames per second. This technology acquired a patent in 2012, and from DARPA it got $ 1.3 million (about 1 We have won a research cost of 160 million yen). In 2014, we also succeeded in making robot sewing machines that can sew different material fabrics. It seems that we have already succeeded in developing technology for sewing with accuracy that is superior to skilled workers.

Also developed an arm for a robot sewing machine called LOWRY. LOWRY has a suction type pickup arm, it is possible to pick up different kinds of materials and deliver them to other machines. In other words, by installing LOWRY in a robot specializing in cutting and robot specializing in sewing, it is possible to complete the task of manufacturing clothing such as cloth cutting and sewing with a robot-only team.

Fast fashion brands such as GAP, UNIQLO, ZARA, etc. are business models that emphasize on consuming products at an earlier cycle than before, keeping costs down by mass production. Therefore, he seems to tend to dislike the time loss caused by manufacturing clothing overseas, he said he is very interested in fully automatic clothing manufacturing robots.

ByElvert Barnes

Mr. Jack Prankett of Market Research Company Plunkett Research said clothing companies that have production bases in Asia have taken a keen eye on how wages can be reduced and their eyes are robots that can produce clothing in full automatic He says he is suitable for sewing machines.

In addition, it is not only in the clothing field but also in the shoes industry that there is a high interest in producing goods without adding any human hands at all. CurrentlyIt was output using 3D printerAlthough sneakers of an unprecedented design are attracting attention, in the near future, it seems that research to make shoes by outputting softer dough with a 3D printer is in progress.

Related Posts:

in Note, Posted by darkhorse_log