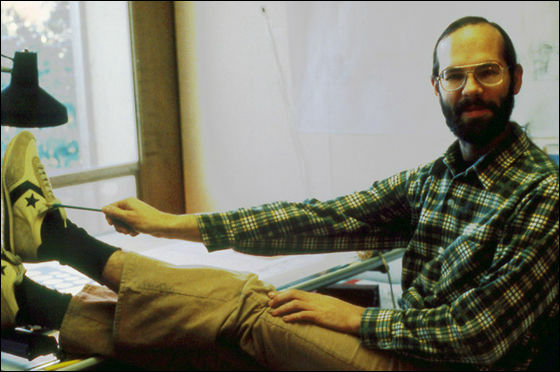

A person who designed an Apple mouse talks about his own career and teaching to the next generation

Even if it is said that there is no one who has not touched now, the reason why the mouse for PC popularized so far is not overstated, was released in 1983 by AppleLisaIt is said that it was adopted for. I was involved in designing such an Apple mouse, and later gathered a lot of popularity as a mobile information terminalPalm VIndustrial designers who have made numerous achievements such as bringing innovation into the design of the company,Jim YulchenkoHe will retire in August 2014. In the interview, a 35-year career as a designer and the teaching that we want to get from there and tell the next generation is told.

The Engineer of the Original Apple Mouse Talks About His Remarkable Career | Design | WIRED

http://www.wired.com/2014/08/the-engineer-of-the-original-apple-mouse-talks-about-his-remarkable-career/#slide-id-1423461

Mr. Uruchenko who later becomes an industrial designer entered to study art at Stanford University in the mid 1970's. Mr. Urchenko, who was blessed with a chance to participate in a student workshop soon after, says he spent a lot of time there. There, he received influence from interaction with many other students, learned various techniques and got wider goal.

Later, based on this experience, we decided Jurchenko's work style that absorbs knowledge and experience by looking at every place, and creates new ways from there. In the course of a long career, an episode that ultimately decided to devise instruments and facilities to realize products that are difficult to realize beyond the frame of the original product designer tells Mr. Jurchenko's work I will.

Although he is a craftworker Yurchenko who obtained over 80 patents through his career, when I started walking as a designer I have little experience and it seems that it was in a state of "just improvising according to the situation". It is Mr. Yurchenko talking about the situation at that time, "If we knew more than one thing more than the client, it was just a" prospect "by itself", but some of its clients include Steve - Mr. Jobs was also included.

◆ Design an Apple mouse

Around a few years after I graduated from Stanford University, I will call a telephone under Mr. Uruchenko. The other party is a friend of college age, later famous design consultancy companyIDEOIt was Mr. David Kelly who invited him to work on a newly launched design farm. At that time Mr. Uruchenko was involved in another medical startup company, but the compensation at that time was a stock, not cash, and it was decided to ride the invitation from Mr. Kelly who is paying properly It was. Also, as co-founder of the company with Mr. Kelly had a connection with Jobs, Apple became one of the very early clients of the company.

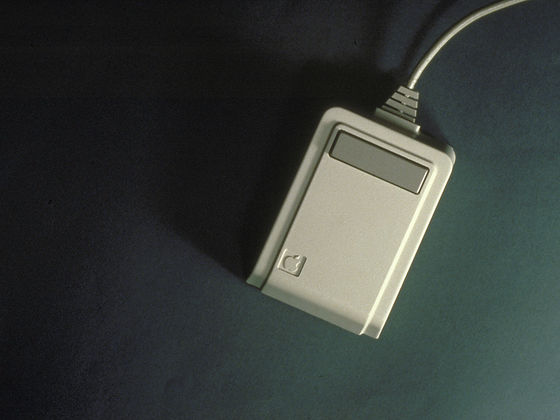

At that time Apple came up with Lisa's design, and Mr. Jobs was at the Xerox laboratory in Palo Alto when he found a future in the graphical user interface (GUI) that is awashward by the world. Since Apple's internal engineers were obliged to design the GUI, there was a task for Mr. Yurchenko to design a mouse.

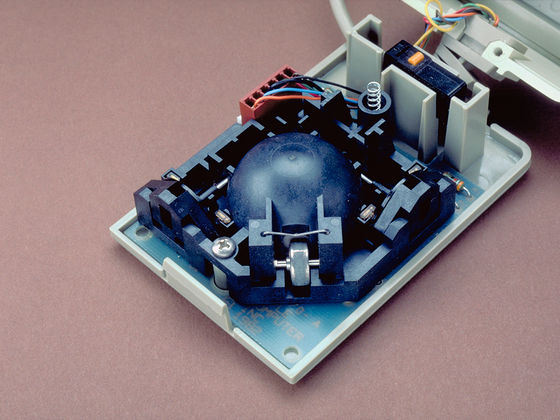

At that time, the mouse developed by Xerox was complex and very expensive but Mr. Jobs dislikes it, demands that it be simpler and cost-saving design. Medical level parts were used for the Xerox mouse and a complex mechanism was incorporated, but Urchenko's team found a new answer to the trackball mechanism that Atali, the gaming machine manufacturer, had , We succeeded in realizing nearly equivalent operability with a simple mechanism.

In addition, there are interesting episodes about mice. One day, Mr. Yluchenko suddenly said that he noticed that "the user is not concerned about the tracking accuracy of the mouse, I do not mind that!" What the user sought is the result obtained by manipulation, and as a result of noticing that it is not the accuracy of the mouse itself, it succeeded in further reducing the number of parts and costs of the mouse. It is an episode that talks about the best example of development focusing on the user experience.

Later this mouse was a huge success, from which the same basic components will continue to be used over the next few years. About the process, Mr. Yluchenko said "Although it was a few simple discoveries, by seriously working on it, the way the product should be is visible, and we can see how we design it It is said.

◆ gain experience in manufacturing

The experience gained by Apple's mouse making has served as the cornerstone of IDEO and continues to live. In the point that one of them said that "actually making things," Yurchenko looked back then and said, "I was always making something, I was building prototypes as soon as possible, sloppily and quickly" I will. IDEO said that it has done such work much earlier than CAD, 3D printer, NC machine tool and so on.

Unlike the present age where design, modeling, and manufacturing programs are all done on software, it was an era when there was only "paper and pencil" at that time in design. And the experience of the design that Mr. Yulchenko got at Stanford University was basically the design of one article like "small volume production" or so-called "one off". However, it is totally different thing to actually make products that are mass-produced at the factory and are on the market and it is said that there was hardly any experience on the site of product manufacturing in the end.

Mr. Yluchenko looking back at the actual site looking back at the time said, "We have accumulated know-how for now, but at the time there was no knowledge at all. We had to accumulate know-how one by one by repeatedly seeing craftsmen who created the molds when making, and actual production line etc. We absorbed knowledge and we gained know-how for product design Although it was supposed to be reflected, the learning curve in the first few years was very gentle. "

In making products, facilities called "molds" for molding plastic parts are used, but due to certain restrictions on the design of molds, the design of the final form product is within the limits of that It is required to do with. In the beginning, Mr. Yluchenko probably had no choice but to comply with that restriction, but while acquiring experience, in the meantime, next time we gained know-how to reflect our demands on the manufacturing process including molds We will go.

ByDanny Choo

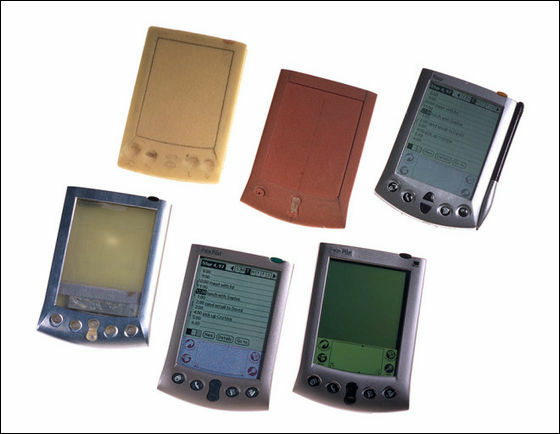

One of the representatives of IDEO's products was Mobile Information TerminalPalm VThere was a request from the client "thinner" was received. In order to realize it, Mr. Urchenko reverted to the manufacturing process and carried out a drastic review of the body structure. We abolished the "screw fastening" of the main body which has been used in many of products so far, and use adhesive of type that uses heat "Hot melt adhesiveIncorporating methods such as assembling products with "has responded to many difficult demands.

◆ advice to go backwards

Mr. Uruchenko's background can be talked almost in line with the evolution of computers. Regarding that change, Mr. Urchenko cites that "usability elements have come to be adopted from the very beginning of the design". How users use products and how to misuse them. In the modern age where the design was considered in consideration of requirements such as what kind of mistake it is, how to prevent it, if it is assumed that the user wrongly uses it due to the design , It is not the user but the responsibility of our designers, "Yulchenko says.

In addition, designers with higher abilities point out that there is no point of contact with the facts of the manufacturing process. Mr. Uruchenko has gained a lot of experience when growing up as a designer, but the current designers think that the problem is that the experience is lacking, technological innovation advances and the prototype is 3D printer etc. In modern times where it can be done very quickly, I am worried that the spectacle of overseas factories actually manufacturing products will be forgotten.

ByGeir Halvorsen

Mr. Yluchenko advises youngsters who will play a leading role in the future "to ask the same question to everyone".

For that reason, Mr. Yluchenko said, "When I studied about molds, I first went around to the factory and went around what I was doing, as each answer came back, Despite being the same product, the process of getting there was different for everyone.I have repeated this 300 times, but because of that it makes 300 kinds of molds from one mold I got to learn the answer and got more knowledge than anyone who actually asked in. In this way, by acquiring more knowledge about manufacturing, as a more capable designer You can acquire the knowledge of the. "

Even in modern times where computers develop and most of the products are completed on the desk, it seems that actual knowledge of manufacturing and manufacturing sites is indispensable.

Related Posts: