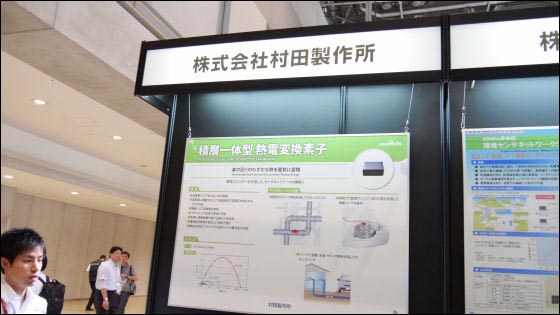

Murata Manufacturing 's "Integrated Layered Integrated Type Thermoelectric Conversion Element" which can generate electricity by utilizing the temperature difference with the size of rice grain size and can be used as a power source of the heat source attachment sensor

Murata Manufacturing has succeeded in miniaturizing as much as it can be installed in various sensors attached to the heat source by laminating thermoelectric conversion elements that can generate electricity by using the temperature difference and can be utilized as a power source of the sensorIntegrated laminated thermoelectric conversion element"Wireless Japan 2014Exhibited at. We actually demonstrate to drive the sensor by generating electricity with the sensor attached to the heat source itself.

Power generation characteristics of stacked oxide thermoelectric modules and their application to energy harvesting devices |

http://www.murata.co.jp/corporate/ad/article/metamorphosis16/paper/02/index.html

Murata Manufacturing booth is small enough to overlook mentally.

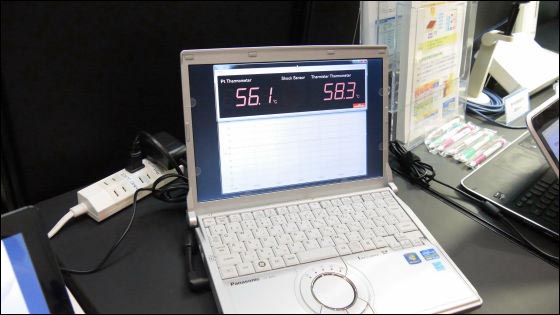

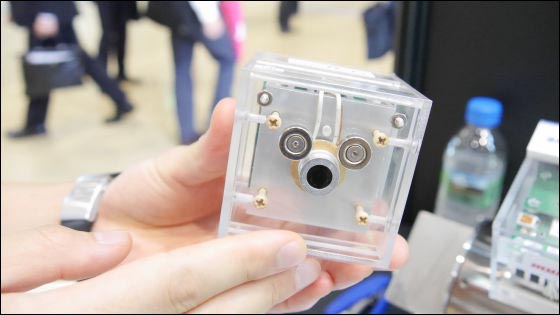

We were demonstrating a laminated integrated thermoelectric conversion element. The metal part is high temperature of about 60 ℃, this heat is converted to electricity and supplied as the power of the sensor.

This is a PC that receives temperature information wirelessly from the sensor. Certainly the temperature sensor can monitor the temperature of the metal part.

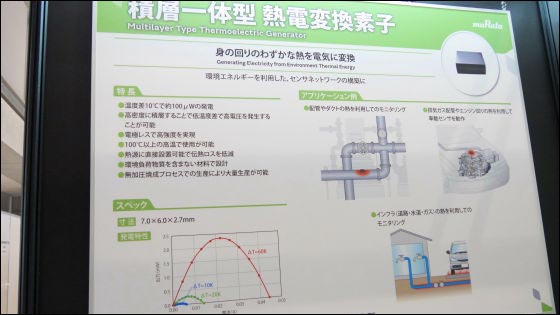

Integrated lamination thermoelectric conversion element can generate power of about 0.1 W at a temperature difference of 10 ° C and can be used at high temperatures of 100 ° C or more and if incorporated in a sensor attached to an automobile engine or piping that generates heat, You will be able to monitor the status without taking power.

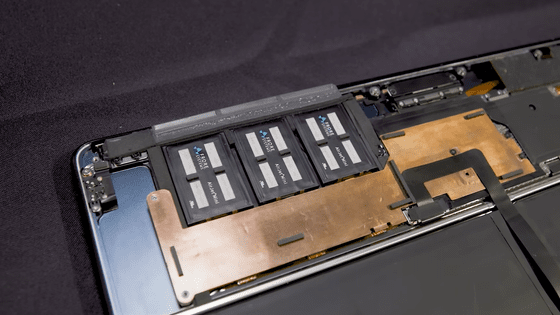

A laminated integrated thermoelectric conversion element is a laminate of 25 pairs on the left and 50 layers on the right. It can be used even in space-saving by laminating it.

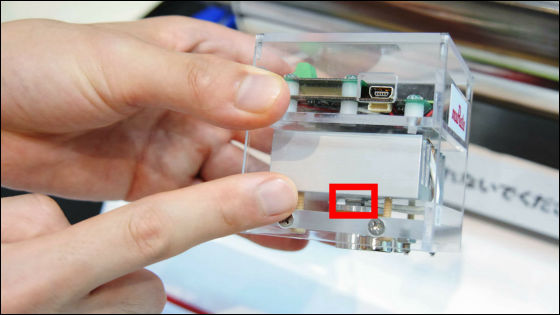

This is a temperature sensor incorporating stacked integrated thermoelectric conversion elements. Below the heat sink that we are pointing out is a laminated integrated thermoelectric conversion element.

Black heat source contact part ... ...

It can generate electricity by utilizing the temperature difference between the heat sink and the air layer that dissipated heat.

Integrated multilayer thermoelectric conversion element is extremely small, it can drive various sensors without preparing power supply separately, so it seems that it can be expected to introduce it to home appliances as well as application of industrial sensors.

Related Posts: