A teenager develops an electric prosthesis made by 3D printer by himself, what is its purpose?

Mechanic prosthetic hands are expensive, and in the case of growing children, they need to be replaced, so it is not easy to get out of hand. Trying to make cheap and high performance electric prosthetic hands using 3D printers as much as possible is done by teenage boys. Currently in the development stage of the prosthesis, to make it more sophisticated, the cloud funding platformKickstarterInvestment is being recruited at.

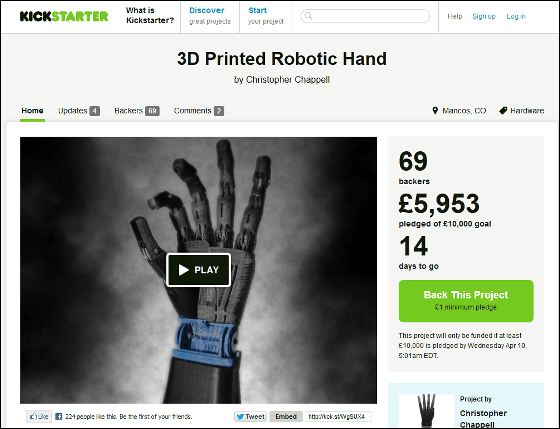

3D Printed Robotic Hand by Christopher Chappell - Kickstarter

http://www.kickstarter.com/projects/anthromod/3d-printed-robotic-hand

You can see the actual movement of the prosthesis from the following movies.

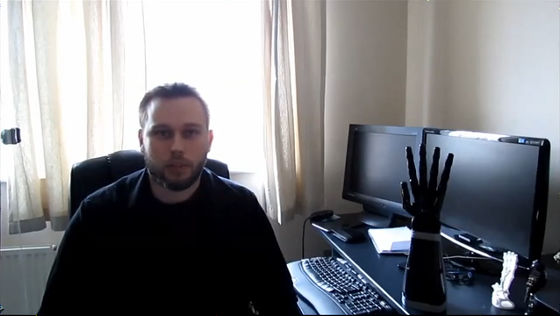

This is Easton LaChappelle who is developing. I remember my dream of making electric hand held by my childhood when I was a child, studying engineering on my own, and I was second in engineering competitions in Pittsburgh. Currently I am studying nanotechnology at the University of Manchester.

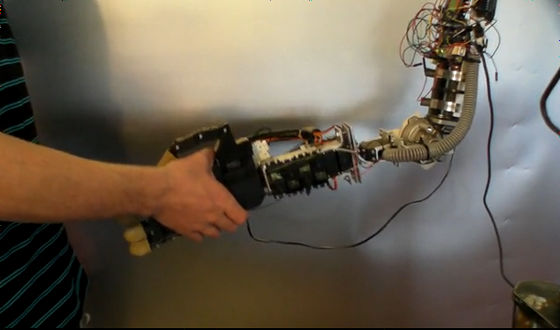

Chris Chappell, a collaborator, is putting a prosthetic hand made by a 3D printer at the desk.

Mechanic prosthesisHas been developed so far, but it was very expensive and easy to get out of hand. Mr. Easton met an 8-year-old girl who wore an 8 million dollar prosthesis, but looking at her suffering from having to change expensive prosthetic hands as it grows, it is as cheap and as expensive as possible I decided to make a performance myoelectric prosthetic hand, and worked on creating a prosthetic hand made by 3D printer.

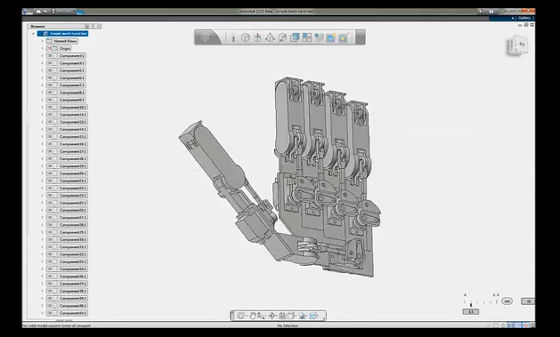

The design has been reworked many times.

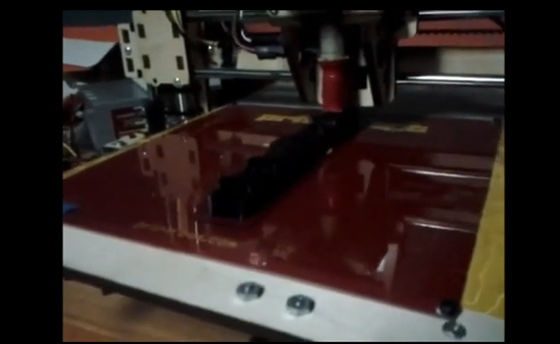

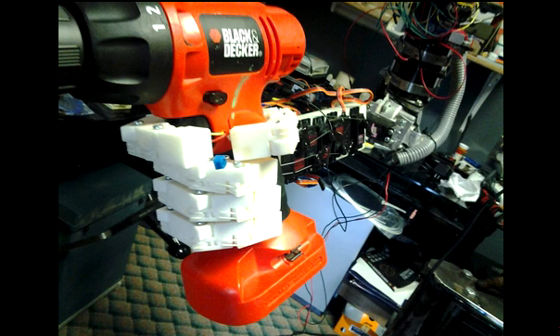

It seems that the prosthesis is 3D printed.

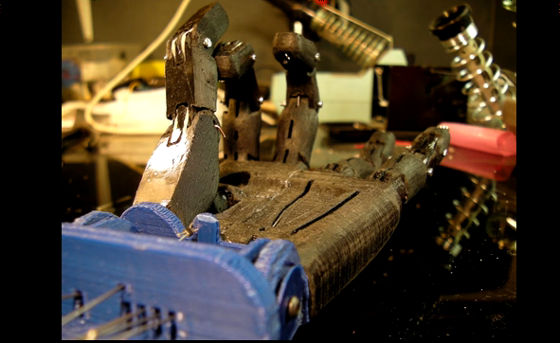

This is the prototype.

Prosthetic hands can move fingers and wrist joints. Version 3.0, the latest version of the test work, features a microcontroller, amplifier circuit, Bluetooth, the user deflates the muscles and selects the menu,It is possible to control. The angle of the wrist can be adjusted in six stages, and the finger can be moved as you like. Also, rubber is used to reproduce the movement of the tendon, and the joint can be moved smoothly.

I can also shake hands like this.

Of course it is easy to grasp something, too.

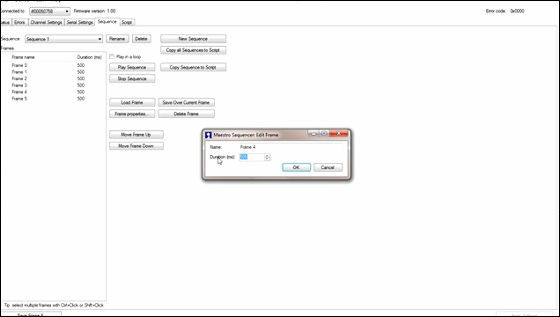

Also, software for controlling artificial hands will be distributed for free. Because the software is open source and simple to set up, anyone can make and use artificial hands without special skills, and even if the parts are damaged, repair and restoration are easy by using the 3D printer at hand You can do it.

We will also create a customized version of finger design.

Prosthesis is currently recruiting necessary funds for development. Depending on the funds we gathered, we are also considering installing various sensors and making them with lighter materials. We got one assembled finger with a contribution of $ 15 (about 1400 yen), $ 80 for a palm (about 7500 yen), 500 dollars (about 47,000 yen) to get a wireless controllable prosthesis, Investment is necessary.

The deadline is 18:01 on April 10 in Japan time.

Related Posts: