How to assemble rifles that can be shot by live ammunition by making parts by 3D printer

We created a part by using a 3D printer, assembled the original rifle and actually shoot the process until the American men ownedblogIt is open to the public.

◆AR10 Lower assembled | Ambulatory Armament Depot

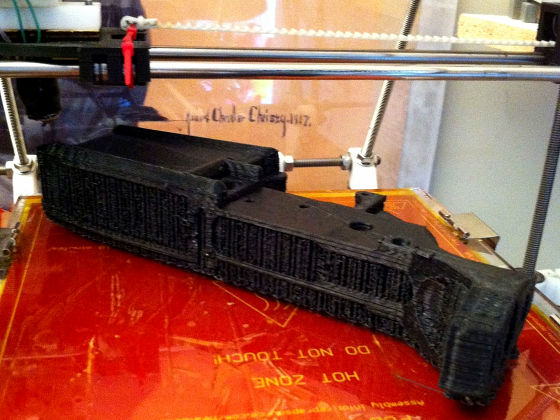

In the first post related to the self-made rifle parts, the photographs of the parts immediately after being molded with the 3D printer are posted together with the sentence "almost (successful) to the assembly of the AR10's lower receiver". In addition, the lower receiver is a part that installs a magazine, a trigger, a stockbed and others.

Following are the finishing and installation of the ready-made grip.

◆Bored | Ambulatory Armament Depot

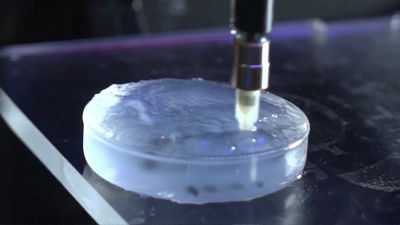

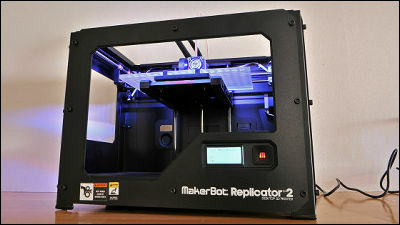

In the next post, I shoot a movie using a printer to show how parts are being formed. In the main text of the blog is a sentence written as "I'm doing a lot of things" but the work is too serious.

Ar10 print - YouTube

◆AR10 Lower V2 | Ambulatory Armament Depot

The combination of a lower receiver that improved part warping etc. and a separately purchased ready-made magazine is as follows.

This part is connected with the part which connects the stock of the rifle and so on called the buffer tube (stock tube).

It is this part that expanded the surface area to eliminate warpage of parts. Even under the current situation, when you look at the bottom right of the photo, the part where you insert the magazine you can see that the parts bow slightly, but in the next version you want to work on improving around here.

◆AR-15 lower failure, new spools. | Ambulatory Armament Depot

A separately prepared rifle for taking out parts such as muzzle and hammer that can not be molded with 3D printers.

Although it seems that it was the state that only the parts are combined afterwards, an accident occurs in which the part to which the buffer tube is attached is damaged.

◆AR-15 Two-part lower | Ambulatory Armament Depot

Changed to design to divide the lower receiver into two so as to solve the problem of breakage ahead. The following are new parts.

When connected with a buffer tube it looks like this.

AR-15 Grip and Stock in Print | Ambulatory Armament Depot

Another part is like this.

The two are listed below.

A photograph comparing the "initial version" on the bottom side of the photo and the "split version" on the top side is like this.

◆AR-15 Assembled | Ambulatory Armament Depot

The original rifle is completed by combining your own parts and commercial parts you purchased earlier.

I saw the lower receiver molded with a 3D printer and my own stock up.

The pictures of the size compared with the cat that the author keeps are as follows. It is not a shot-killed prey.

◆AR-15 Firing Video | Ambulatory Armament Depot

The movies that actually shoot the completed rifle at the shooting range can be seen below.

Firing rifle with printed lower - YouTube

So, bullets, magazines, upper receivers are taken from commercial items, but grips and stockbeds that influence the stability at shooting are completely self-made. It seems that it is a practical level finish as far as the image is seen, so the era in which 3D printers are widely used as a means of making custom parts according to their own physique may come out as soon as possible.

Related Posts: