MIT researchers developed a method for manufacturing high-quality, high-volume sheets of "graphene" which is a dream material

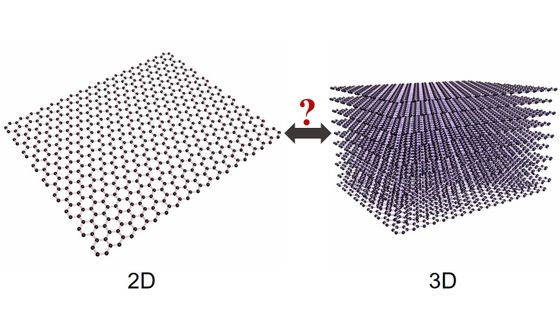

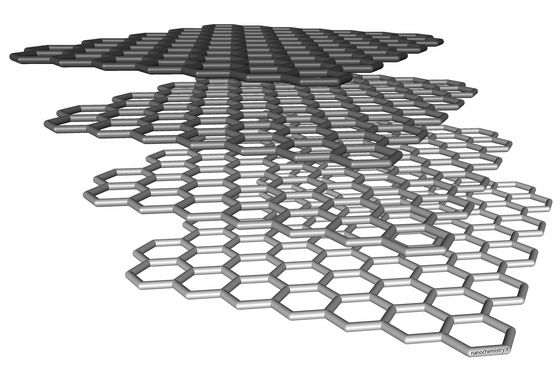

"Graphene"Is a sheet-like substance formed by bonding carbon atoms, surprisingly light and soft, having strength higher than iron,Both superconducting and insulatingIt is a material that is expected to be applied to various fields from properties such as. Researchers have developed methods to produce such graphene like a long cloth.

A graphene roll-out | MIT News

https://news.mit.edu/2018/manufacturing-graphene-rolls-ultrathin-membranes-0418

The research team at Massachusetts Institute of Technology has devised a method of continuously producing high quality graphene like a cloth, and has reached the stage of actually prototyping a graphene manufacturing machine. "For several years researchers have been thinking about manufacturing graphene as an ultra thin sheet,"John HeartAssociate professor says that graphene can be used as seamless ultra thin film covering integrated circuits.

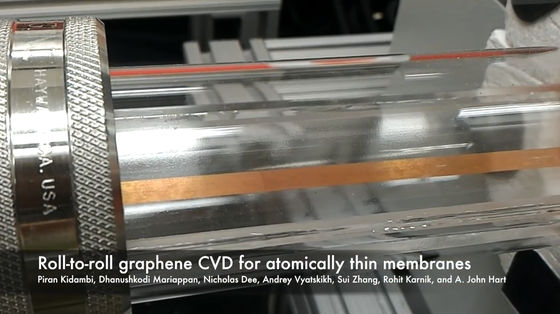

The production movie of ultra thin graphene developed by the research team can be seen from the following.

Roll-to-roll graphene CVD for atomically thin membranes

Many researchers believe that graphene can be used as an ultra thin film filtration filter. A piece of graphene is very strong and it becomes a high-performance filter which can not penetrate even helium atom depending on the bonding pattern of carbon atoms.

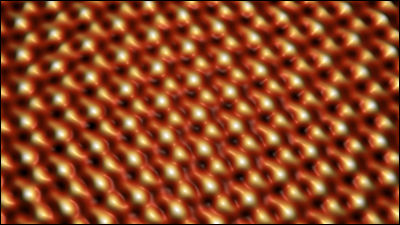

When producing graphene so far,Copper foilA raw material gas containing carbon is supplied onto the substrate heated to sample the graphene by a chemical reactionChemical vapor depositionI have taken the method of. When graphene sheets are commercialized, it is necessary to produce large quantities of graphene sheets at high speed and with high quality. However, ultra-thin films based on graphene produced by chemical vapor deposition are mostly of extremely small size.

Associate professor Hart said, "In order to industrialize graphene, we need to continually produce sheets of reasonable size, it is not good to produce just a few small pieces." It is said that development of the manufacturing method is aimed at future industrialization of graphene sheet.

bySantosh Gawde

The research team is a general industrial approach when producing thin film like material,Roll-to-roll methodAnd a general graphene manufacturing approach based on chemical vapor deposition to develop a method for producing high quality graphene in large quantities at high speed. The graphene making machine is equipped with two smallspoolAre connected by a belt conveyor.

A long copper foil with a width of less than 1 cm is wound on the first spool, and when the machine is in operation, when the copper foil wound around the first spool enters the tube in the furnace, the copper foil is ideal It is heated to temperature. After heating, the copper foil enters another tube in the furnace and feeds raw material gas containing methane or hydrogen synthesized in carbon or a specific ratio into the tube to produce graphene. Graphene is formed continuously on the copper foil, Associate Professor Heart tells us that it becomes one sheet. The manufactured graphene is said to be wound around the second spool.

The graphene manufacturing machine developed by Associate Professor Heart can operate up to 4 hours and can produce about 10 m of graphene as a continuous sheet. "In the case of factory production, it will be a system that continuously produces graphene for 24 hours," Associate Professor Hart said.

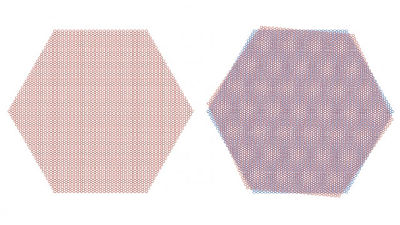

The graphene produced by the roll-to-roll method is said to roll up as it rolls freely if you leave it, and it can be used as a single sheet by supporting it with a porous polymer . Graphene produced by the research team by the new production method has filtration performance comparable to that of graphene produced in a small unit in the past and changes the quality slightly by changing the ratio of methane and hydrogen contained in the raw material gas It is possible to do.

Associate professor Hart said, "We have demonstrated that it is possible to scale up the process of manufacturing graphene, which raises the trust and interest in graphene and hopes that the way to commercialization will be opened "I said.

Related Posts: