Dyson opens "SG Technology Center" which expanded R & D base to Singapore, and what is "the future prospect" that Dyson draws?

Dyson, known for its origin as a cyclone vacuum cleaner, known as "Air Multiplier" with no blades and "Dyson Supersonic Hair Dryer" in a small compact air volume hair dryer,SG Technology Center (Singapore Technology Center)"Was newly established. The Singapore Technology Center, which was established to create an environment that enables research and development without fail for 24 hours in tandem with the headquarters in the UK, is aiming for "future integration of hardware and software", such as artificial intelligence, machine learning, robotics engineering, It is positioned as a core to create. Participating in the open event, I visited the Technology Center and was able to touch part of Dyson's "Perspective of the Future".

Arrived at "Singapore Technology Center" in Singapore.

The entrance is an open space.

Go to the venue where the opening ceremony will be held through the gate.

Preparation for the press conference was taking place.

Dyson products on the platform.

In the corner of the hall, a mini of Union Jack color is displayed on the roof.

Next to the cafeteria.

Usually this is the state.

This is a cafe that Dyson employees working at the Singapore Technology Center normally use, so they can order glass case sandwiches and bread.

Keynote Wait for the start of speech.

When I look up, suddenly, Dyson's "Cu-Beam (cue beam)It was used.

Dyson employees began gathering in the venue one after another.

Eventually it is in a tightly packed state.

◆ Keynote Speech

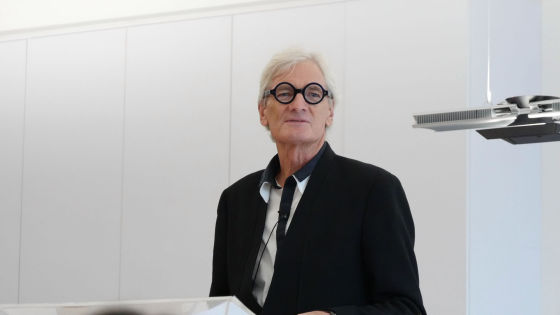

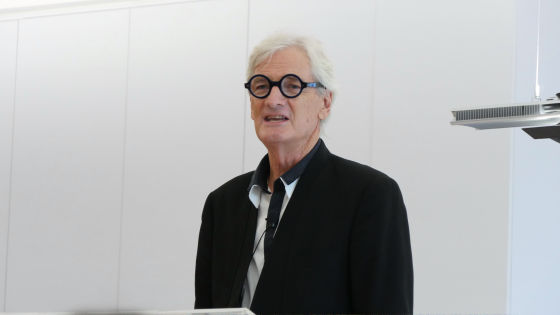

Following Jim Rowen COO, James Dyson's speech began.

Minister Iswaran (Minister of Commerce and Industry, Singapore), and all over the world. I am honored to be at the latest technology center.

Just ten years have passed since Dyson started working in Singapore with a small, limited engineering team. Our challenge was to develop and make the world's fastest digital motor. One of the few countries with the technology and supply chain necessary to develop such a complicated motor was Singapore.

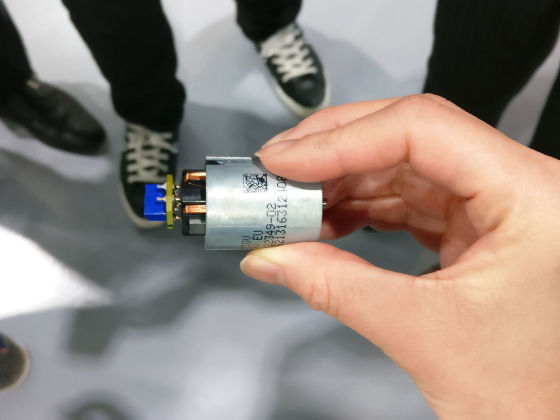

Let's take a look at the smallest digital motor "V9". This motor rotates 110,000 times per minute. It is 8 times faster than other motors with comparable performance and only half the weight. This V9 is set in the core of the hair dryer 'Dyson Supersonic Hair Dryer'. This motor is quiet because it rotates at supersonic speed. The motor is mounted on the handle part instead of the head part so that it is familiar with the hand and can balance it. It took four years of research and development and investment of £ 50 million (about 7.1 billion yen) for development. This Dyson Digital Motor V9 made it possible to fundamentally reconsider our daily products. Its internal mechanism is very elaborate and can be classified into military level. Therefore, special permission was required for export. We are now manufacturing 13 million motors a year in West Park, Singapore.

It is no coincidence that we are deepening our relationship with Singapore in order to make Dyson's "ambition in technology" a reality. We have excellent talented people all over the world. I hope that working together will create even more breakthroughs. New technology advances us as the digital motor did. Just as hardware is made of high precision parts, this motor is flooded with algorithms and code. Software drives hardware companies more quickly. It is very fast. This is more than speed to drive software companies. This power is created by two parts of software and hardware collaborating.

Therefore, our attention spans a wide range of fields. We will continue with artificial intelligence, machine learning, hardware / software, robotics engineering, fluid dynamics, vision system, battery cell, super capacitor, sound and list.

Dyson is focusing on developing highly intelligent technology. We are making products that you will know and expect before you actually do what you want. This "machine learning" gives our products intelligence to understand and respond to their environment. That is the center of our future. We are seeking the best intelligence. Singapore understands and appreciates the contribution of engineers to society. More importantly, there are graduates with highly skilled skills. Singapore's Prime Minister Lee stated, "Engineering is important to the future of Singapore." It is refreshing to be able to listen to such words from people in a leading position.

I believe that engineering is important for the future of everyone. The world is gripped by global technology competition. Only engineers can solve the most important problem. It has been known that pollution from automobile internal combustion engines is harmful. Air pollution affects everyone. It is even a wonderful modern state like Singapore. Engineers are removing the dangerous pollutants from our planet and actually preventing it at the forefront. This center is part of that fight. We are developing a next generation air cleaning technology that is connective (utilizing IoT). This technology keeps the air in our environment clean. In addition, we are studying batteries and digital motor technology. These will contribute to the future of clean energy.

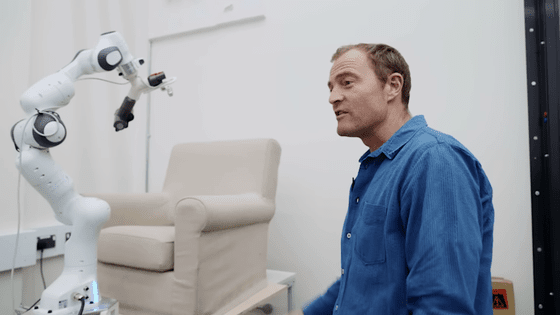

Robotics engineering is another worldwide opportunity. By improving the process of living, we have the power to change cities, homes and workplaces. Dyson's vision system in robot technology allows an automatic robotic vacuum cleaner to see and understand the surrounding environment. You can also learn about where the machine is from the image of 360 degrees around you, where you were, and places you have not yet done. It creates intelligence and high machine performance by fusing complex hardware and software. The power of this vacuum cleaner will reach Singapore's digital motor.

Dyson believes in engineers and believes in innovative technology. We invest in both engineers and technology, improve the environment and support them. Ultimately, "success" requires long-term investment and international prospects, and a political agenda to understand this philosophy. Singapore is clearly at the forefront of it, there is ambitions for the future. Dyson also holds the same ambition. I am very grateful to the Singaporean government and EDB. Exciting and creative things will happen. Thank you.

After the speech, we will shake hands firmly with Iswaran Minister who came to the opening ceremony of the Singapore Technology Center.

Dyson and Iswaran Minister to talk about hairdryer.

It was a scene that makes Dyson feel a close relationship with Singapore built in 10 years.

Mr. Dyson's message is not only a prospect for further raising the importance of Singapore in Dyson's product development but also a message that makes us feel the expectation for engineers working in Singapore and in any case it is a dyson's research base It became a form to appeal Singapore's importance both inside and outside.

◆ Technology Center · Tour

After keynote speech, we had a tour of the Singapore Technology Center, the second largest research and development facility after the UK. Reception space is like this.

Nonetheless, the Technology Center is a base to develop Dyson's technology, and photography of anything other than the space where Dyson products were exhibited is absolutely impossible.

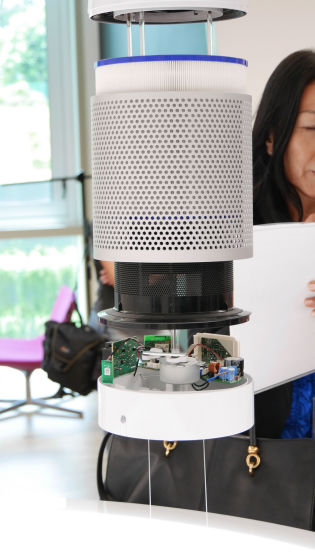

In the center of the exhibition space, a disassembly model of "Dyson Pure Cool Link Air Cleaning Fan" showing Dyson's technical capability as "fan without blades" is displayed, you can see the digital motor It was.

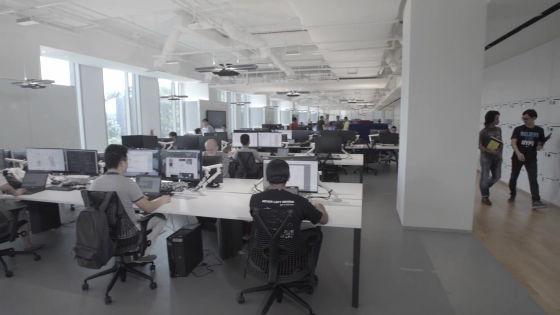

The office of the Singapore Technology Center is an open space with no partition.

Because I can work in my favorite places by free address system, it is said that engineers can open large and small meetings with each other.

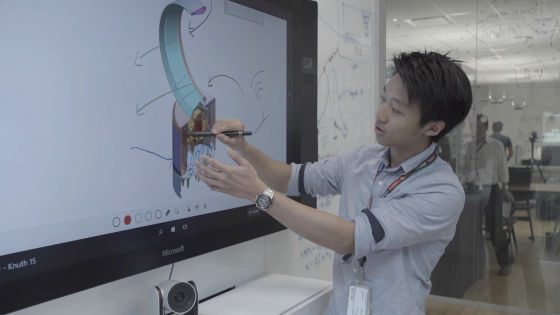

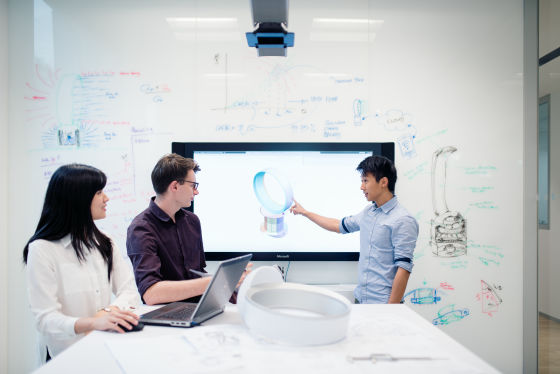

Meeting with a small number of people.

It seems that you are using Microsoft's Surface Hub.

There is also a desk with a brilliant partition such as blue or purple so that you can work intensively.

The standing desk style meeting room was able to write not only on the wall but also on the wall of the open glass. By the way, the meeting room is named as a great scientist mathematician, "Tim Berners-LeeThere was a room called. As Mr. Dyson gave a speech, Dyson, who has the strength as a hardware firm, has a big theme of "fusion of hardware and software", and from the naming of the meeting room, I was conscious of the importance of software engineering I can tell you that.

Office lighting is Dyson's LED lighting "Que Beam". Que Beam is a lighting developed by Mr. Jake Dyson, the eldest son of James Dyson. It is an LED light which realized a long life of 37 years by cooling the LED with a heat pipe. Incidentally Mr. Jake joins Dyson in 2015.

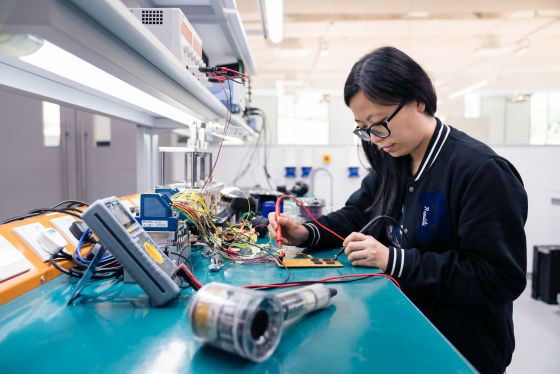

One of the major features of the Singapore Technology Center is the distance between the office and the development site.

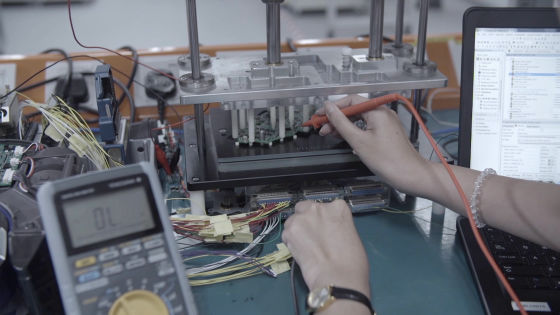

There are workspaces where engineers develop products in the immediate vicinity separated from the desk where the PC was placed with the door, and it is in an environment where ideas can be tried immediately. Every engineer repeats "failures" by practice, establishes new technology by learning it, and work to increase the level of the product is repeated endlessly.

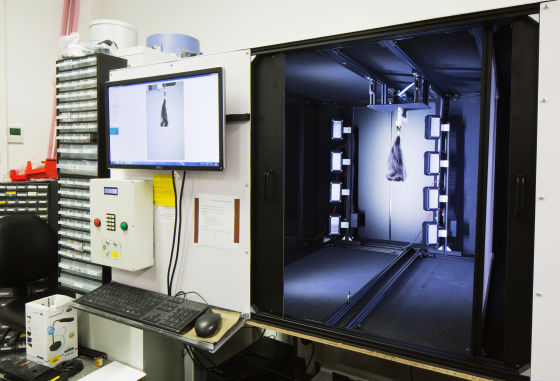

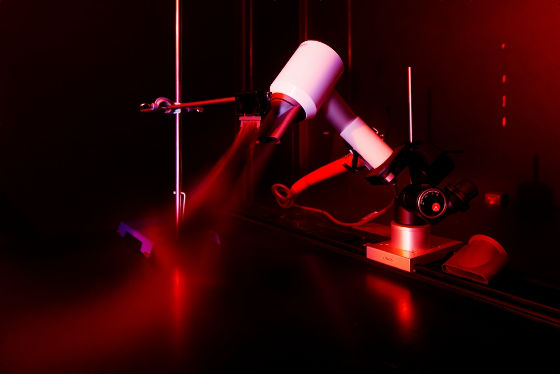

"Acoustic Lab (acoustic laboratory)" equipped with a semi-anechoic room was a glimpse of the thorough sticking to the "sound" of Dyson products. By providing a sound absorbing wedge (wedge) on the wall and ceiling, it realizes an anechoic environment that can remove echoes up to 100 Hz. Six hundred million Singapore dollar (about 1.8 billion yen) is invested in the acoustic laboratory which can verify the noise level, sound direction and sound quality by making use of a hemisphere equipped with 10 microphones, an intensity probe, and proprietary software It was said that it was. All Dyson products will be commercialized after being tested by this acoustic laboratory.

"Dyson Supersonic Hair Dryer" which is powerful but has less noise is also developed in this sound laboratory. I will check 80 items such as harmony, tone as well as noise. Through this thorough exam, despite the overwhelming large amount of wind, unlike a general dryer, the silence has been raised to the level that "you can talk while using" level. By the way, in a room separated from an anechoic chamber by a double door, a humanoid robot fitted with headphones named "Bob" records all the voice data generated by actually using the product It was.

Dyson Supersonic The commitment of the hair dryer is not limited to just the sound, but also pursues hair shine, smoothness, tension, etc. when used. It has been devised to prevent damage due to heat due to less bruised hair, the performance that satisfies professional stylists tells the quality of the machine.

Various analysis tests using exclusive equipment will be carried out. All the exams are done from a scientific point of view, and the data is displayed and visualized with numerical values and images.

Dyson Supersonic The important thing in determining the sound quality of a hair dryer is the impeller. In order to reduce the noise outside the wavelength that can be heard by the human ear, I improved the perception in one year. The noise was reduced by changing the number of 11 pieces of Pela to 13 sheets. Amazing improvements are also given to the details of the parts, and we will let you know the seriousness of Dyson standards.

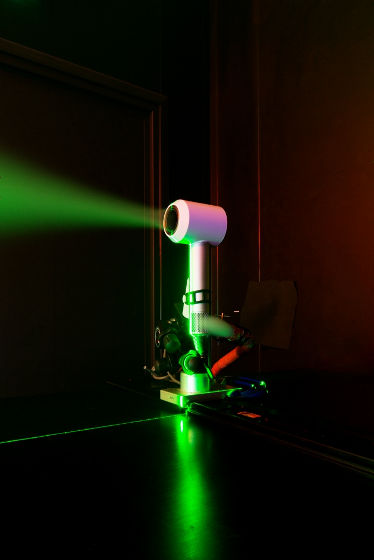

Chamber test to study air flow and air flow (air flow).

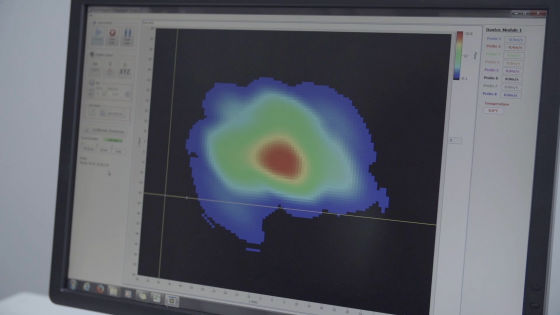

By mapping the air flow, we can visualize the invisible air flow.

Airflow actually has a big influence on the user's feeling when using a hair dryer. He says that by sending in a smooth and focused wind the hair design can be kept in an optimal condition and this was explained as being the basis of the technology of Dyson Supersonic hair dryer.

The quality of hair depends on race. In general there are differences between Asian hair with round cross-section hair and elliptical European people, curled cross-section flat hair, and he is testing hair of all patterns. In order to eliminate the variation cuticles are aligned, only the managed hair with exact matching colors is used for testing. "I did not understand the hair at all five years ago, I studied it to the level of" hair science "in the past 4 years," the engineer said.

In the environmental performance lab to investigate the durability of the product, the walls and ceiling were all covered with aluminum in order to enhance the heat dissipation of the whole room heated by accelerated real environment test.

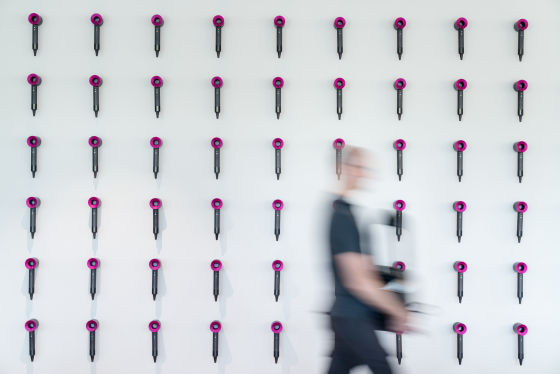

There are countless Dyson Supersonic hair dryers on the wall to the software department area, its name was "Supersonic Wall".

Dyson Supersonic Hair dryer is a proof that it possesses a level design that can also be used as an object.

Dyson's software development department, aiming to blend hardware and software,Dyson 360 Eye Robot Vacuum CleanerWas running around the "Connected Studio" which is a room reproduced assuming "home". A plurality of cameras and sensing devices are installed in the corner of the room, and the motion of the 360 Eye robot vacuum cleaner is checked. It seems that algorithm improvement and performance improvement will be introduced.

Connected studios are studying not only robotic vacuum cleaners but also all objects (connected devices) connected by the network, "technology sprouts" that are not yet commercialized, such as artificial intelligence, machine learning, vision systems, etc., are brought up .

There is also a permanent development area called "Future Lab" that was not allowed to enter. In Future Lab, it seems that engineers can work on confidential projects by escaping from the surrounding gaze, and can fully demonstrate the infinite range of imagination such as "putting clothes on a microwave oven" "floating a cup". If you are convinced that the idea that comes up is promising and thoroughly tested, and the result is felt by Mr. Dyson of the chief engineer, the project will be handed over to "New Product Development" It is said to start for realization.

Except for some digital motors, Dyson products are produced in Malaysia and the Philippines. The Singapore Technology Center which expanded the research and development function of the headquarters in England said that the development system will not be stopped for 24 hours. In addition, in Singapore geographically close to the manufacturing site in Malaysia and the Philippines, we have established a department to manage logistics called "control tower". A monitor capable of tracking the state of distribution in real time is installed, and it is required to control production and logistics. Dyson manufactures more than 13 million products in 2016 using more than 4 billion parts and sells it in 75 countries worldwide. The number of production has more than doubled in the past 4 years and will be doubled further in the next four years. The role that control tower plays to expand further production capacity seems to increase importance.

◆ West Park

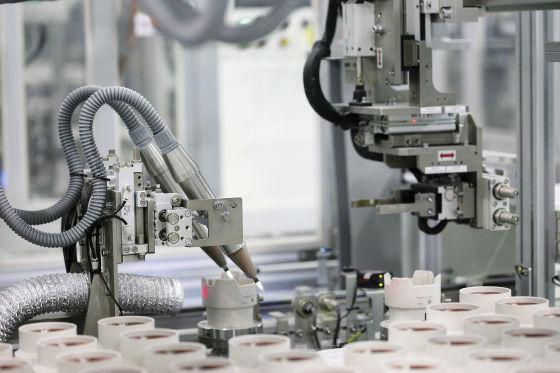

About 30 minutes by car from Singapore · Technology Center "West Park"We are manufacturing motors such as Dyson Digital Motor (DDM)" V9 "which is the heart of Dyson Supersonic hair drier. There are 250 million pounds (about 36 billion yen) invested in West Park, the manufacturing base of DDM, and DDM is manufactured at a rate of one in 2.6 seconds. Following the Singapore Technology Center, we also had a tour of the production line in the West Park, but the shooting was prohibited except for some of the manufacturing sites.

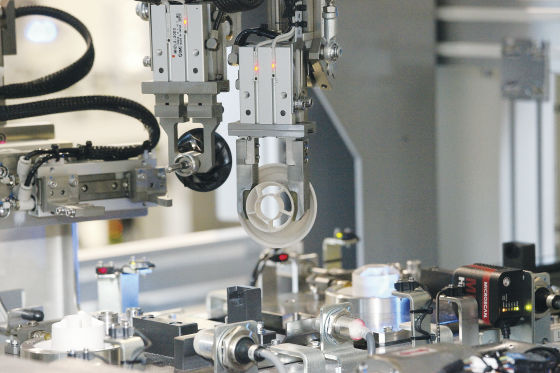

In the production line of "DDM V 6", the assembly of the bearing and the spring was done in the clean room. After that each part such as magnet, coil, impeller, frame (frame of motor) etc will be incorporated, but everything works with automatic robot. The automated robot that assembles the rotor and the frame has invested 300 million pounds (about 43 billion yen). Most of the robots assembled automatically were made in Japan. The assembled parts are checked for immediate balance. It can be confirmed that the parts which failed the test as "defective" from the robot are sorted into the red case, and it is necessary to have high precision in order to balance the axis of rotation of the small motor and the perilla I knew.

It is said that 13 million units of motor will be manufactured in West Park in one year. By the way, despite the vast area that manufactures DDM V6, it seems that only 15 people are operating.

That DM V6 or more has been made "unmanned" is the production line of "DDM V9" for the first time adopted by Dyson Supersonic hair dryer. Rotor manufacturing system is Kyushu'sHirata Machine CorporationDesigned. Other manufacturing equipments made in Japan were conspicuous.

Impeller of machined DDM V9. It is said that the quality control is carried out with a square bar code engraved on the bearing part with a laser. The surface of the pella is shiny without shining treatment.

It also barcodes the frame of the finished motor.

Incorporated impeller.

On the other side of the impeller is the control unit part. Brushless digital motor is rotated by 110,000 revolutions per minute with precise control.

A building that carries out containers by West Park. The digital motor made by West Park seems to be sent to Malaysia · Philippines promptly.

Dyson plans to invest £ 350 million (about 48 billion yen) in Singapore in the medium term. By the way, the Singapore Technology Center where the "control tower" which plays the role of grasping the situation of the manufacturing site in real time while expanding the research and development base which should also be called Dyson's brain from the head office in the UK is located in Singapore National University It is built next door. About 1,100 employees work at Dyson Singapore, about 350 of whom are engineers, but Dyson Singapore plans to hire talented people to make 50% of all employees engineers from now on.

Related Posts: