Successful creation of 3-dimensional structure that makes plastic more than 10 times stronger than iron using 3D printer

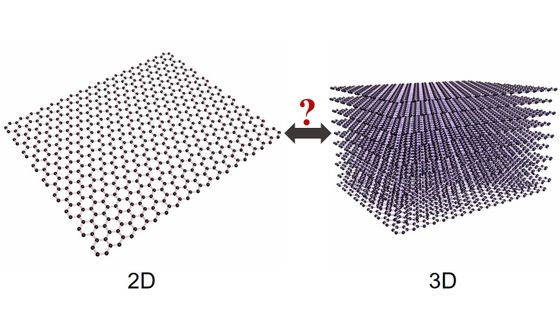

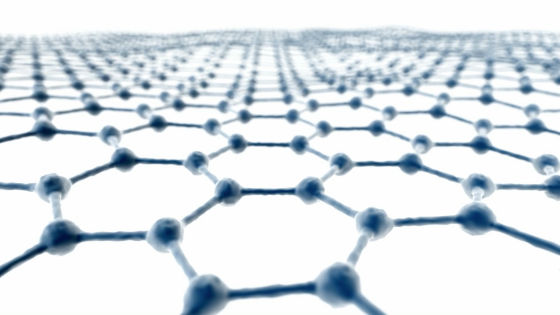

It spreads on the plane such that carbon atoms are connected to a regular hexagon "Graphene"Is the material of the dream that is expected to be able to realize a structure that gives high strength with overwhelming lightness with the substance with the highest strength on the earth. However, how to construct graphene with a two-dimensional structure three-dimensionally is a very difficult problem, and research is proceeding all over the world. Meanwhile, researchers at MIT worked on devising a structure to make graphene three-dimensional, and in a demonstration experiment using a 3D printer, succeeded in creating a three-dimensional structure that makes plastics 10 times stronger than iron. We have found the possibility to lighten and strengthen not only graphene but all kinds of materials.

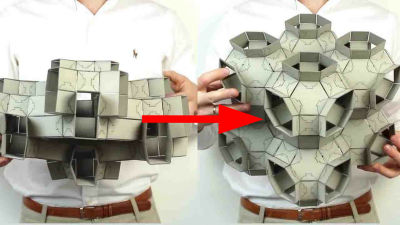

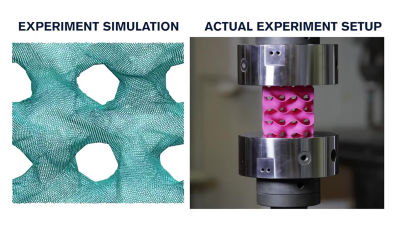

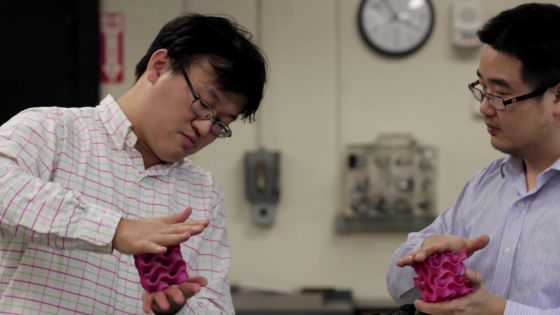

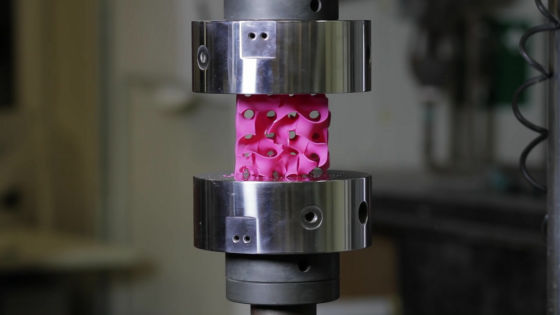

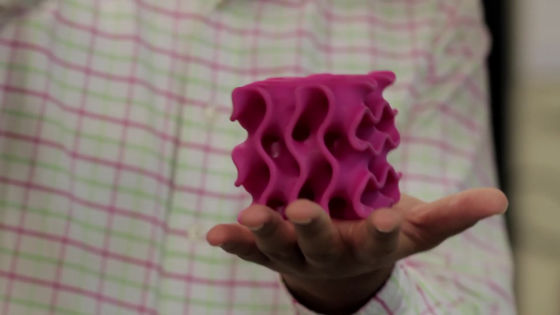

3-D-printed gyroid models such as this one tested the strength and mechanical properties of a new lightweight material.

http://news.mit.edu/2017/3-d-graphene-strongest-lightest-materials-0106

You can check how MIT researchers create super lightweight and high intensity objects using 3D printers in the following movie.

One of the strongest lightweight materials known - YouTube

Since graphene composed only of carbon atoms spreads into a sheet and has only one atom thickness, we are exploring ways to utilize the high strength of graphene.

The research team of MIT's Marcus · Buhler professor made experiments to measure the strength by creating a 3D model of the material using 3D printers.

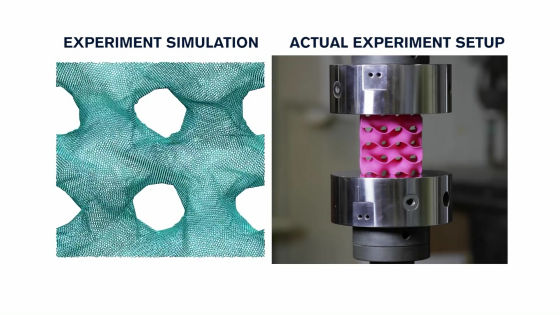

The left figure is a 3D model using a computer. It is a structure that becomes a solid by connecting regular hexagons imitating graphene while being distorted.

Calculation, in the scene where strong pressure is applied, it is said that the object should keep high strength while being dulled.

This model is made with resin using a 3D printer

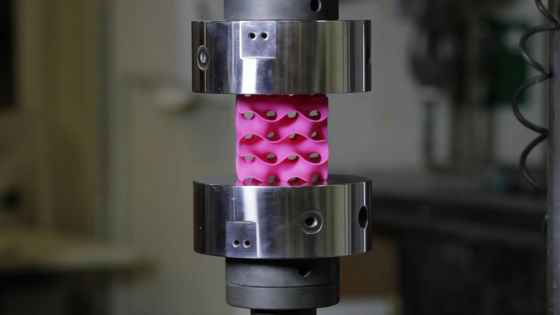

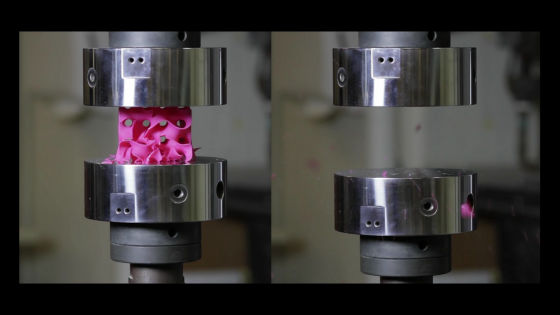

When applying pressure to the finished object from above and below and checking the strength ......

I will shrink so that the layer collapses from the bottom.

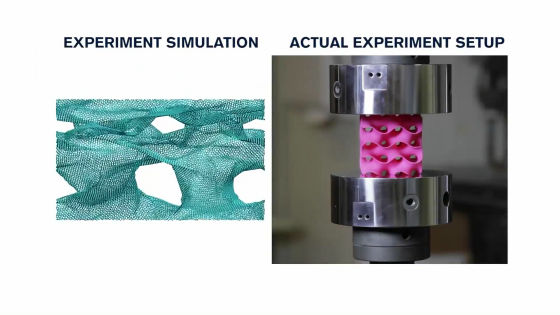

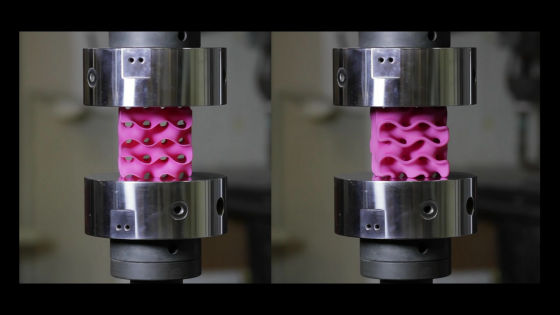

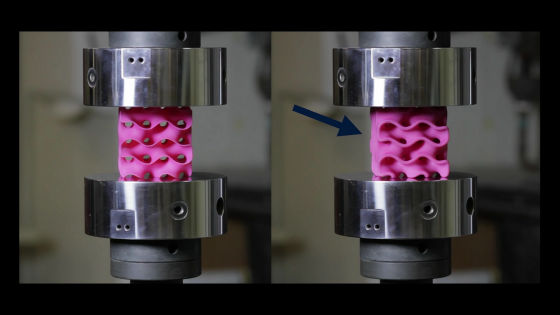

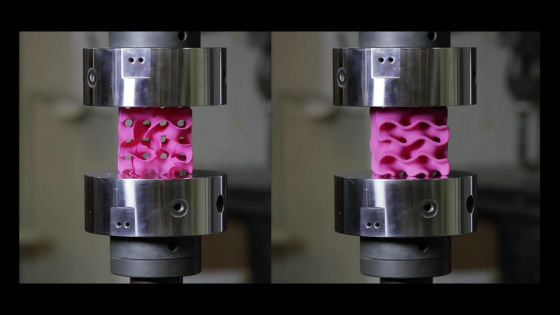

In the experiment, two patterns with different structure are created.

It should be noted that the three-dimensional object on the right.

While the three-dimensional object on the left deforms while shrinking so that the layer is crushed, while the right three-dimensional object shrinks slightly, the shape is maintained.

However, it was crushed to scatter at some point.

Even if you use the same resin material, you can see that the strength and crushing method are totally different characteristics.

Three-dimensional objects made by researchers at MIT have already succeeded in having 10 times the strength by 20 times the weight of iron.

Through demonstration experiments using 3D printers, even substances of the same material can be made into objects with completely different strength and toughness by changing the three-dimensional structure. Although research on this structure is an exploration of methodology for graphene stereoscopic, it can be applied to applications that make all materials light and strong.

Professor Buhler aims to finally graphene three-dimensionally. At the present time, after blowing graphene pieces on a solid object filled with space made of metal or resin, it is made of graphene by melting the metal / resin with heat It seems that we are studying the creation of structures with high strength.

Related Posts: