A movie that understands exactly where Apple has made three models of aluminum, iron and gold "Apple Watch"

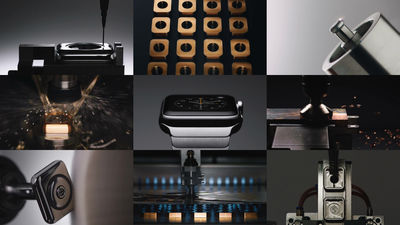

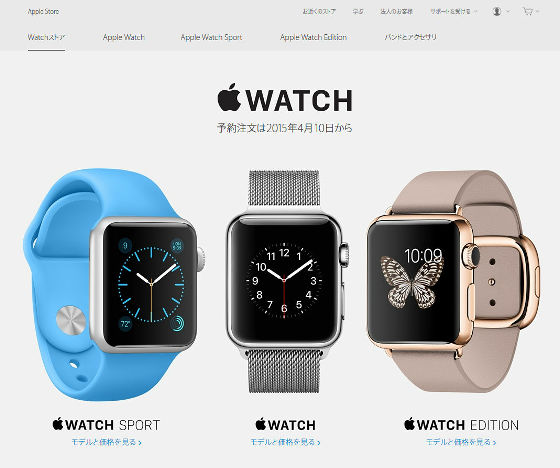

Apple's first smart watch that was decided to be released on April 24, 2015 is "Apple Watch"is. Apple events held on March 9, 2015 in local timeSpring forwardFormally withinRelease date and selling priceAnd others are revealed, "Apple Watch"Apple Watch Sport"Apple Watch Edition"It was announced that a variety of models will appear from the three models. Apple has published the manufacturing process of such Apple Watch in movies.

Apple - Apple Watch

http://www.apple.com/jp/watch/

First, check the manufacturing process of "Apple Watch Sport".

Apple Watch Sport - Aluminum - YouTube

Aluminum is used for the case part of the Apple Watch Sport.

Because aluminum is tough and light, it can be said that it is perfect for Apple Watch Sport.

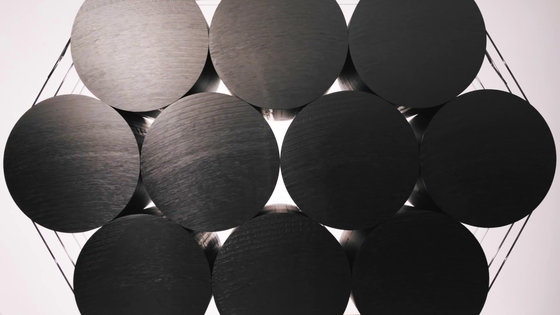

Apple engineers have created a new alloy "7000 Series Aluminum" to make it more durable than normal aluminum.

It is 60% stronger than the standard aluminum alloy ......

Very lightweight.

What is needed to create this alloy ......

It is a very precise alloying process.

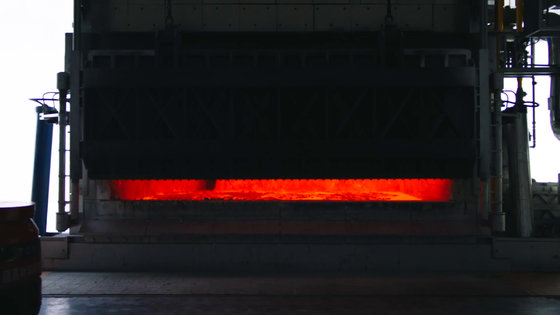

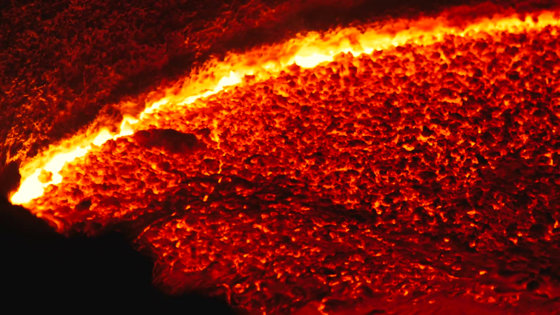

First melt high purity aluminum ......

Mix with strictly controlled magnesium and zinc ......

These become hardened and become a very strong alloy.

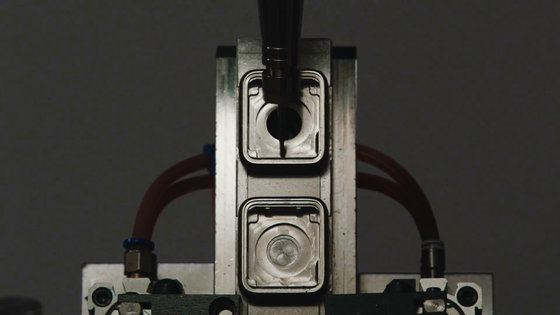

Then pour the alloy into the mold and cool it rapidly.

By high-temperature treatment, steel pieces are minimized to make it uniform and uniform.

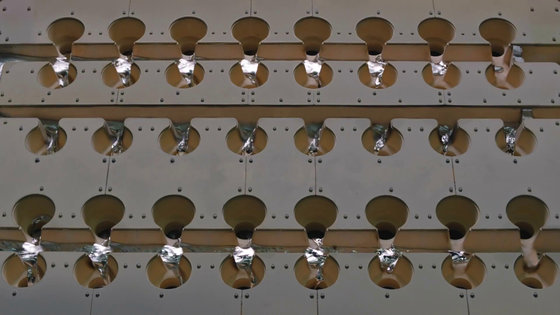

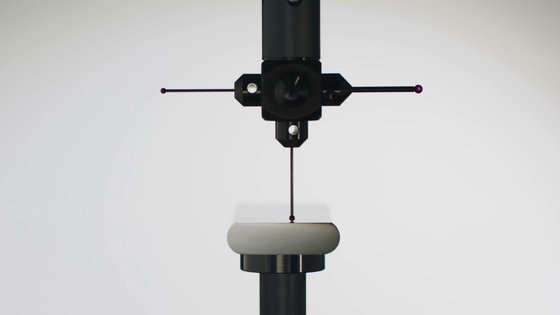

Next, the surface of the alloy is uniformly treated using a jetting device.

In this way, we carefully carefully chop out the finished kore, and the enclosure of Apple Watch Sport will be completed.

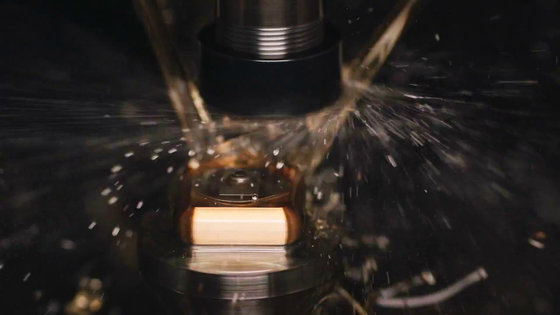

Each chassis is machined ... ...

You can polish.

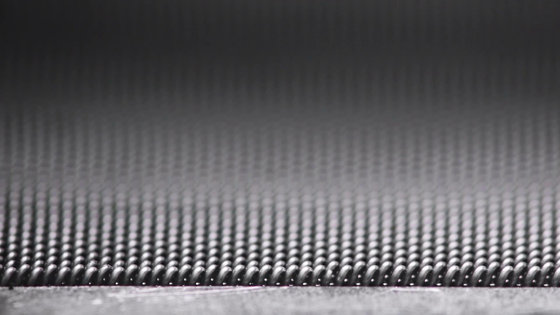

And by spraying fine zirconia grains ......

To finish with shiny feeling.

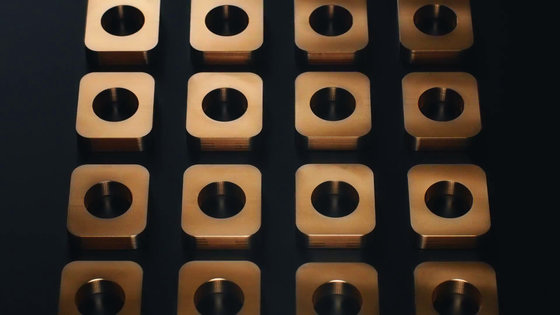

The parts of the enclosure that was completed in this way is kore.

Finally, in order to finish the cabinet parts more rugged and beautiful appearance, we put in the liquid for oxide film treatment. With this process, Apple Watch Sport is likely to be resistant to scratches and shocks.

Casing parts after oxide film treatment look like this.

Parts of the crown are also being crispy ......

A line of the dragon head portion is digging one by one.

It is the kore completed.

Apple Watch Sport

Then I will take a closer look at the manufacturing process of "Apple Watch".

Apple Watch - Steel - YouTube

The casing part of the Apple Watch is made of stainless steel. The reason why stainless steel is used is because it is strong and looks beautiful.

Even in past watches, stainless steel has been used for the same reason.

Stainless steel used for Apple Watch also has a special manufacturing method.

The stainless steel we are using is strong and rust resistant "316L stainless steel".

And it seems that finishing to a more rugged material by devising the forging process.

At the stage of dissolving the first metal, the blending of the metal is strictly controlled.

Impurities are kept to a minimum, keeping the hardness as high as possible.

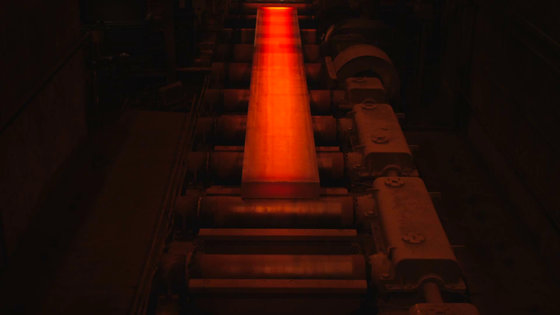

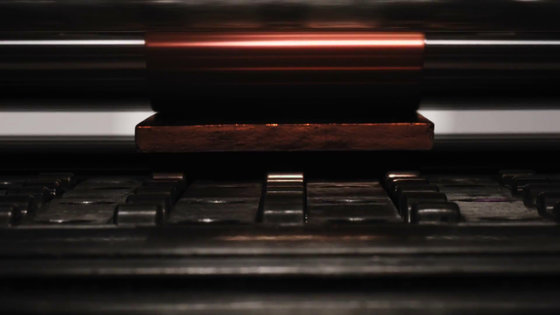

And finished lumps of metal ......

Cold forging. This will make stainless steel harder by up to 80%, and it will be resistant to scratches.

The enclosure is gradually shaved out by a plurality of machines ... ...

It becomes very elaborate housing parts.

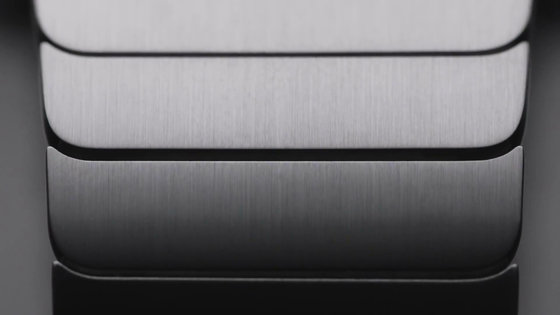

And polishing with a machine gives a mirror finish.

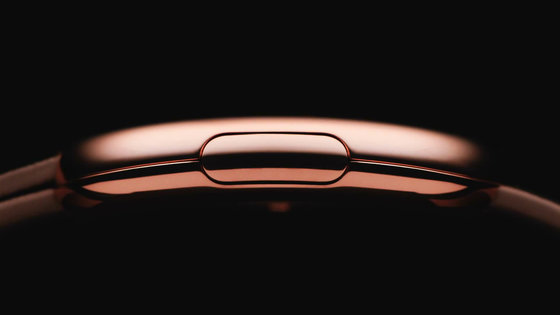

This is a housing part with mirror finish.

In the case of space black, in addition to these processes, diamond-like carbon is coated on the surface.

Likewise, Apple manufactures metal parts of the band part with commitment.

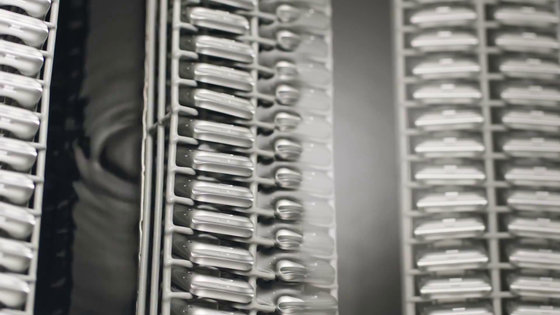

This band is completed by connecting 140 parts ......

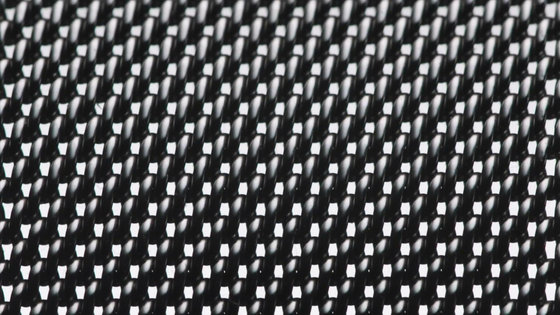

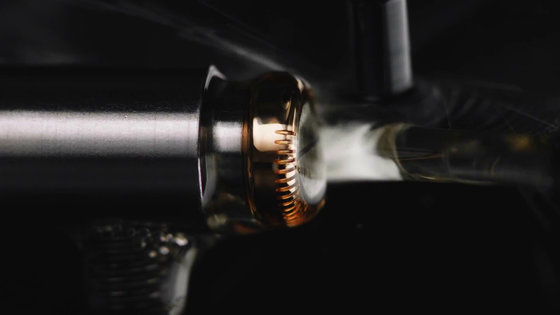

Metal mesh bands are made by weaving stainless steel coils.

So it looks like a beautiful fabric.

By combining these parts, a beautiful Apple Watch made of stainless steel is completed.

Finally the production process of the high-end model "Apple Watch Edition" using 18 gold.

Apple Watch Edition - Gold - YouTube

The casing material of Apple Watch Edition is gold.

It seems that he decided to manufacture Apple Watch Edition so that it can be adapted to a wide range of individual styles.

The gold used is yellow and rose gold two colors. Of course, both of the two colors are taking a special manufacturing method, not only is it looking beautiful but it is also stronger than normal gold.

By adjusting the amounts of silver, copper and palladium precisely at the molecular level first and then mixing ... ...

Make it a special color.

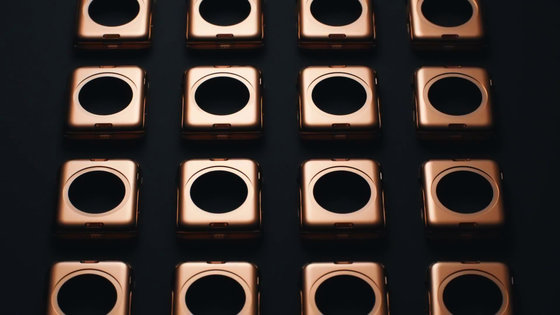

Then, pour the gold melted by the method developed by Apple's metallurgical expert into the mold and create the ingot

Grinding the ingot surface gently ... ....

I will press it.

With this, gold parts without gaps are completed.

In addition, inspection of metal parts for several minutes using ultrasonic scanner.

If there is no quality problem, we will cut the parts one by one.

The dragon head part also looks different from other Apple Watch in processing method.

Each part has a sense of quality that distinguishes it from other Apple Watch.

The enclosure parts are finally polished with human hands, and finished in a beautiful appearance that is not cloudy.

Completed in this way is Apple Watch Edition that combines ruggedness and beauty.

If you include Apple Watch 3 model, 2 body sizes and even a list band combination, there are 38 options in total, so you can check the selling prices for each combination from the following articles.

Detailed summary of "Apple Watch" in Japan and all 38 models, models with more than 2 million yen - GIGAZINE

Related Posts: